140 LVR

140 Motor Grader

The Cat® 140 Motor Grader offers fuel-efficient performance, all-wheel drive, and advanced Cat Grade technology for precise road building and site prep.

DESCRIPTION

The Cat® 140 motor grader is a mid-size machine ideal for road maintenance. It delivers the right balance of power, control, and blade reach for grading, crowning, and ditching on gravel, rural, and secondary roads.The Cat® 140 motor grader is a mid-size machine ideal for road maintenance. It delivers the right balance of power, control, and blade reach for grading, crowning, and ditching. Maintain your gravel, secondary roads in comfort with the redesigned cab.Meet the Next Generation Cat® 140 Motor Grader

Redesigned Cab

The redesigned cab provides better visibility to the ground, rear visibility, grouped control buttons for ease of operations, optional seat upgrades, and comfort customizations for the operator.

Safety

- Operator presence monitor keeps the parking brake engaged and hydraulic implements disabled until the operator is seated and the machine is ready for operation.

- Anti-glare paint eases night operation.

- Ground-level refueling requires no climbing on the machine to fill the fuel tank.

- Ensure three points of contact when entering and existing the machine with strategically placed walkways and grab rails.

- Work past sundown using the standard LED light package for increased nighttime visibility.

- Speed Sensitive Steering lessens steering sensitivity as ground speed increases for greater operator confidence and control.

- The optional Secondary Steering System's electric hydraulic pump automatically engages in case of a drop in steering pressure to ensure operator can steer the machine to a stop.

- Hydraulic lockout disables all implement functions while still providing machine steering control. Especially useful while roading.

- Brakes are located at each tandem wheel to eliminate braking loads on the powertrain. Redundant brake systems utilize accumulators to enable stopping in case of machine failure.

- Perforated steel tandem walkways and convenient grab rails provide a sturdy platform when moving on, off and around the machine.

- Standard Circle Drive Slip Clutch protects the standard drawbar, circle and moldboard from shock loads if the blade encounters an immovable object and also reduces the possibility of abrupt directional changes in poor traction conditions. The optional Blade Lift Accumulators help absorb impact loads by allowing vertical blade travel. This optional feature reduces wear and impact loading for enhanced operator safety.

Technology

Using the data from technology-equipped machines, get more information and insight into equipment and operations.

Cat Grade Attachment Ready Option (ARO) is the building block for all Cat Motor Grader technologies.

Equipment Management Technology.

