C7.1

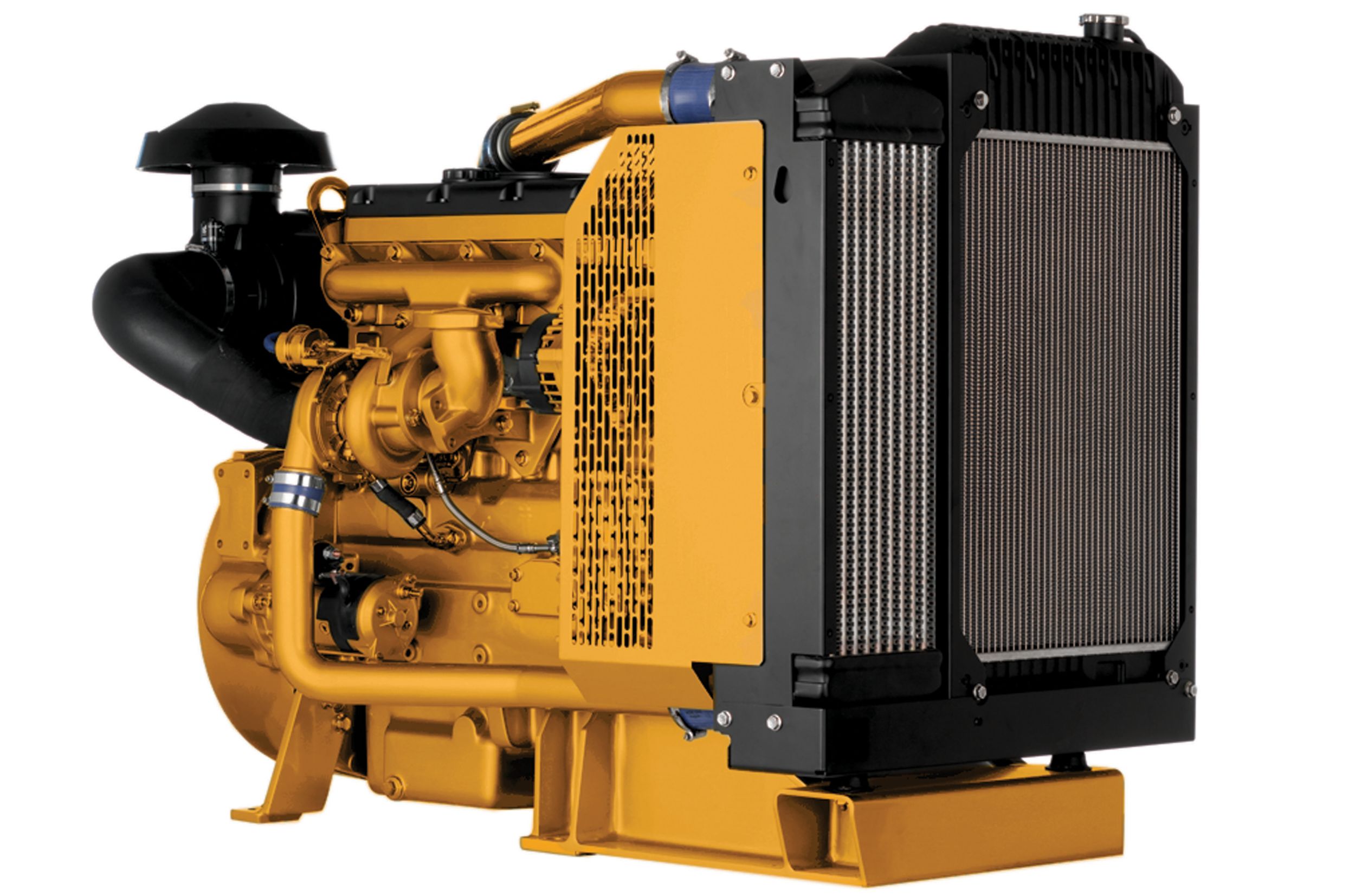

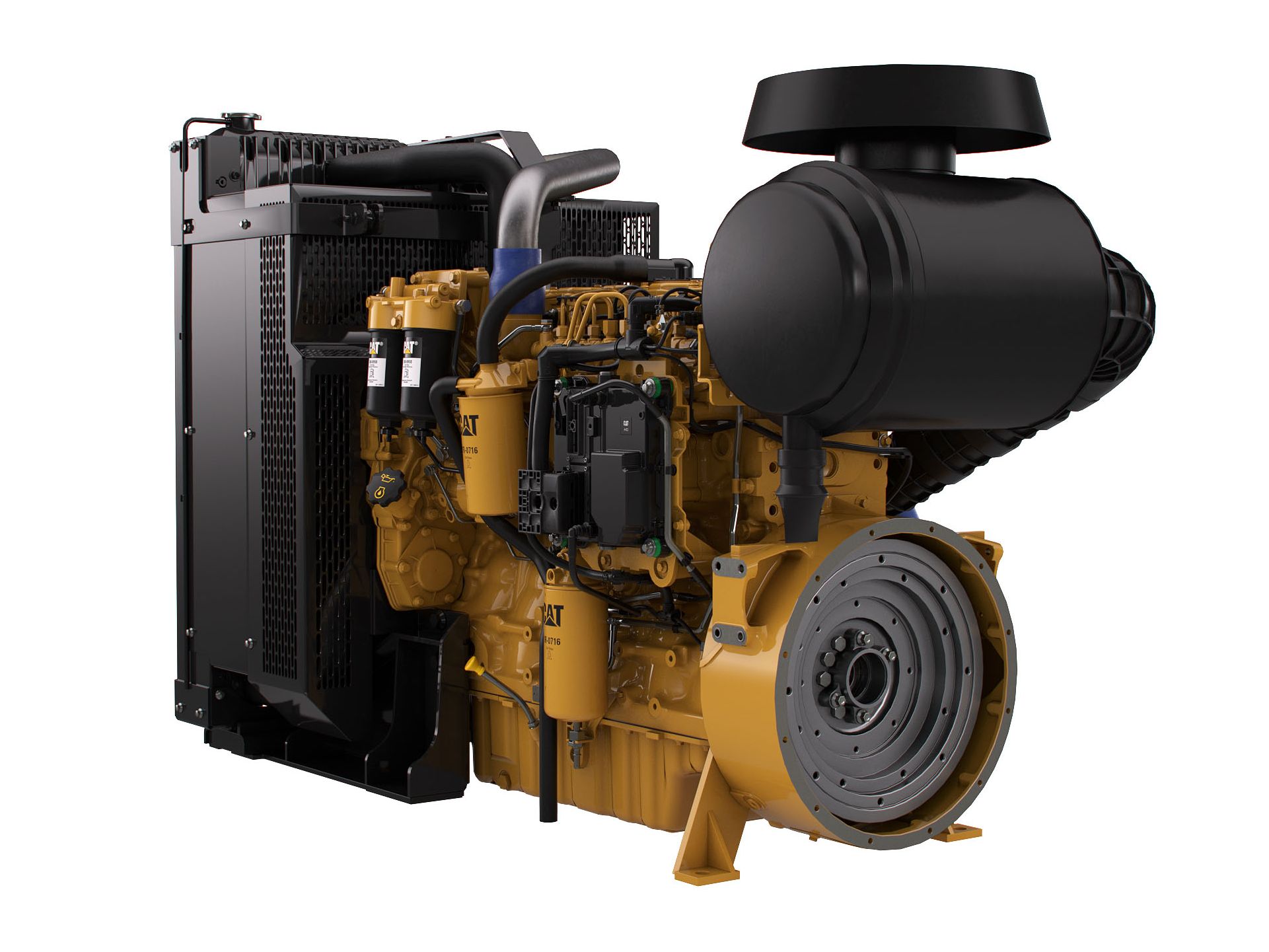

Cat? Unidad de potencia industrial C7.1

DESCRIPCIÓN

La unidad de potencia industrial C7.1 se ofrece en potencias que van desde 151 a 225 kW (202 a 302 hp) a 1800 a 2200 rpm. Estas potencias cumplen con las normas de emisiones Tier 4 Final de la EPA de EE. UU., Stage IV de la UE y Japón 2014 (Tier 4 Final). Preconfigurada de forma práctica para una amplia gama de aplicaciones.cationes, los CatLa unidad de potencia industrial es un paquete de potencia completo que contiene un radiador, un volante, un alternador y un cableado del alternador completamente preensamblados para una instalación rápida y sencilla en una serie de aplicaciones OEM, de clientes y de empaquetadores.catEstas unidades de bajo consumo de combustible están listas para su uso en aplicaciones de bombeo de riego, industriales, mineras y otras.catLa unidad de potencia industrial C7.1 se ofrece en potencias que van desde 151 a 225 kW (202 a 302 hp) a 1800 a 2200 rpm. Estas potencias cumplen con las normas de emisiones Tier 4 Final de la EPA de EE. UU., Stage V de la UE y Japón 2014 (Tier 4 Final). Preconfigurada de manera conveniente para una amplia gama de aplicaciones.cationes, los CatLa unidad de potencia industrial es un paquete de potencia completo que contiene un radiador, un volante, un alternador y un cableado del alternador completamente preensamblados para una instalación rápida y sencilla en una serie de aplicaciones OEM, de clientes y de empaquetadores.catEstas unidades de bajo consumo de combustible están listas para su uso en aplicaciones de bombeo de riego, industriales, mineras y otras.cationes.Energía industrialEnergía confiable, silenciosa y duradera

