HM912 Mulcher

HM912 Mulcher

DESCRIPTION

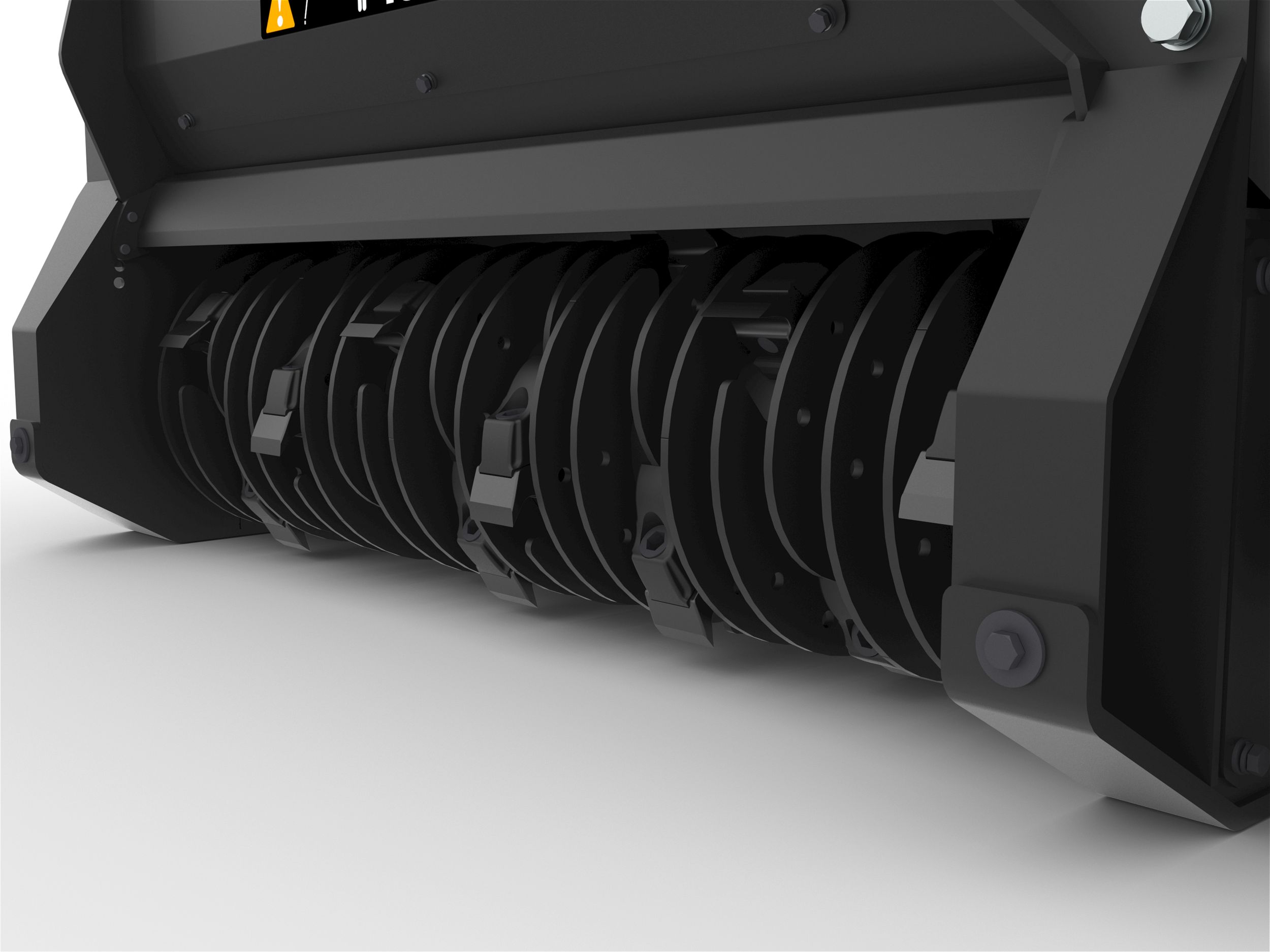

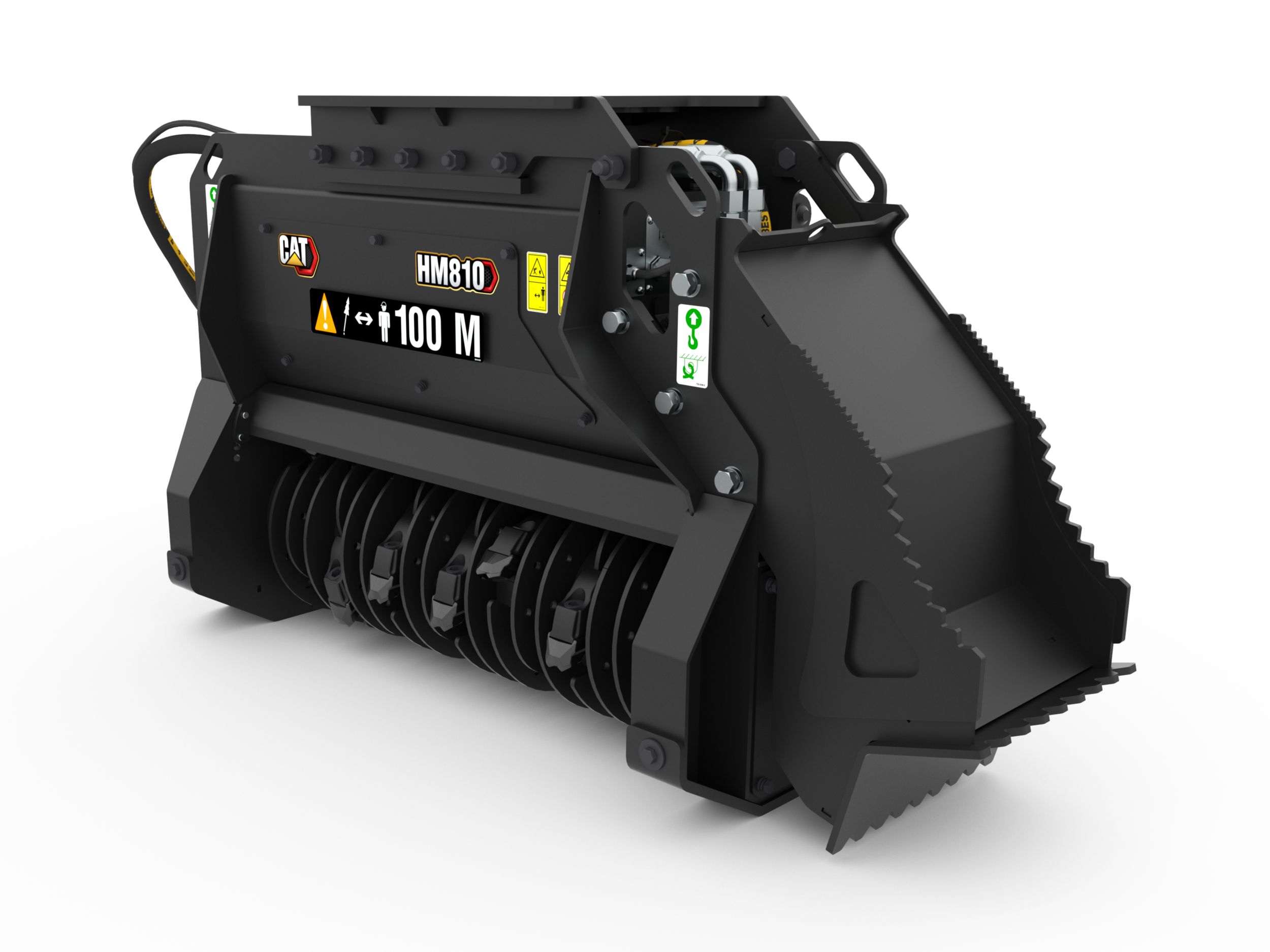

High-performance cutting and mulching of vegetation and overgrowth.Cat® Mulchers for Mini Excavators are designed for high-performance cutting and mulching vegetation and undergrowth from forested terrain. The hydraulic mulcher reduces saplings, shrubs and trees into mulched material, making it ideal for environmental maintenance, such as creating fire lanes. Other applications include land reclamation, foliage removal from building construction sites, and shredding pruned material and organic waste for biomass production.Bite Limiting Plates

Ribs on the rotor limit the amount of material being processed at once to reduce stalls and recovery time.

