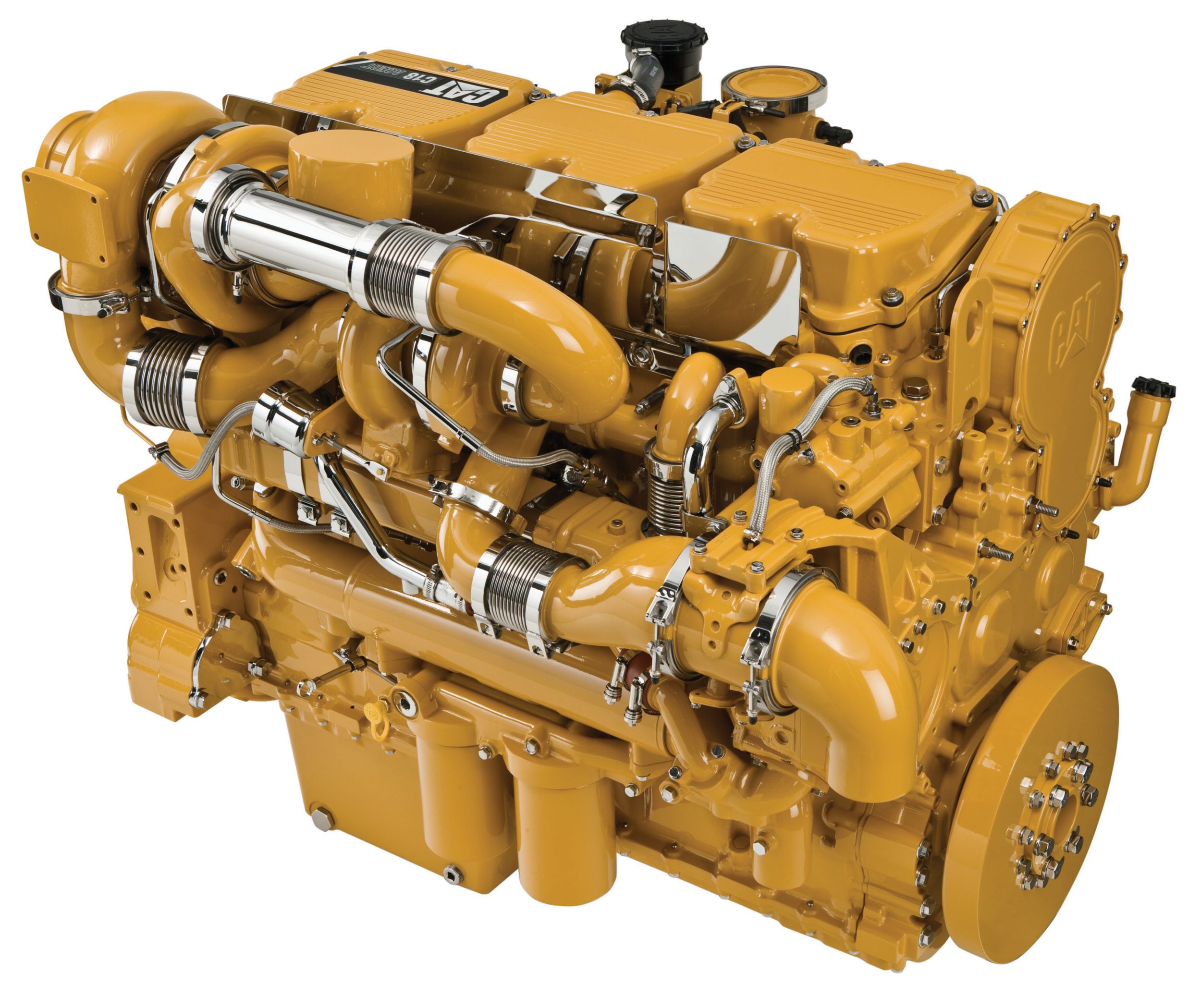

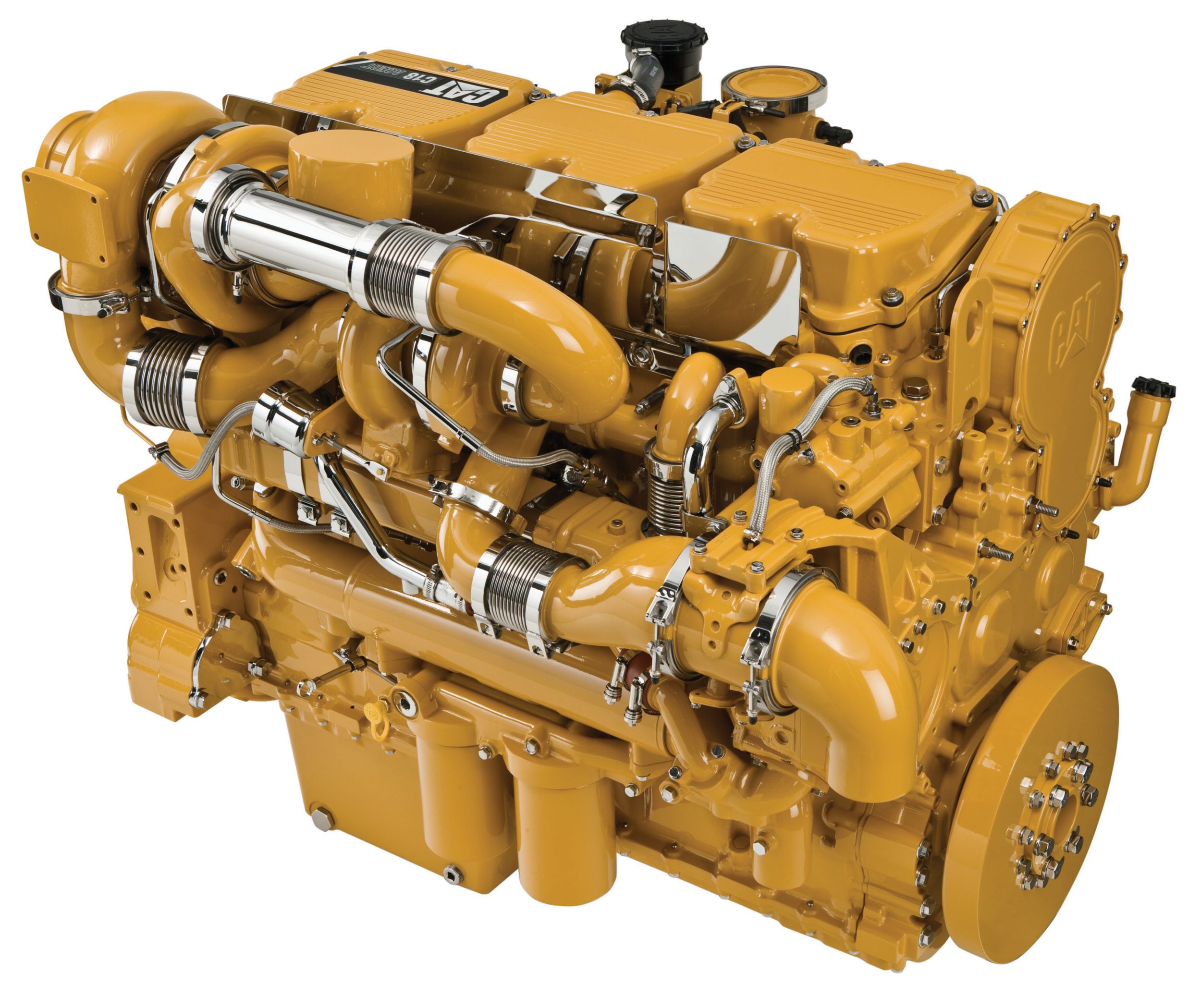

An exceptional, globally recognized product line. A knowledgeable, experienced team. Unparalleled customer service.

These are just a few reasons why Hawthorne Cat is the best choice for your business in San Diego County, the Hawaiian Islands, Guam, American Samoa, and Saipan.

LEARN MORE »