La capacidad y los procesos de fabricación de clase mundial junto con diseños de motores centrales probados garantizan confiabilidad, funcionamiento silencioso y muchas horas de vida productiva.

Alto Rendimiento

Turbocompresor en serie con válvula de descarga inteligente disponible en clasificaciones específicas para una respuesta rápida, alta potencia y mayor torque.

Eficiencia de combustible

Consumo de combustible optimizado para adaptarse a los ciclos operativos de una amplia gama de equipos y aplicaciones.cationes manteniendo bajos costos operativos.

Gasolina

Los motores Tier 4 Final, EU Stage V y Japón 2014 (Tier 4 Final) requieren combustible diésel con contenido ultrabajo de azufre (ULSD) que contenga un máximo de 15 ppm de azufre y nuevas formulaciones de aceite para respaldar la nueva tecnología. Cat® Los motores están diseñados para admitir el biocombustible B20. Cat El concesionario puede proporcionar más información sobre el combustible y el aceite.

Amplia aplicacióncatRango de iones

Gama líder en la industria de clasificaciones y opciones configurables de fábrica para aplicaciones agrícolas, de manejo de materiales, de construcción, de minería, de soporte terrestre para aeronaves y otras aplicaciones industriales.cationes.

Tamaño del paquete

La densidad de potencia excepcional permite la estandarización en numerosas aplicaciones.catIones. Múltiples opciones de instalación que minimizan el tamaño total del paquete. Ideal para equipos con compartimentos de motor estrechos.

