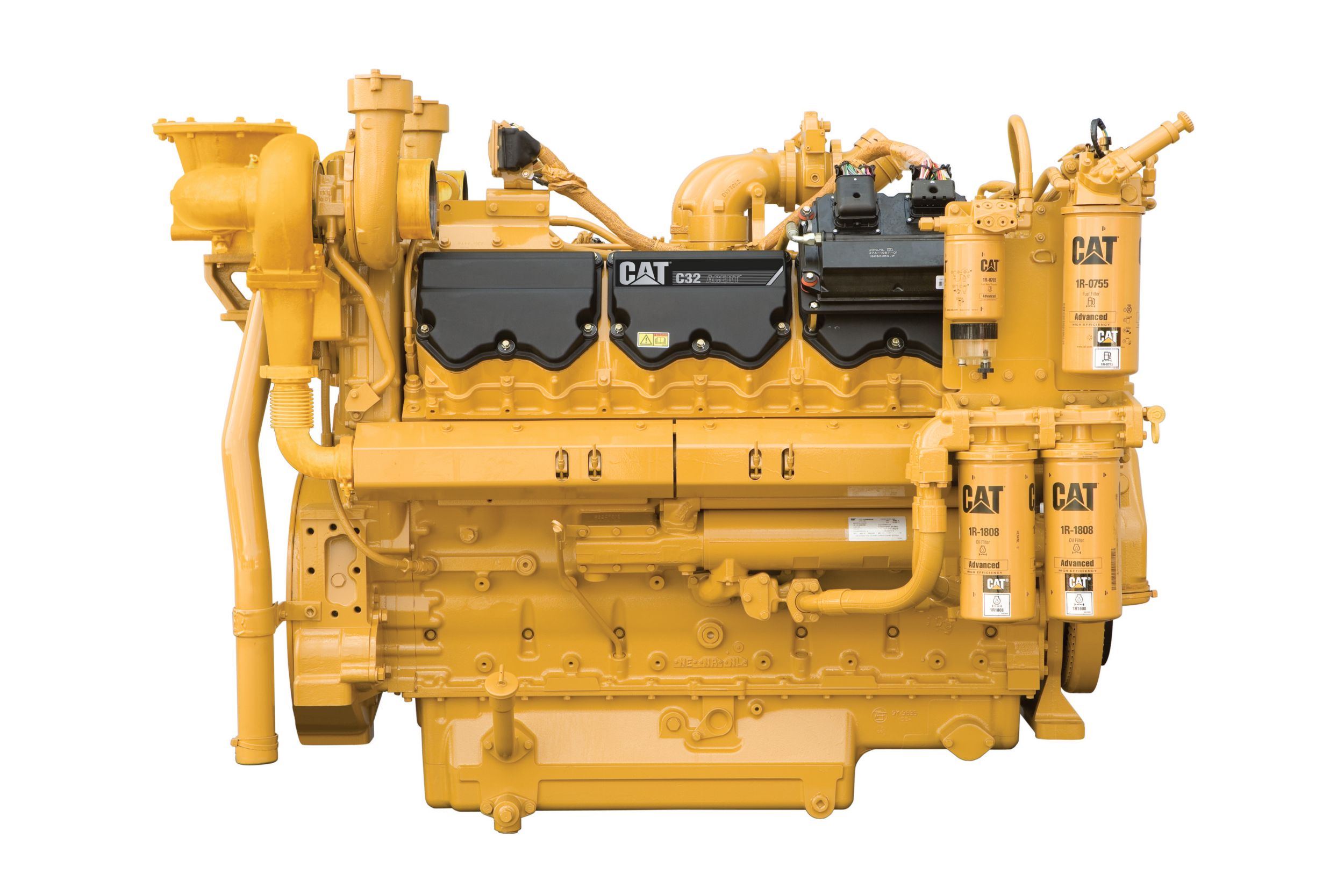

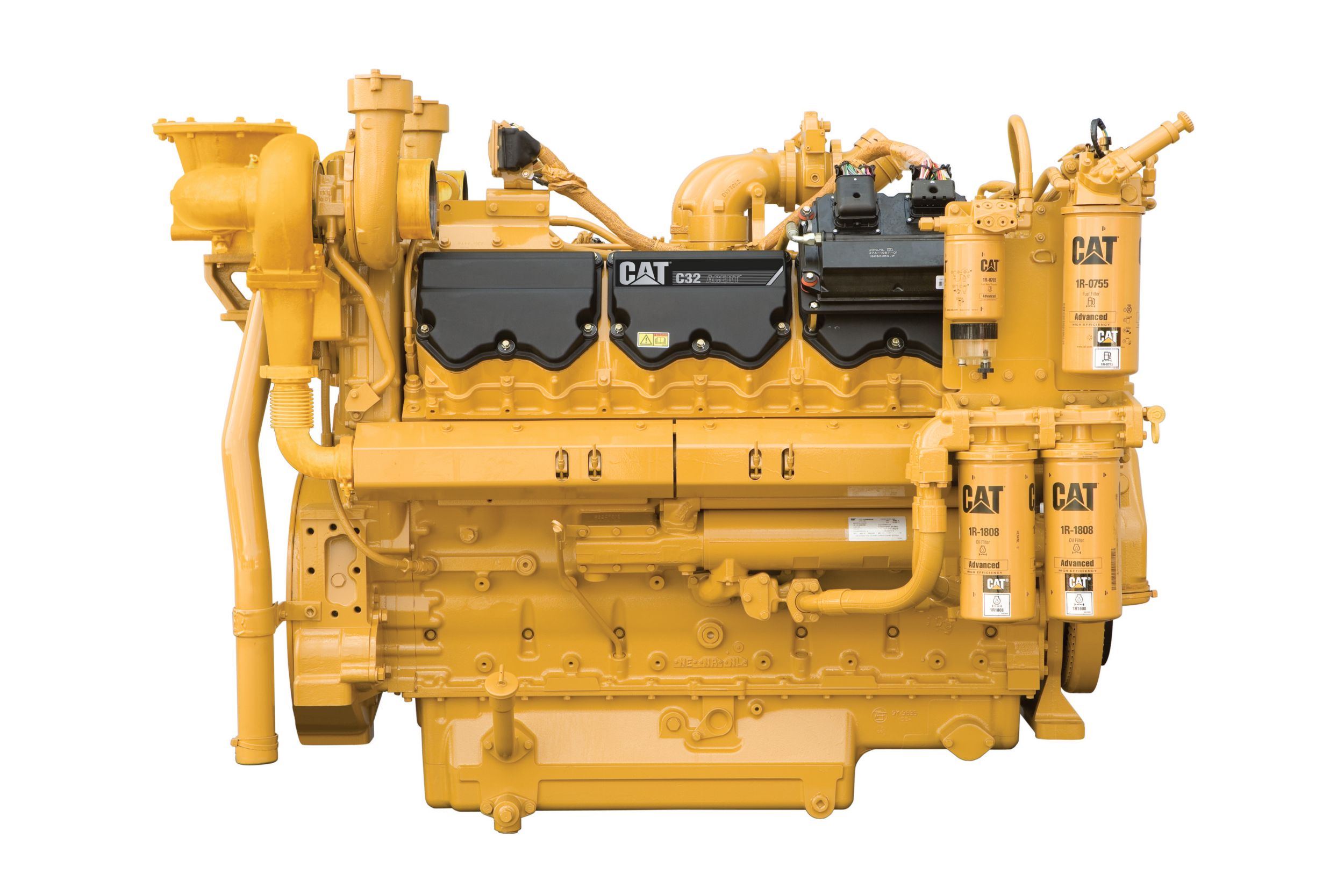

