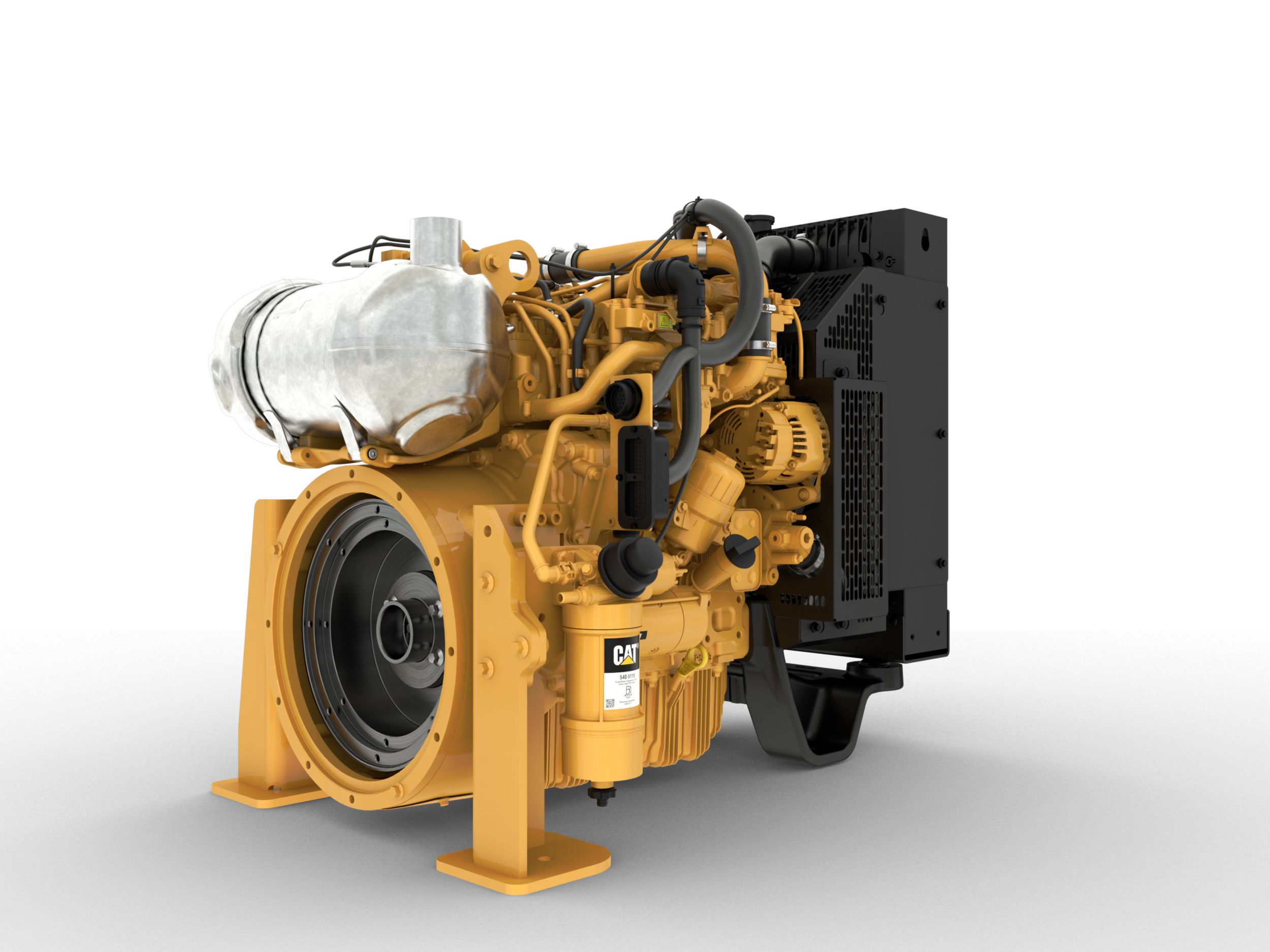

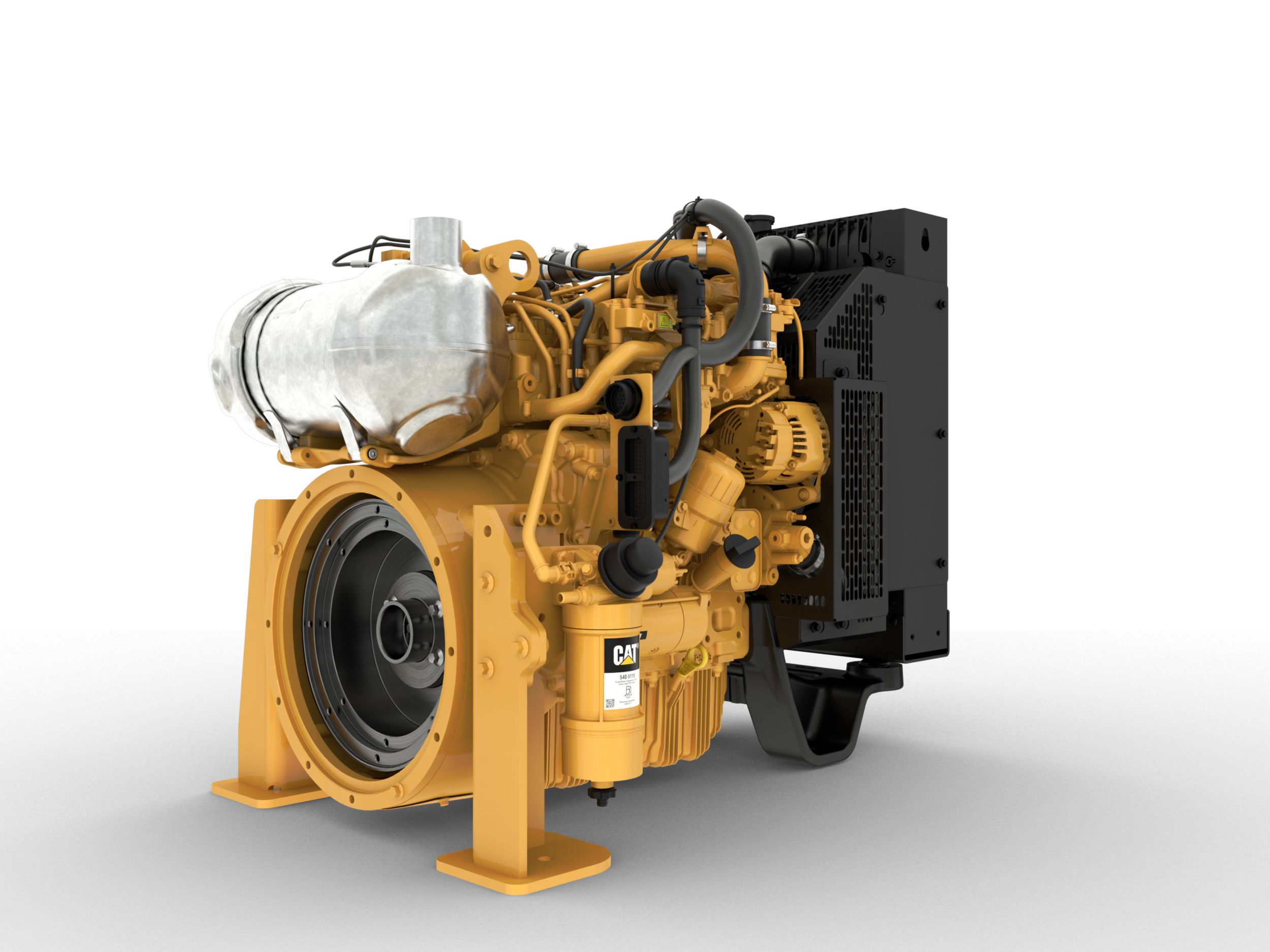

C2.8

Cat?� C2.8 Industrial Power Unit

DESCRIPTION

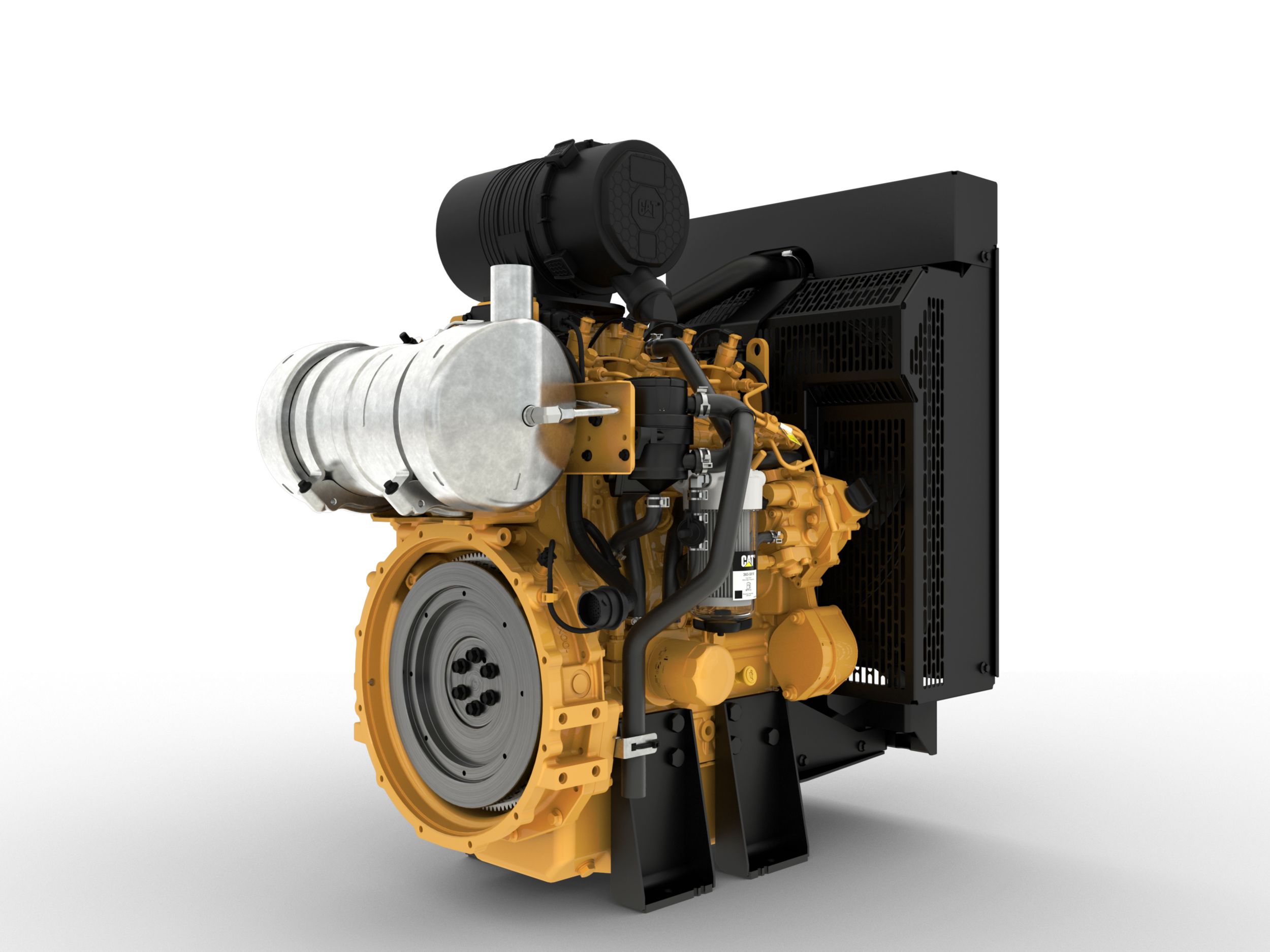

The C2.8 and C3.6 IPU engines are common rail direct injection engines with a turbocharged or turbocharged aftercooled air system meeting EU Stage V, U.S. EPA Tier 4 Final and Japan 2014 (Tier 4 Final) emission standards. For ease of installation, the IPU provides full aftertreatment mounting, an integrated cooling system, a full wiring harness and mounting for the ECM and fuel filter.The C2.8 and C3.6 IPU engines are common rail direct injection engines with a turbocharged or turbocharged aftercooled air system meeting EU Stage V, U.S. EPA Tier 4 Final and Japan 2014 (Tier 4 Final) emission standards. For ease of installation, the IPU provides full aftertreatment mounting, an integrated cooling system, a full wiring harness and mounting for the ECM and fuel filter.Designed to meet EU Stage V/U.S. EPA Tier 4 Final/ Japan 2014 (Tier 4 Final) emission standards.Industrial Power

Ready to Go for Machine Installation

The ECM, aftertreatment sensors and fuel filter have all been mounted on the IPU and validated to operate in the harshest of environments.