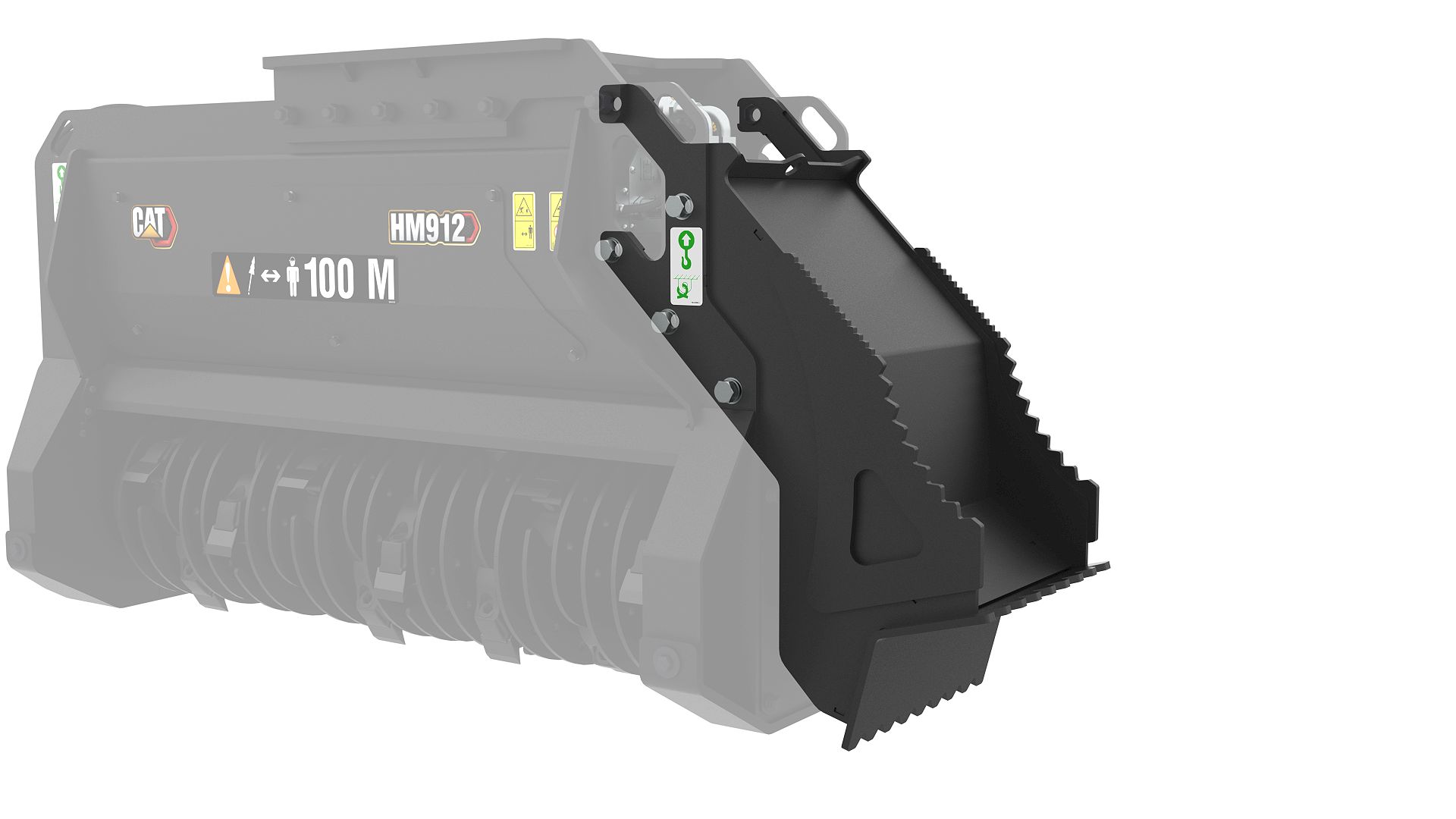

Built in Thumb Bracket

Integrated thumb bracket allows operator to pull or push the material into position to mulch or move it away from the mulching area. On equipped Cat® excavators, the machine thumb can be utilized with the integrated thumb bracket to pick up material.

