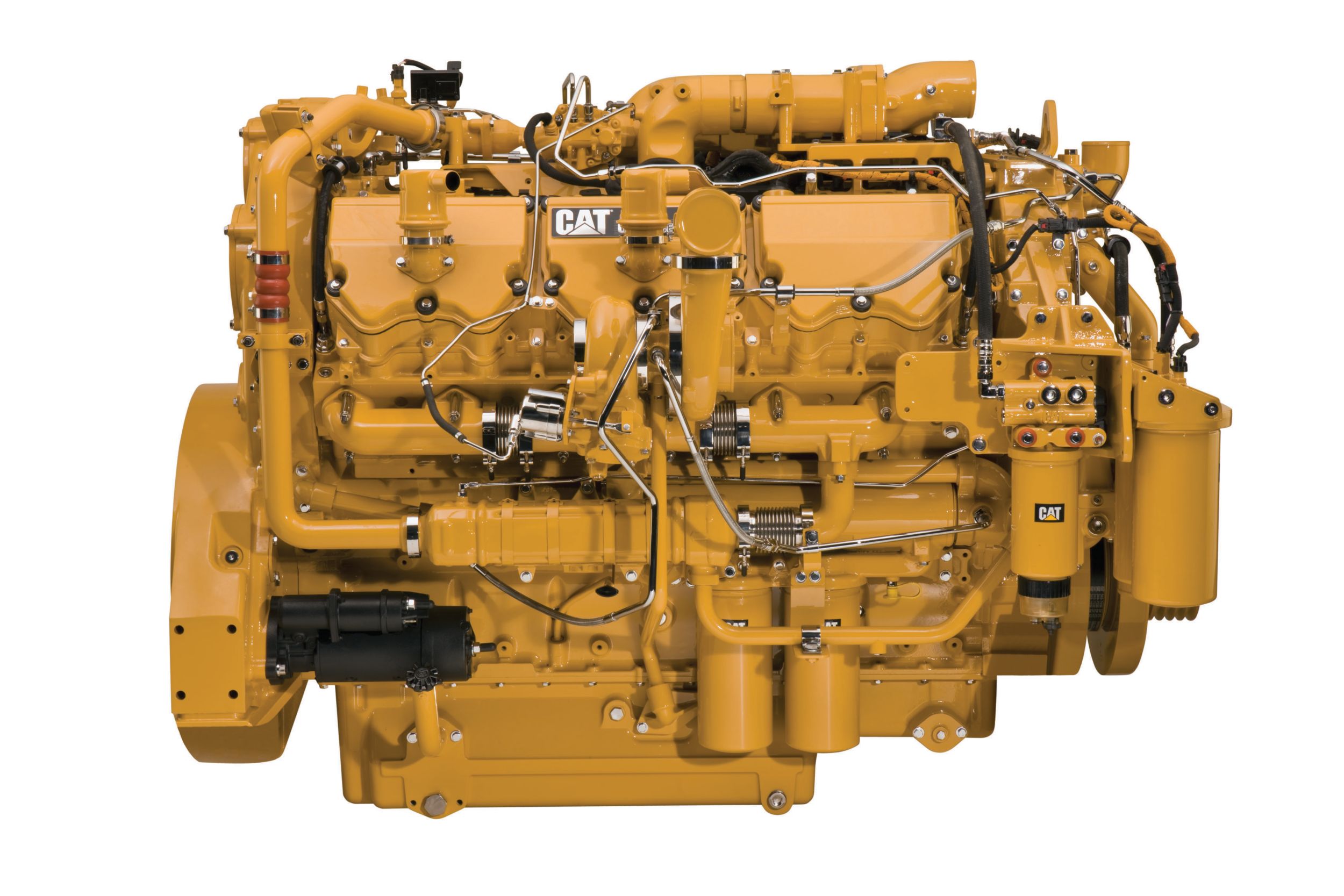

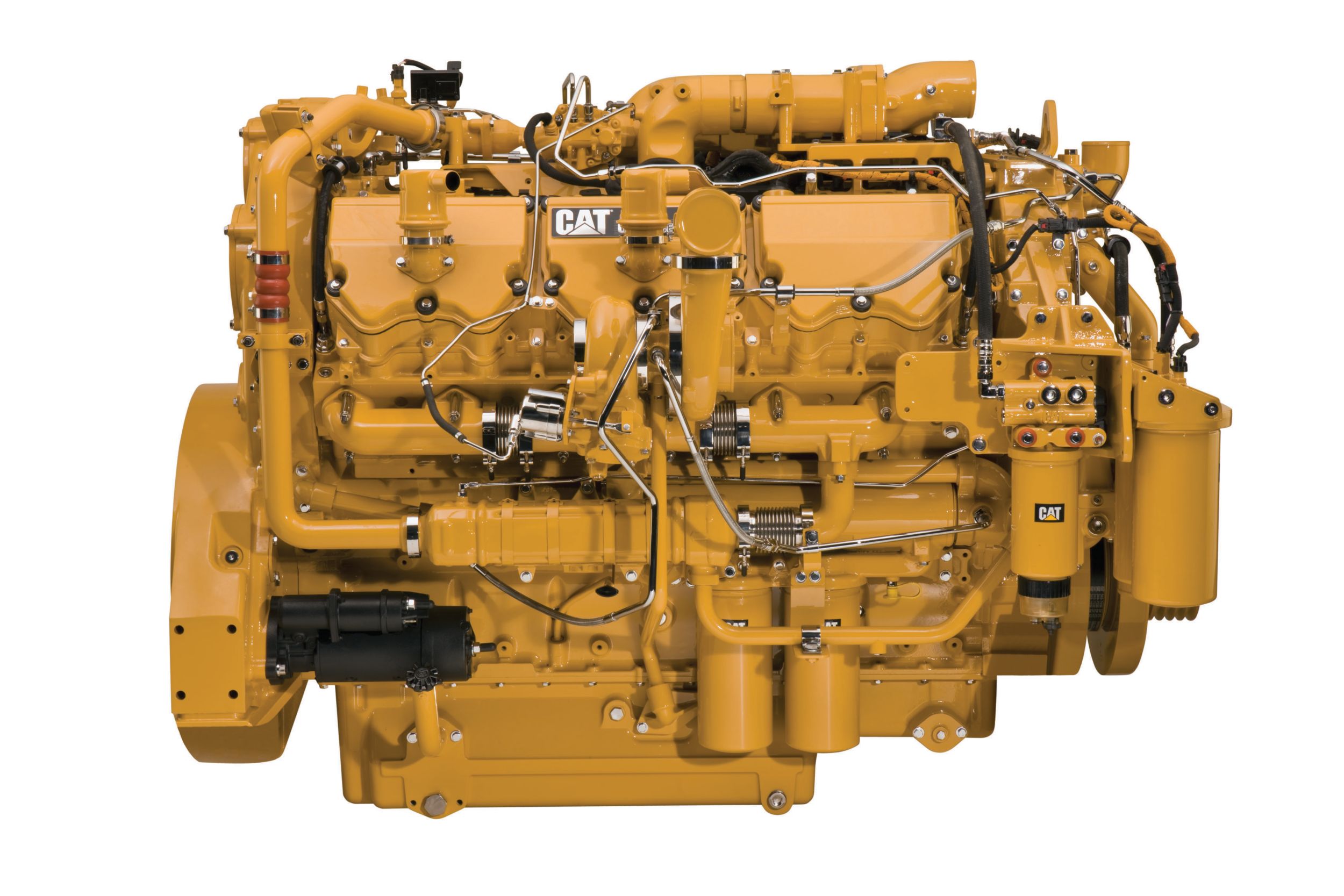

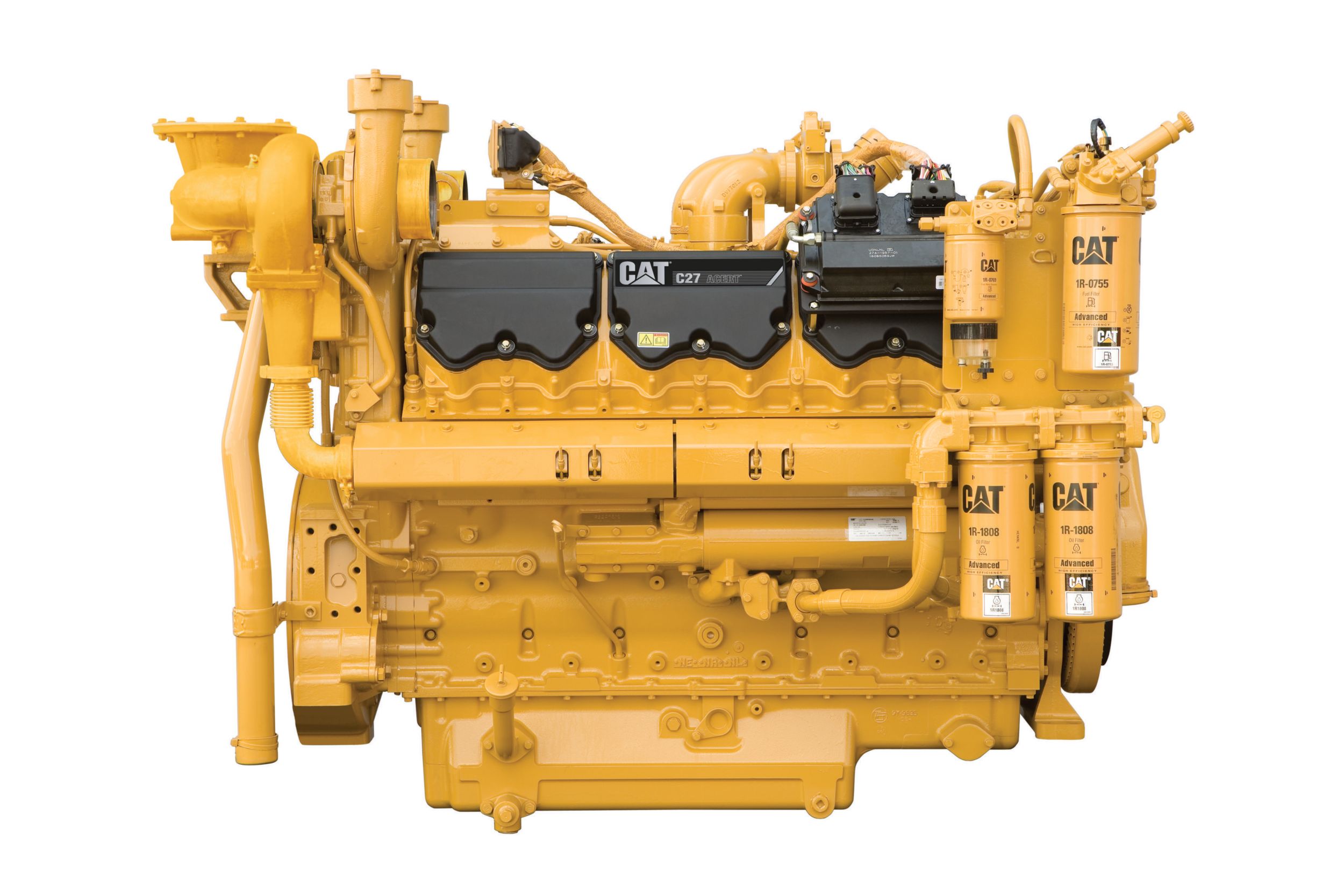

C27 ACERT™

C27 ACERT Tier 4 Final

DESCRIPTION

Cat C27 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C27 ACERT engines to deliver excellent performance with low operating costs while meeting the tightest environmental requirements.This is an ideal engine for applications that require Tier 4 Final emissions certifications in land mechanical drilling equipment such as mud pumps.Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty.Cat C27 ACERT Diesel Engine. Ratings: 597-708 bkW (800-950 bhp) @ 1800 rpm are designed to meet U.S. EPA Tier 4 Final emission standards.Cat C27 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C27 ACERT engines to deliver excellent performance with low operating costs while meeting the tightest environmental requirements.This is an ideal engine for applications that