A bespoke wiring harness has also been developed to allow for a simple hookup to the machine wiring.

For the quickest installation possible, an optional engine control panel for engine monitoring and speed control is also available.

Reliable, Quiet, and Durable Power

World-class manufacturing capability and processes coupled with proven technologies and extensive field validation assure reliability and durability in tough non-road applications

Zero Downtime for Regeneration

Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), and on the C3.6 Selective Catalytic Reduction (SCR) system supplied installed on-engine to provide zero downtime for regeneration

- Standard Equipment

- Specs

- Docs

Standard Equipment

- Aftertreatment Equipment

- Aftertreatment mounted on engine as standard

- Air System

- Standard and heavy duty air cleaners

- Cooling System

- 50:50 water glycol mix

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Engine mounted radiator with top tank temperature of 108°C (226°F)

- Pusher or puller fan options

- Radiator erosion screen is available

- Electrical and Electronics

- 12V system

- Data interface via CANbus J1939

- Instrument control panel available

- Full electronic control

- Glow plugs for best cold starting with minimum battery impact

- High power alternator and starter motor options

- Sensors and robust wiring harness included

- Flywheel and Flywheel Housing

- SAE3 flywheel housing and flywheel with pilot bore

- Wide choice of interfaces for common transmissions and hydraulic pumps

- Fuel System

- Electronic high pressure common rail

- Fuel filter - IOPU mounted

- Standard and heavy duty fuel filtration

- Water sensor included - early warning for operator

- General

- Cold-start capable with standard equipment to -25°C

- Supplied painted or lacquered

- Oil System

- Oil filters - mounting options available on either side of the engine, plus remote

- Dipsticks - choice of position and length

- High incline sump. 35° continuous in all directions. Suitable for machines that are used on steep slopes

- Power Take-Off (PTO)

- SAE-A and SAE-B interfaces available

Specs

Overview

Power Rating

Emission Standards

General

Engine Dimensions*

Disclaimer

SEE HOW C2.8 COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Caterpillar

- Status

- Current

- Maximum Power

- 74 hp / 55 kW

- Maximum Torque

- 221 lb-ft @ 1600 rpm / 300 Nm @ 1600 rpm

- Rated Speed

- 2200-2400 rpm

- Minimum Power

- 74 hp / 55 kW

- Emissions

- EU Stage V/U.S. EPA Tier 4 Final/ Japan 2014 (Tier 4 Final)

- Bore

- 3.54 in / 90 mm

- Stroke

- 4.33 in / 110 mm

- Displacement

- 170.9 in³ / 2.8 l

- Compression Ratio

- 17.0:1

- Aspiration

- Turbocharged

- Rotation from Flywheel End

- Anti-clockwise

- Aftertreatment

- DOC+DPF

- Brand

- Caterpillar

- Status

- Current

- Maximum Power

- 74 hp / 55 kW

- Maximum Torque

- 199 lb-ft @ 1600 rpm / 270 Nm @ 1600 rpm

- Rated Speed

- 2800 rpm

- Minimum Power

- 49 hp / 36.4 kW

- Emissions

- EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 (Tier 4 Final)

- Bore

- 3.3 in / 84 mm

- Stroke

- 3.9 in / 100 mm

- Displacement

- 135 in³ / 2.2 l

- Compression Ratio

- 17.0:1

- Aspiration

- Turbocharged or Turbocharged Aftercooled

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- DOC+DPF

- Brand

- Caterpillar

- Status

- Current

- Maximum Power

- 950 hp / 709 kW

- Maximum Torque

- 3211 lb-ft @ 1200 rpm / 4354 Nm @ 1200 rpm

- Rated Speed

- 1800 rpm

- Minimum Power

- 800 hp / 597 kW

- Emissions

- U.S. EPA Tier 4 Final, EU Stage V

- Bore

- 5.7 in / 137.2 mm

- Stroke

- 6 in / 152.4 mm

- Displacement

- 1649.5 in³ / 27 l

- Compression Ratio

- 16.0:1

- Aspiration

- Twin Turbocharged-Aftercooled (TTA)

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- DOC