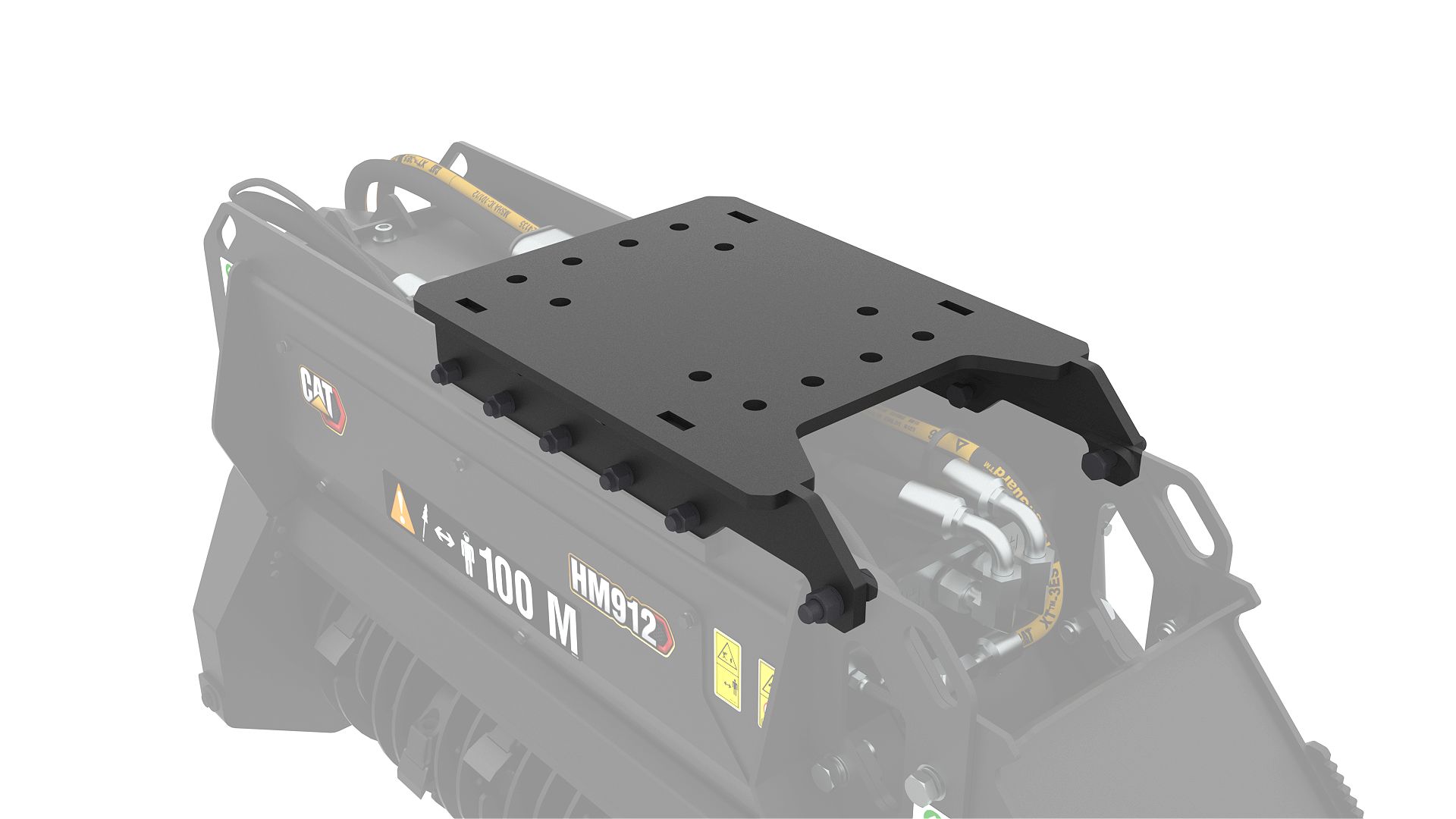

Standardized Mounting Bracket

All bite-limiter mulchers will use the small-large bolt pattern that is common with hammers, vibratory plate compactors, cold planers, and grapples. Mounting brackets are available in these bolt patterns to fit the full range of compatible Cat® machines and coupler styles.