require Tier 4 Final emissions certifications in land mechanical drilling equipment such as mud pumps.Cat C27 ACERT™ Industrial Diesel Engine. Ratings: 597-708 bkW (800-950 bhp) @ 1800 rpm are designed to meet U.S. EPA Tier 4 Final emission standards.Oil and GasEmissions

- Designed to meet U.S. EPA Tier 4 Final emissions requirements. - On-engine NOx reduction system with optimized piston, ring, liner, and fuel system configuration to reduce NOx while minimizing in-cylinder sooting- Aftertreatment features diesel oxidation catalyst- Meets Tier 4 Final emissions requirements four years early, achieving environmental benefits earlier than required.

Engine Design

- Proven reliability and durability of engine and aftertreatment- Broad operating speed range- High power density- PTO drive options provide flexible access to auxiliary power for pumps and other needs

Low Total Cost of Ownership

- Optimized fuel consumption- Maintenance-free aftertreatment

Advanced Digital Engine Management

ADEM A4 control system providing integrated ignition, speed governing, protection, and controls, including detonation-sensitive variable ignition timing. ADEM A4 has improved: user interface, display system, shutdown controls, and system diagnostics.

Custom Packaging

For any petroleum application, trust Caterpillar to meet your exact needs with a factory custom package. Cat® engines, generators, enclosures, controls, radiators, transmissions, aftertreatment solutions — anything your project requires — can be custom designed and matched to create a one-of-a kind solution. Custom packages are globally supported and are covered by a one-year warranty after startup.

Transmissions

- Caterpillar has a full line of engine-transmission packages that can be fully integrated with your axle, hydraulics, and operator interface.- Please contact Application Support Center for details.