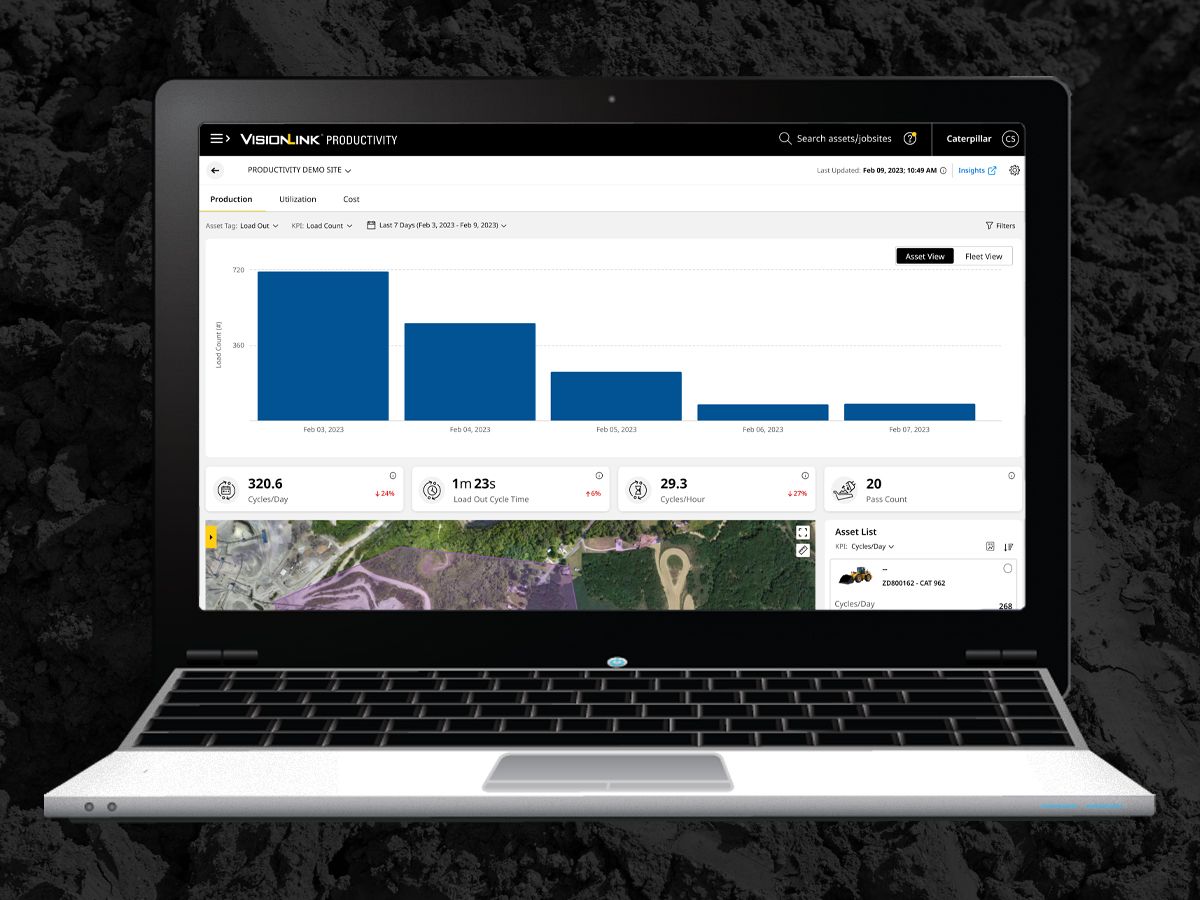

- VisionLink™ provides actionable data insights for all assets - regardless of fleet size or equipment manufacturer.* Review equipment data from your desktop or mobile device to maximize uptime and optimize assets. Dashboards provide information such as hours, miles, location, idle time, and fuel utilization. Make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

- VisionLink™ Productivity gathers and summarizes machine telematics and jobsite data from all your equipment regardless of the manufacture.* View actionable information such as idle time, fuel burn, location, payload, load counts, total cycles, and more to improve machine efficiency, productivity, and utilization. Access data anywhere via a mobile, tablet, or desktop device - on or off the jobsite.

- Cat® Inspect is a mobile application that allows you to easily perform digital Preventative Maintenance (PM) checks, inspections, and daily walkarounds. Inspections can easily be integrated with other Cat data systems like VisionLink so you can keep a close eye on your fleet.

- Cat® Remote Troubleshoot is a mobile application that allows your Cat dealer to perform diagnostic testing on your connected machine remotely to help ensure that issues are resolved quickly and with less downtime.

- Cat Grade 3D

Cat Grade with 3D for motor graders, also called "mastless," is a machine integrated grade control system that helps you get to grade faster with more accuracy, efficiency, and productivity. Automatic blade control reduces operator inputs and the number of passes to get the job done to save you time and money. - Cross Slope Assist

Optional Cross Slope Assist now includes Position Sensing Shift Cylinder (PSC) and two sensors to simplify mastless upgrades. It allows the operator to manually control one end of the moldboard while the system controls the other. - Attachment Ready Option

ARO provides sensor-ready swivel mountings for faster aftermarket work tool installation.

Lower Maintenance Costs

- Grouped filters and access points help operators.

- Engage Eco mode to reduce fuel burn.

- Filters, such as hydraulic oil, engine air, and DEF filters, are grouped together for easy access and preventative maintenance. The next generation filters help reduce your fluid and filter costs.

- Spend less time cleaning the cooling system with the reversing fan option, which helps keep costs down when cleaned once per week giving you more uptime.

- Optional High Performance Circle helps eliminate hours of monthly planned maintenance for frequent inspection, wear strip replacement and circle shoe adjustment associated with conventional circles. Advantages include increased circle torque, performance, and improved durability. It provides a smooth, effortless rotation of blade and assists in meeting road design elevation tolerance.