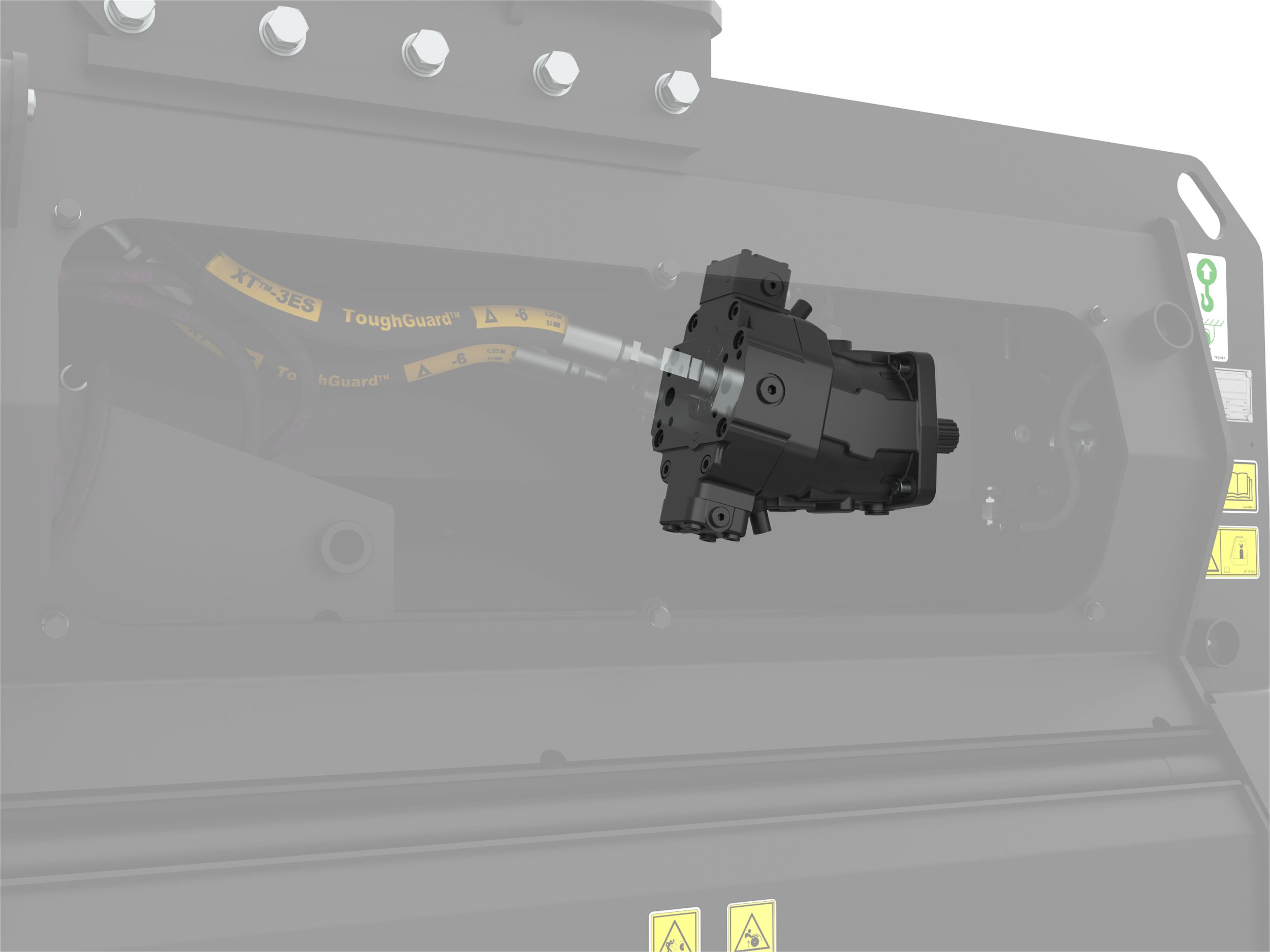

Variable Torque Hydraulic Motor

Variable displacement piston motor provides for excellent multi-function capability of machine platform. Motor displacement will change to provide high torque at low speed to power through material with reduced risk of stalling. The motor automatically switches the displacement back for high speed operation once the material is cleared.

Bolt-on Replaceable Skid Shoes

Bolt-on skid shoes are reinforced and built to last, but easily replaceable as needed. Provides differentiation longevity over the competition, which generally has welded on skids.