Testing

Every engine is full-load tested to ensure proper engine performance

Product Support Offered Through Global Cat Dealer

- More than 2,200 dealer outlets- Caterpillar factory-trained dealer technicians service every aspect of your petroleum engine- Caterpillar parts and labor warranty- Preventive maintenance agreements available for repairbefore-failure options- S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine:- Internal engine component condition- Presence of unwanted fluids- Presence of combustion by-products- Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.- Cast engine blocks, heads, cylinder liners, and flywheel housings- Machine critical components- Assemble complete engine

Web Site

For all your petroleum power requirements, visit www.catoilandgasinfo.com.

- Standard Equipment

- Specs

- Docs

Standard Equipment

- Air Inlet System

- Twin rear-mounted turbochargers, ATAAC

- Control System

- Automatic altitude compensation; power compensation for fuel temperature; electronic diagnostics and fault logging; engine monitoring and protection system (speeds, temperature, pressure); J1939 Broadcast (diagnostic, engine status and control); ADEM A4 electronic control

- Cooling System

- Thermostats and housing; jacket water pump, geardriven, centrifugal, RH

- Exhaust System

- Exhaust dry manifold, 127 mm (5 in) slip fit connection, diesel oxidation catalyst

- Fuel System

- Mechanical Electronic Unit Injection (MEUI™) system; primary, secondary, and tertiary fuel filter; electronic fuel priming pump-integrated with primary fuel filter base; fuel transfer pump

- Lube System

- Remote-mounted oil filters and RH-side blockmounted filters are available; crankcase fumes disposal system, RH mounted; oil cooler — RH; oil filler — RH; oil level gauge — RH; shallow rear sump oil pan — 250-hour

Specs

Overview

Engine Specifications

Capacity for Liquids

Dimensions

SEE HOW C27 ACERT™ COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Caterpillar

- Status

- Current

- Maximum Rating

- 950 BHP / 708 bkW

- Emissions

- U.S. EPA Non-road Tier 4 Final

- Displacement

- 1648 in³ / 27 l

- Minimum Rating

- 800 BHP / 597 bkW

- Bore

- 5.4 in / 137.7 mm

- Stroke

- 6 in / 152.4 mm

- Rated Speed

- 1800 r/min / 1800 r/min

- Aspiration

- Turbocharged-Aftercooled

- Governor and Protection

- ADEM A4

- Engine Weight - Net Dry

- 6151 lb / 2790 kg

- Oil Change Interval

- 250

- Rotation from Flywheel End

- Counterclockwise

- Flywheel and Flywheel Housing

- SAE No. 0

- Flywheel Teeth

- 136

- Minimum Cooling System - Engine Only

- 15.9 gal (US) / 60 l

- Length

- 85 in / 2159 mm

- Width

- 49 in / 1253 mm

- Height

- 63 in / 1594 mm

- Brand

- Caterpillar

- Status

- Current

- Maximum Rating

- 1150 BHP / 858 bkW

- Emissions

- U.S. EPA Non-road Tier 2

- Displacement

- 1658 in³ / 27.2 l

- Minimum Rating

- 800 BHP / 597 bkW

- Bore

- 5.4 in / 137.7 mm

- Stroke

- 6 in / 152.4 mm

- Rated Speed

- 2100 r/min / 1800 r/min

- Aspiration

- Turbocharged-Aftercooled

- Governor and Protection

- ADEM A3

- Engine Weight - Net Dry

- 6382 lb / 2895 kg

- Oil Change Interval

- 250

- Rotation from Flywheel End

- Counterclockwise

- Flywheel and Flywheel Housing

- SAE No. 0 or SAE No. 1

- Flywheel Teeth

- 136 (SAE 0), 113 (SAE 1)

- Minimum Cooling System - Engine Only

- 14.5 gal (US) / 54.9 l

- Length

- 75.5 in / 1918 mm

- Width

- 57.6 in / 1463 mm

- Height

- 52 in / 1321 mm

- Brand

- Caterpillar

- Status

- Current

- Maximum Rating

- 1125 BHP / 839 bkW

- Emissions

- U.S. EPA Non-road Tier 4 Final

- Displacement

- 1958 in³ / 32.1 l

- Minimum Rating

- 1125 BHP / 839 bkW

- Bore

- 5.7 in / 145 mm

- Stroke

- 6.4 in / 162 mm

- Rated Speed

- 1800 r/min / 1800 r/min

- Aspiration

- Turbocharged-Aftercooled

- Governor and Protection

- ADEM A4

- Engine Weight - Net Dry

- 6107 lb / 2770 kg

- Oil Change Interval

- 250

- Rotation from Flywheel End

- Counterclockwise

- Flywheel and Flywheel Housing

- SAE No. 0

- Flywheel Teeth

- 136

- Minimum Cooling System - Engine Only

- 15.9 gal (US) / 60 l

- Length

- 85 in / 2159 mm

- Width

- 49 in / 1253 mm

- Height

- 63 in / 1594 mm