Cat D6 Dozer

The New Cat D6 Dozer | Supreme Fuel Efficient Cat Dozer

Staying on time and on budget has never been easier with the all-new Cat® D6 Dozer, delivering improved levels of work efficiency with top-of-the-line grading performance. The redesigned, purpose-built VPAT dozer’s updated technology features, wide variety of attachment options, and choice of Electric Drive or Fully Automatic power train make the D6 dozer one of the most productive machines Cat has ever built. The all-new cab and range of configuration choices make it a machine for all of your future worksites.

Power Train Options to Best Fit Your Business

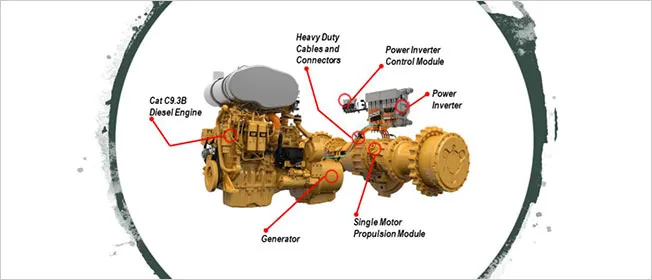

The next-generation D6 dozer offers two advanced power train options: the D6 XE with Electric Drive or the D6 with a fully automatic, 4-speed power shift transmission.

The D6 XE is the world’s first high drive, Electric Drive dozer offering up to 35% better fuel efficiency than other dozers of its class. Continuous power to the ground and push, plus greater maneuverability make cycle times faster for maximum productivity. The simplified diagnostics and serviceability advantages help reduce needed service and maintenance costs. The enhanced productivity, and reduced fuel and maintenance costs mean that customers can see payback on the added investment over a D6 in less than two years.*

The D6 fully automatic, 4-speed power shift transmission dozer offers up to 20% better fuel efficiency versus 3-speed counterparts by reducing momentary hesitation when shifting to maintain momentum and power during the entire push. The auto shift functionality is designed to work up and down the entire working range of the machine for optimized fuel consumption and power, a greater percentage of the time. An added gear between first and second enhances shifting for a more seamless experience.

Both the D6 and D6 XE dozers offer Cat’s best ever ease of operation. Operators only need to set the ground speed and the dozer continuously optimizes itself for maximum power based on the load. Electric drive ensures there are no gears to shift, and the fully automatic 4-speed power train optimizes the transmission when shifting, giving you peace of mind no matter your machine preference.

Cat’s Fastest Grading Option

Finish jobs faster by grading at higher speeds with the purpose-built Variable Power Angle Tilt (VPAT) dozer. The structure is stronger and lighter to best optimize the machine for grading without the need of a rear implement or counterweight. The wide gauge LGP VPAT design, with 36” centered shoes, puts more track on the ground during operation to achieve 5 psi (0.73 kPa) ground pressure.

The D6’s wider VPAT blade and range of motion improve performance for all of your projects, especially when trenching and backfilling. A new optional grading undercarriage includes 10 bottom rollers for smoother grade at increased speeds, even in challenging, uneven surfaces like sand or gravel.

Technology for Every Application

Cat Connect GRADE technologies increase the D6 and D6 XE’s overall jobsite productivity up to 50%, ranging from standard Slope Indicators to full factory-integrated GPS, all supported by Hawthorne Cat. All technology offerings for the D6 are led by an updated Cat GRADE with 3D system and new 10-inch touch screen, advanced Inertial Measuring Unit (IMU), smaller antennas, and AutoCarry™ features to make working on the jobsite easier, with all the answers at your fingertips.

Other GRADE technology choices include:

- Cat Slope Indicate

- Cat GRADE with Slope Assist™

- Attachment Ready Option (ARO)

- Product Link™

- VisionLink®

Reduced Service and Maintenance Costs

The D6/D6 XE reduces maintenance and service costs up to 12% with its updated components, increased time between service intervals, and fewer scheduled maintenance tasks. Easily accessed grouped service points and maintenance items, plus a new ladder in the back of the machine, reduce routine maintenance and inspection times.

Updates to the undercarriage are also designed to extend the life of your machine. A new Heavy Duty Extended Life undercarriage features Positive Rin Rentention pins and link improvements for up to 20% more seal life in high impact conditions. Plus, common structures for Heavy Duty and SystemOne™ undercarriages enable changes from one to the other.

In addition to these updates, a new Cat 9.3B diesel engine has a redesigned fuel system that provides greater durability and more accurate fuel delivery. Elimination of the NOx Reduction System and a simplified single engine Electronic Control Module (ECM) help increase reliability.

Prioritized Cab Comfort

The D6 cab has been completely redesigned in order to raise the standard of comfort and productivity of the operator. In addition to the 10-inch touchscreen display, the standard air suspension seat is wider with added backward adjustment, the entire armrest adjusts independent of the seat, heated/cooled leather seat options are available, and a variety of seat adjustments including cushion length, head rest position, lumbar support, and seat tilt, all help the dozer feel custom tailored to the operator’s specific needs.

Distributed cab heating/cooling features with automatic temperature and blower control, circulate the air more effectively around the operator during operation and less air directed toward the windows helps reduce fogging/frosting. Integrated ROPS and 15% more overall glass area help increase visibility while working improving efficiency on the jobsite.

Equipped for Any Job

The D6/D6 XE dozers wide range of features including advanced power train, Cat Connect GRADE technologies, and custom operator adjustments make it one of the most advanced machines Cat has ever built. A variety of blade types, track shoe widths, rear attachments, and more are also available to optimize your dozer for all types of primary work to keep your business up and running for years to come.

*Productivity = BCM (BCY)/hour, fuel consumption = L (gal)/hour. Estimates based on average cost per bank cubic meters (cubic yards) of material moved in typical construction applications with 1,500 hours/year. Individual results may vary based on application, hour utilization, operator and other factors.

WAIPAHU SERVICE

MACHINERY SERVICE

Doug Kaauwai

Oahu Product Support Operations Manager

[email protected]