RM500B

RM500B Rotary Mixer

DESCRIPTION

Enhancements and versatility make this durable industry workhorse an exceptional value. High production and excellent production quality go hand-in-hand with low operating and maintenance costs.The RM500B Rotary Mixer combines superior performance and reliability to achieve the most demanding job specifications while maximizing machine uptime. With many enhanced features and options, the RM500B is designed to work well in both full depth reclamation and soil stabilization applications.Cat® C15 Engine

The C15 engine provides a gross power (SAE J1995) of 407 kW (546 hp). The combination of large displacement and high torque allow the RM500B to propel through the toughest materials. The engine meets US EPA Tier 4 Final and EU Stage V emission standards.

Reversible Cooling Fan

The cooling fan is reversible and automatically performs periodic cycles in reverse to clean the heat exchanger by expelling accumulated dust. This allows the system to cool more efficiently, ensuring optimal engine performance.

Four Propel Pumps, Four Drive Motors

Four propel pumps provide separate, dedicated flow to all four drive motors. Provides superior tractive effort in soft underfoot conditions.

Iso-mounted Cab is Pressurized

Iso-mounted cab reduces vibration and is pressurized to maximize comfort by keeping noise, dust and the elements out.

Sliding Cab

Cab slides left and right and can be positioned to maximize visibility.

Reliable Field-proven Technology

Reliable field-proven technology provides maximum productivity and simplifies troubleshooting.

Cat Powershift Transmission

A Cat powershift transmission drives the rotor and is sized to handle tough cutting and deep mixing.

Mixing Chamber

Mixing chamber allows the rotor to move independently so that the capacity of the chamber actually increases in deeper cuts to allow better material mixing.

Hydraulically Operated Front Door

Hydraulically operated front door allows the operator to control the opening of the front door from the operator's station.