- Maintain roads with the standard drawbar circle moldboard with hardened circle teeth for increased durability. For tight finish grading, consider the top adjust drawbar option for applications that require maximum accuracy, and offers up to 45 percent reduction in maintenance cost over the standard.

Sustainability

- The Cat engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Engine Idle Shutdown Timer reduces fuel burn, greenhouse gas emissions and unnecessary idle time by shutting down the machine after a pre-set idling period.

- Cat® Grade helps reduce fuel burn and greenhouse gas emissions by enabling you to achieve grade faster and more accurately by automating blade actions.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine.

- VisionLink® displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

- Don't waste fuel idling. Cat VisionLink online fleet monitoring helps you manage idle time and reduce fuel burn and greenhouse gas emissions.

- Cat® Reman parts are a sustainable choice. New Cat parts are designed with the potential to have more than one life, so Cat Reman parts are truly remanufactured — not just repaired, rebuilt or reconditioned. Because the process ensures the latest design changes are incorporated into Cat Reman parts, you get like new quality and outstanding performance at lower cost.

- Standard Equipment

- Optional Equipment

- Specs

- Docs

Standard Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- OPERATOR ENVIRONMENT

- Adjustable steering wheel/lever controls

- Seat belt

- Electric throttle control

- Fully redesigned cab with sound suppression and integrated Roll Over Protective Structure (ROPS) and Falling Object Protection System (FOPS)

- Full color ten-inch (254 mm) liquid crystal touch screen display

- Added storage areas

- Information display screen

- Entertainment radio ready

- Cup holder

- Cell phone holder

- Dome interior light

- Coat hook

- Front wipers

- SAFETY

- Back-up alarm

- Grab rails

- Hydraulic brakes

- Hydraulic system - integrated dead engine implement lower

- Hydraulic system - integrated work port pressure relief

- Parking brake

- Rearview mirror

- Side view mirrors

- Signaling/warning horn

- POWERTRAIN

- Cat C7.1 diesel engine

- Eco mode

- On-demand fan

- 43° C (109° F) standard capacity

- DRAWBAR CIRCLE MOLDBOARD

- Standard drawbar circle moldboard

- Circle drive slip clutch

- ELECTRICAL

- Sealed alternator

- Reversing lights

- Breaker panel

- 900 CCA standard duty batteries

- Electric starter

- Rear lights with LED lighting

- Halogen lighting

- SERVICE AND MAINTENANCE

- Ground Level DEF and Fuel Fill

- Grouped location for engine oil and fuel filters

- Extended life coolant

- Next Generation Filters for Fuel and Engine Oil

- GUARDS

- Transmission

Optional Equipment

- OPERATOR ENVIRONMENT

- Lower front wipers

- Mechanical suspension seat

- Heated / cooled air suspension seat

- Heating/cooling cab system

- Defrost fans

- Rear wiper

- Cab plus

- Rear window screen

- Digital blade slope meter

- Product Link

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- SAFETY

- Four-point safety harness seat belt

- Operator Presence System

- Rearview camera

- Secondary steering system

- Walkways

- Warning beacon

- POWERTRAIN

- Heavy duty starter

- Transmission with Autoshift

- DRAWBAR CIRCLE MOLDBOARD

- Top Adjust Drawbar

- High Performance Circle

- Circle drive slip clutch

- Circle saver

- Remote Pinion Lube

- 4.9 m (16 foot) Moldboard

- ELECTRICAL

- 145A Brushed Alternator

- 1,400 CCA heavy duty batteries

- SERVICE AND MAINTENANCE

- Fast fuel fill ready

- Underhood Lighting

- GUARDS

- Fender

- Cover, under cab platform

- Steering Cylinder Guards

- VERSATILITY

- Towing hitch

- L3 tires

- Sy-Klone pre-cleaner

- ATTACHMENTS AVAILABLE FROM FACTORY

- Lift Groups

- High Performance Circle

- Counterweight

- Push block

- Mid-Machine Scarifier (MMS)