Soporte de productos de clase mundial ofrecido a través de Global Cat Nuestra red de distribuidores

- Mantenimiento programado, incluido SOSSM muestra

- Acuerdos de soporte al cliente (CSA)

- Caterpillar Cobertura de servicio extendida (ESC)

- Red de servicio de distribuidores superior

- Red de servicio de distribuidores ampliada a través de Cat Programa de Distribuidor de Servicios Industriales (ISD)

- Equipamiento estandar

- Especificaciones

- Docs

Equipamiento estandar

- Entrada de aire

- Purificadores de aire estándar

- Sistema de control

- Sistema de control electrónico completo, todos los conectores y mazos de cables son impermeables y están diseñados para soportar entornos todoterreno hostiles.

- Las funciones de software flexibles y configurables y el bus CAN SAE J1939 con buen soporte permiten máquinas altamente integradas

- Sistema de refrigeración

- Temperatura del tanque superior 108 °C (226 °F) como estándar para minimizar el tamaño del paquete de enfriamiento

- Mezcla de agua y glicol 50:50

- Orientación sobre el diseño del sistema de enfriamiento disponible a través de su distribuidor para garantizar la confiabilidad del equipo

- Volantes y carcasas de volantes

- Amplia variedad de interfaces de transmisión, incluidas configuraciones SAE No. 1, SAE No. 2 y SAE No. 3

- Sistema de Combustible

- Common Rail electrónico de alta presión

- Sistema de lubricación

- Amplia gama de cárteres para diferentes aplicaciones.cationes

- Generalidades

- Pintura: Caterpillar Amarillo, con colores opcionales disponibles a pedido.