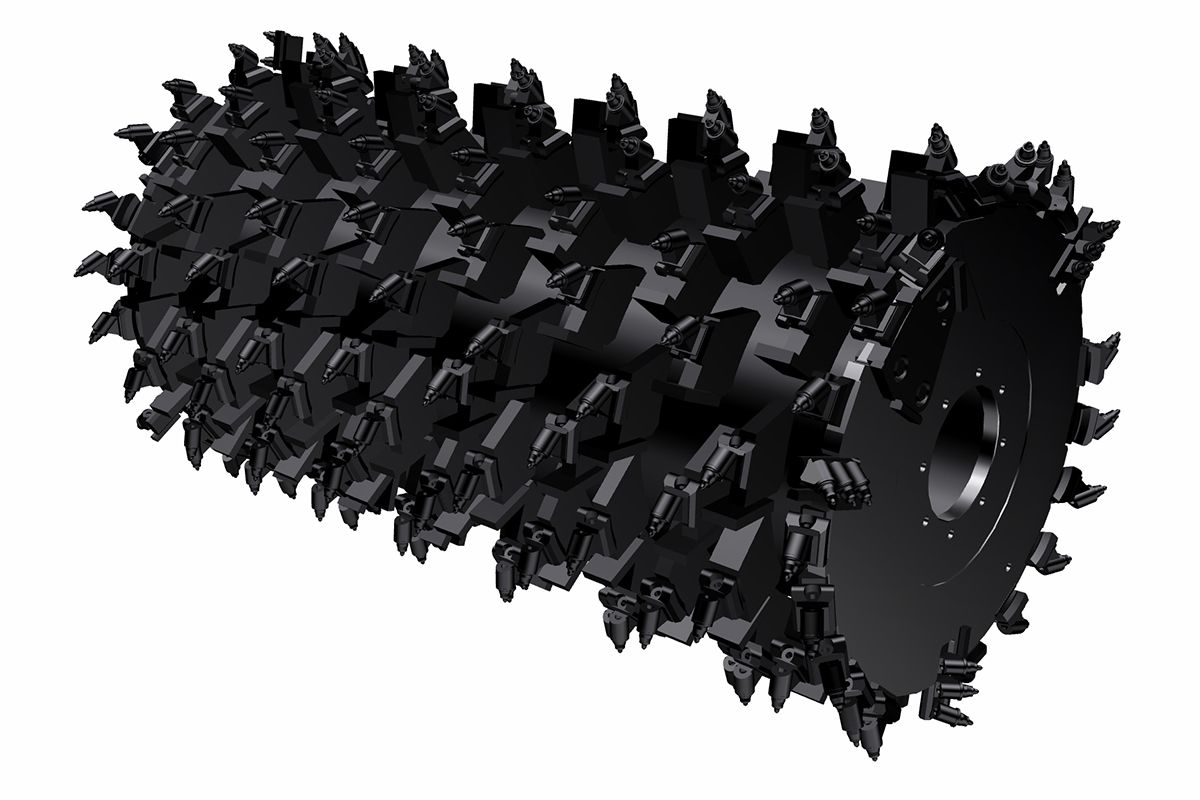

Universal 16 Rotor

The Universal 16 rotor is designed to produce maximum breakout force in deep asphalt cuts and on existing soil cement. It also performs well in soil stabilization applications.