- Rear Ripper/Scarifier

- Moldboards

- Front Blade

- ATTACHMENTS

- Lift Groups

- High Performance Circle

- Counterweight

- Push block

- Mid-Machine Scarifier (MMS)

- Rear Ripper/Scarifier

- Moldboards

- Front Blade

- Snow Wings

- V-Plow

- Straight Plow

- Brooms

Specs

Overview

Long Name:

140 Motor Grader

Name:

140 LVR

Brand:

Cat

Status:

Current

Engine

Net Power - ISO 9249/SAE J1349

248 hp / 174 kW

Engine Model

Cat® C7.1

Bore

4.1 in / 105 mm

Number of Cylinders

6

Weights

Operating Weight - Typically Equipped

42542.6 lb / 19297 kg

Operating Weight - Typically Equipped - Front Axle

11783.7 lb / 5345 kg

Operating Weight - Typically Equipped - Rear Axle

30758.9 lb / 13952 kg

Machine Weight

Lever/Steering Wheel Weight* Tier 4

42167.8 lb / 19127 kg

Lever/Steering Wheel All-Wheel drive (AWD) Weight* Tier 4

43278.9 lb / 19631 kg

Note (1)

* Typically equipped operating weight is calculated with full fuel tank, coolant, lubricants, operator, push block, transmission guard, rear ripper/scarifier, 14.0R24 tires on multi-piece rims, and other equipment.

Moldboard

Blade Width

14 ft / 4267 mm

Power Train

Forward/Reverse Gears

9 Forward / 6 Reverse

Transmission

Powershift Countershaft Transmission

Brakes - Service

Dual Circuit Hydraulic

Brakes - Secondary

Dual Circuit Hydraulic

Brakes - Parking

Spring Applied Hydraulic Release

Hydraulic System

Circuit Type

Parallel

Pump Type

Variable Piston

Note

*Pump output measured at 2000 RPM rated speed

Dimensions

Height - Top of Cab

136 in / 3454 mm

Height - Front Axle Center

24.1 in / 612 mm

Height - Top of Cylinders

119.8 in / 3044 mm

Height - Exhaust Stack

130.4 in / 3313 mm

Length - Push Plate to Ripper

405.4 in / 10297 mm

Length - Front Tire to Rear of Machine

350.8 in / 8911 mm

Length - Between Tandem Axles

59 in / 1498 mm

Width - Tire Center Lines

82.2 in / 2087 mm

Ground Clearance - Rear Axle

13.1 in / 333 mm

Note

All dimensions are approximate and apply to 140 lever Non-AWD and AWD configurations unless otherwise noted.

Standards

Steering

ISO 3449:2005, Level II

Brakes

ISO 3450:2011; AIS-143:2018

Sound

ISO 6396: ISO 6395

Air Conditioning System

Note

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a or R1234yf. See the label or instruction manual for identification of the gas.

- If equipped with R134a (Global Warming Potential = 1430), the system contains 1.6 kg (3.5 lb) of refrigerant which has a CO2 equivalent of 2.288 metric tonnes (2.521 tons).

SEE HOW 140 LVR COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

Motor Graders

140 LVR

- Brand

- Cat

- Status

- Current

- Engine Model

- Cat® C7.1

- Bore

- 4.1 in / 105 mm

- Number of Cylinders

- 6

- Operating Weight - Typically Equipped

- 42542.6 lb / 19297 kg

- Blade Width

- 14 ft / 4267 mm

Selected Model

Motor Graders

140 / 140 AWD LVR

- Brand

- Cat

- Status

- Current

- Engine Model

- Cat C9.3

- Bore

- 4.5 in / 115 mm

- Number of Cylinders

- 6

- Operating Weight - Typically Equipped

- 44613 lb / 20236 kg

- Blade Width

- 12 ft / 3.7 m

Motor Graders

150 / 150 AWD JOY

- Brand

- Cat

- Status

- Current

- Engine Model

- Cat® C9.3

- Bore

- 4.5 in / 115 mm

- Number of Cylinders

- 6

- Operating Weight - Typically Equipped

- 43950 lb / 19935 kg

- Blade Width

- 12 ft / 3.7 m