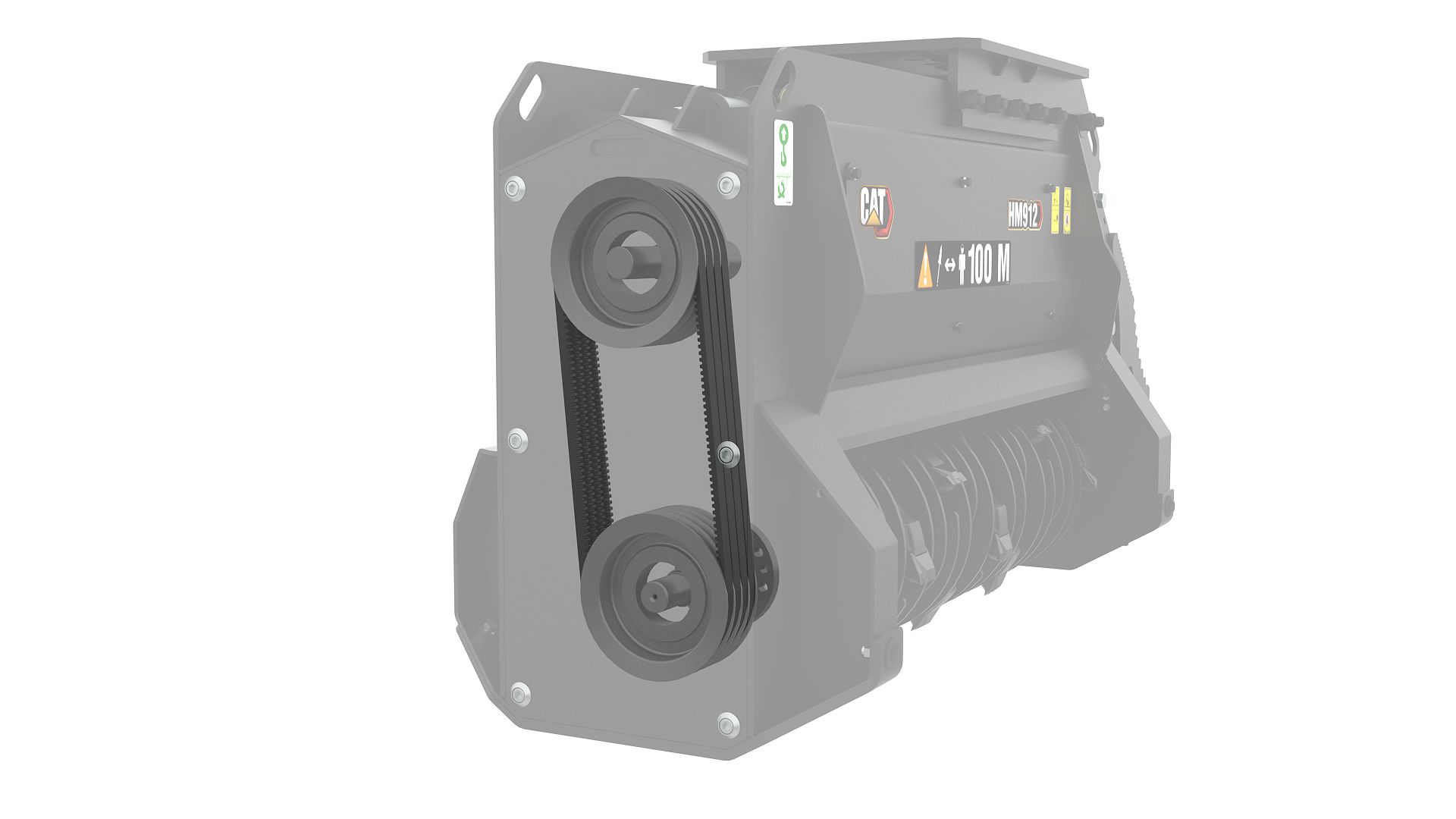

V-Belt Drive

Multi V-belt design enables the transmission of torques between the hydraulic motor and the cutting head.

Hydraulic Hood (HM810 and HM912 only)

The HM810 and HM912 models have a hydraulic-actuated door that allows the operator to control material discharge and finish of the product.