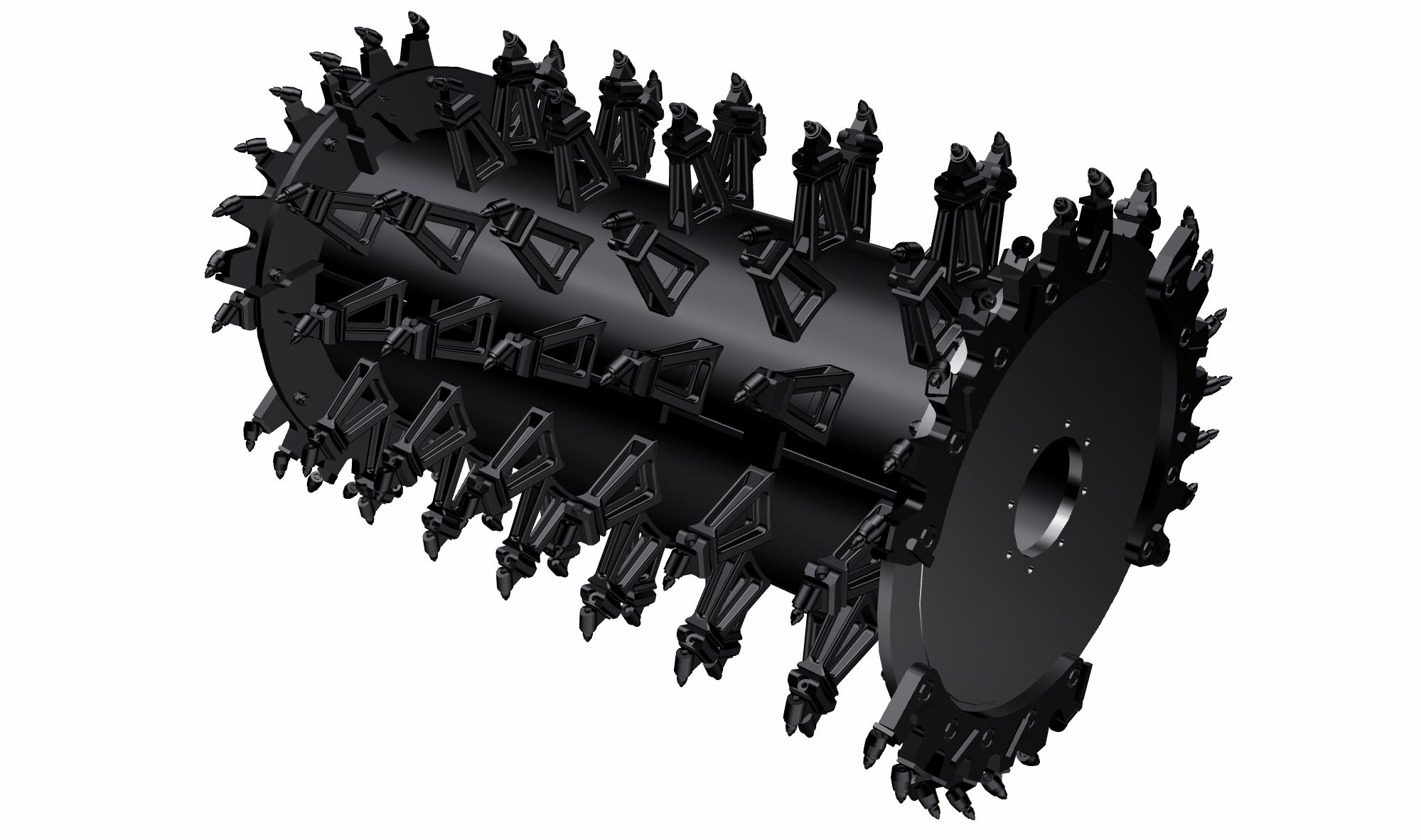

Combination Rotor

The Combination rotor is designed for deep-cut soil mixing where pulverization and gradation is of lesser importance and higher working speeds are more important. It performs well in cohesive soils and has a secondary application of surface mining for non-engineered substances such as coal, shale, or limestone.