- Equipos de postratamiento/control de emisiones limpias Tier 4 Final de la EPA de EE. UU., Etapa V de la UE, Japón 2014 (Tier 4 Final)

- Módulo de emisiones limpias (CEM), compuesto por un filtro de partículas diésel (DPF) y un sistema de oxidación diésel. CatAnalista (DOC)

- Sistema de reducción de NOx (NRS)

- Selectivo CatReducción analítica (SCR)

- Conexión de tubería flexible de 3" con opciones rectas, de 45° y 90° para mayor flexibilidad

Especificaciones

Descripción General

Potencia nominal

Estándares de emisión

Generalidades

Dimensiones de la unidad de potencia

Dimensiones del postratamiento

VEA CÓMO SE COMPARA C7.1 CON PRODUCTOS QUE SE COMPARAN CON FRECUENCIA.

- Marca

- Caterpillar

- Estado

- Current

- Poder maximo

- 302 CV / 225 kW

- Velocidad nominal

- 1800-2200 XNUMX rpm

- Potencia mínima

- 202 CV / 151 kW

- Emisiones

- EPA de EE. UU., nivel 4 final, fase V de la UE, Japón 2014 (nivel 4 final)

- Configuración del motor

- Diésel de 6 tiempos y 4 cilindros en línea

- taladro

- 4.1 pulgadas/105 mm

- Recorrido

- 5.3 pulgadas/135 mm

- Desplazamiento

- 427.7 pulgadas cúbicas/7.01 l

- Índice de compresión

- 16.5:1

- Aspiración

- Serie Turboalimentado y postenfriado (TTA)

- Rotación desde el extremo del volante

- En sentido antihorario

- Después del tratamiento

- DOC+DPF+SCR

- Longitud Mínima

- 30.4 pulgadas/771 mm

- Ancho

- 31.2 pulgadas/793 mm

- ALTO

- 18.4 pulgadas/468 mm

- Ligero

- 198 libra / 90 kg

- Marca

- Caterpillar

- Estado

- Current

- Poder maximo

- 108.6 CV / 81 kW

- Velocidad nominal

- 2200 XNUMX rpm

- Potencia mínima

- 81.8 CV / 61 kW

- Emisiones

- Normativa CEPE R96 Etapa IIIA

- Configuración del motor

- Diésel de 4 tiempos y 4 cilindros en línea

- taladro

- 4.1 pulgadas/105 mm

- Recorrido

- 5 pulgadas/127 mm

- Desplazamiento

- 268.5 pulgadas cúbicas/4.4 l

- Índice de compresión

- 18.2:1

- Aspiración

- Turboalimentado (T)

- Rotación desde el extremo del volante

- En sentido antihorario

- Después del tratamiento

- -

- Longitud Mínima

- 49.6 pulgadas/1260 mm

- Ancho

- 28.9 pulgadas/734 mm

- ALTO

- 38 pulgadas/964 mm

- Ligero

- 1025 libra / 465 kg

- Marca

- Caterpillar

- Estado

- Current

- Poder maximo

- 275 CV / 205 kW

- Velocidad nominal

- 116-205 bkW/156-275 bhp a 2200 rpm, 129 bkW/173 bhp a 2500 rpm

- Potencia mínima

- 156 CV / 116 kW

- Emisiones

- China Nonroad Stage III, Brasil MAR-1, UN ECE R96 Stage IIIA

- Configuración del motor

- Diésel de 6 tiempos y 4 cilindros en línea

- taladro

- 4.1 pulgadas/105 mm

- Recorrido

- 5.3 pulgadas/135 mm

- Desplazamiento

- 427.7 pulgadas cúbicas/7.01 l

- Índice de compresión

- 16.8:1

- Aspiración

- Turboalimentado y postenfriado (TA)

- Rotación desde el extremo del volante

- En sentido antihorario

- Después del tratamiento

- -

- Longitud Mínima

- 68 pulgadas/1728 mm

- Ancho

- 31 pulgadas/788 mm

- ALTO

- 44.8 pulgadas/1140 mm

- Ligero

- 1737 libra / 788 kg