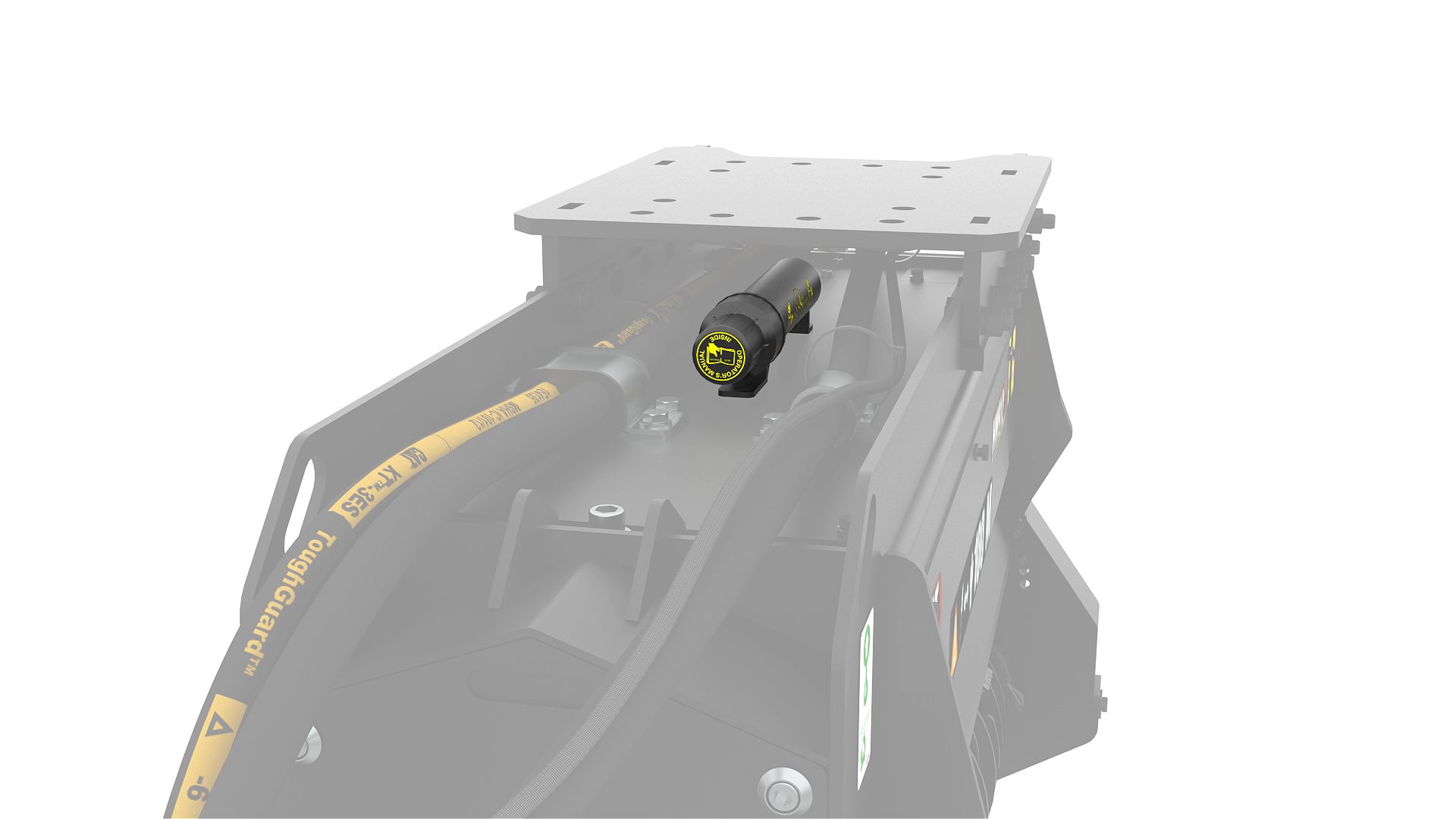

OMM Tube

Stores the OMM (Operation and Maintenance Manual) in a protective case on the attachment, where it can be conveniently accessed. The tooth sharpening gauge can also be stored in the OMM container.

- Specs

Specs

Overview

SEE HOW HM912 Mulcher COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Cat

- Status

- Current

- Overall Width

- 71.1 in / 1806 mm

- Working Width

- 47.2 in / 1200 mm

- Length

- 28.1 in / 713 mm

- Overall Height

- 35.5 in / 901 mm

- Weight

- 1653.5 lb / 750 kg

- Drive Method

- V-Belt

- Motor

- Dual Speed Axial Piston Motor

- Required Hydraulics

- 1st Auxiliary

- Optimal Hydraulic Flow

- 100-140 l/min (26.4-37 gpm)

- Optimal Hydraulic Pressure

- 150-250 bar (2175-3626 psi)

- Drum Speed

- 2931 RPM

- Fixed Teeth per Drum

- 22

- Maximum Cutting Diameter

- 6 in / 152 mm

- Brand

- Cat

- Status

- Current

- Overall Width

- 61.7 in / 1566 mm

- Working Width