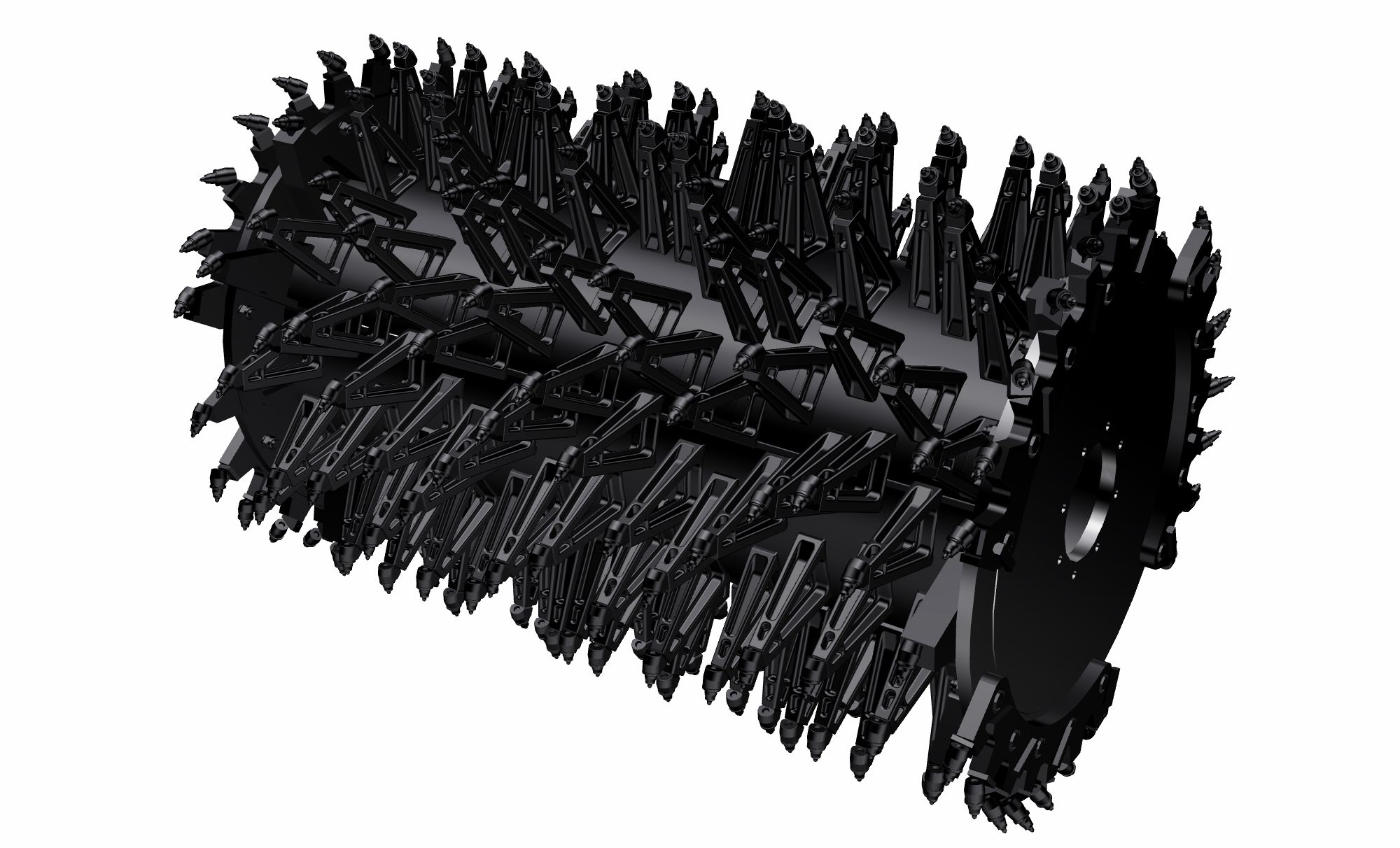

Soil Rotor

The Soil rotor is an ideal choice for mixing additives with semi cohesive or granular materials where soil gradation is critical. It can also handle light reclamation applications where the asphalt layer is thin and deteriorated.

Hydraulic Rotor Hood Tilt

Hydraulic rotor hood tilt rotates hood forward for convenient access to rotor for inspection and tool maintenance.

- Optional Equipment

- Specs

- Docs

Optional Equipment

Specs

Overview

Weights

Operating Specifications

Engine

Dimensions

Service Refill Capacities

SEE HOW RM500B COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Caterpillar

- Status

- Current

- Maximum Operating Weight

- 62611 lb / 28400 kg

- Cutting/Mixing Width

- 96 in / 2438 mm

- Rotor Speed - Third (at 2100 Engine rpm)

- 205 r/min / 205 r/min

- Maximum Travel Speed

- 6.2 mile/h / 10 km/h

- Operating Speed

- 2 mile/h / 3.2 km/h

- Rotor Options

- Universal, Combination, Soil

- Rotor Speed - First (at 2100 Engine rpm)

- 110 r/min / 110 r/min

- Rotor Speed - Second (at 2100 Engine rpm)

- 152 r/min / 152 r/min

- Maximum Cutting/Mixing Depth

- 20 in / 508 mm

- Gross Power

- 546 HP / 407 kW

- Engine Model

- C15

- Ground Clearance

- 19.9 in / 506 mm

- Width

- 9.58 ft / 2.98 m

- Length

- 33.83 ft / 10.32 m

- Wheel Base

- 21.33 ft / 6.55 m

- Maximum Height

- 11.78 ft / 3.59 m

- Fuel Tank Capacity

- 279 gal (US) / 1056 l

- Brand

- Caterpillar

- Status

- Current

- Maximum Operating Weight

- 57682 lb / 26164 kg

- Cutting/Mixing Width

- 96 in / 2438 mm

- Rotor Speed - Third (at 2100 Engine rpm)

- 159 r/min / 159 r/min

- Maximum Travel Speed

- 6.8 mile/h / 11 km/h

- Operating Speed

- 2.97 mile/h / 4.8 km/h

- Rotor Options

- Universal, Combination, Spade

- Rotor Speed - First (at 2100 Engine rpm)

- 108 r/min / 108 r/min

- Rotor Speed - Second (at 2100 Engine rpm)

- 134 r/min / 134 r/min

- Maximum Cutting/Mixing Depth

- 20 in / 508 mm

- Gross Power

- 415.7 HP / 310 kW

- Engine Model

- Cat C9.3B

- Ground Clearance

- 19.7 in / 500 mm

- Width

- 9.8 ft / 3 m

- Length

- 31.4 ft / 9.56 m

- Wheel Base

- 20.7 ft / 6.32 m

- Maximum Height

- 11.5 ft / 3.5 m

- Fuel Tank Capacity

- 279 gal (US) / 1056 l