- 37.8 in / 960 mm

- Length

- 28.1 in / 713 mm

- Overall Height

- 35.5 in / 901 mm

- Weight

- 1512.4 lb / 686 kg

- Drive Method

- V-Belt

- Motor

- Dual Speed Axial Piston Motor

- Required Hydraulics

- 1st Auxiliary

- Optimal Hydraulic Flow

- 95-131 l/min (25.1-34.6 gpm)

- Optimal Hydraulic Pressure

- 150-250 bar (2175-3626 psi)

- Drum Speed

- 2767 RPM

- Fixed Teeth per Drum

- 18

- Maximum Cutting Diameter

- 6 in / 152 mm

- Brand

- Cat

- Status

- Current

- Overall Width

- 54.6 in / 1388 mm

- Working Width

- 31.3 in / 794 mm

- Length

- 21.9 in / 555 mm

- Overall Height

- 30.7 in / 779 mm

- Weight

- 1104.5 lb / 501 kg

- Drive Method

- V-Belt

- Motor

- Dual Speed Axial Piston Motor

- Required Hydraulics

- 1st Auxiliary

- Optimal Hydraulic Flow

- 70-90 l/min (18.5-23.8 gpm)

- Optimal Hydraulic Pressure

- 150-250 bar (2175-3626 psi)

- Drum Speed

- 2749 RPM

- Fixed Teeth per Drum

- 14

- Maximum Cutting Diameter

- 5 in / 127 mm