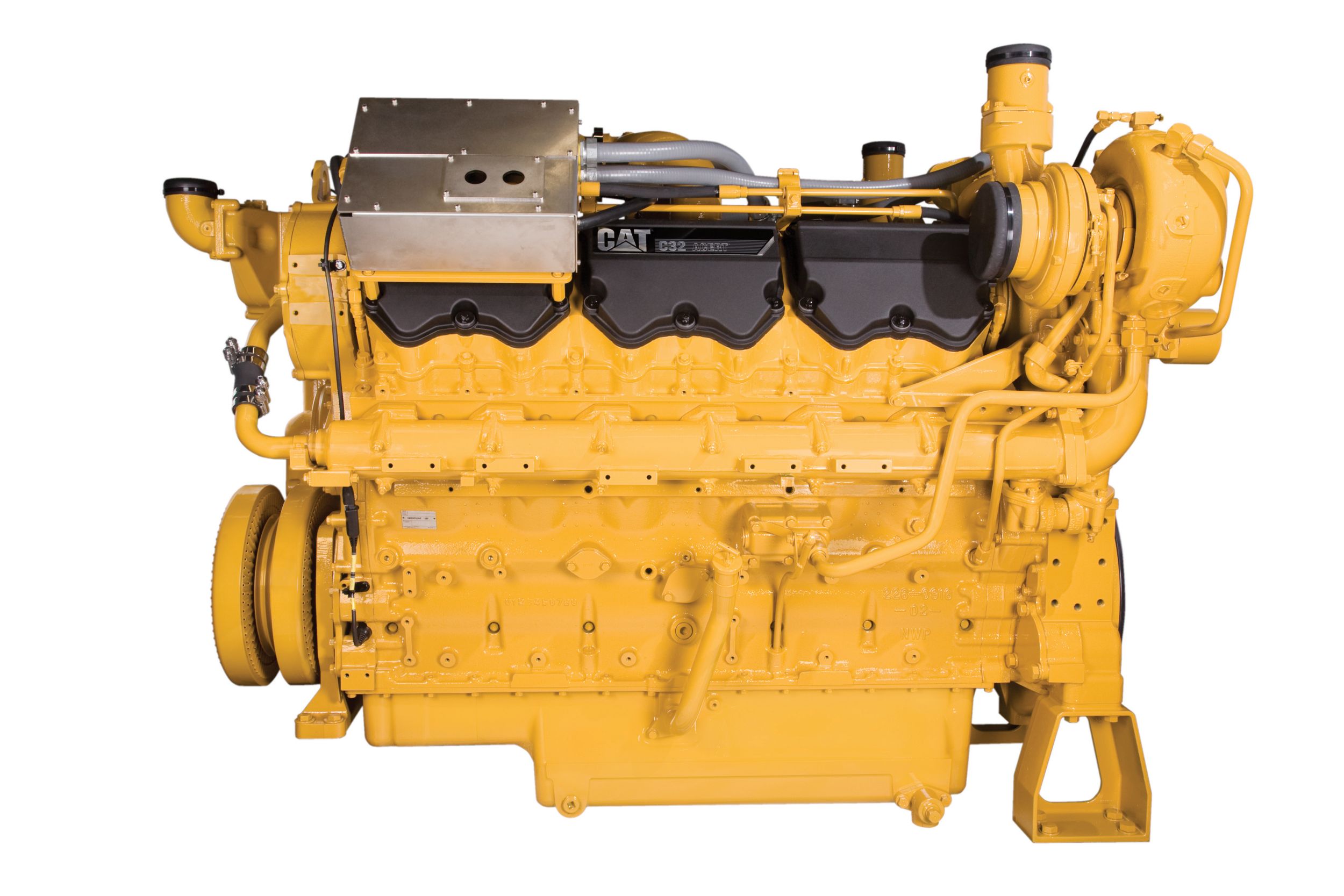

C32 ACERT™ (Dry Manifold)

C32 ACERT™ Dry Manifold Engine

DESCRIPTION

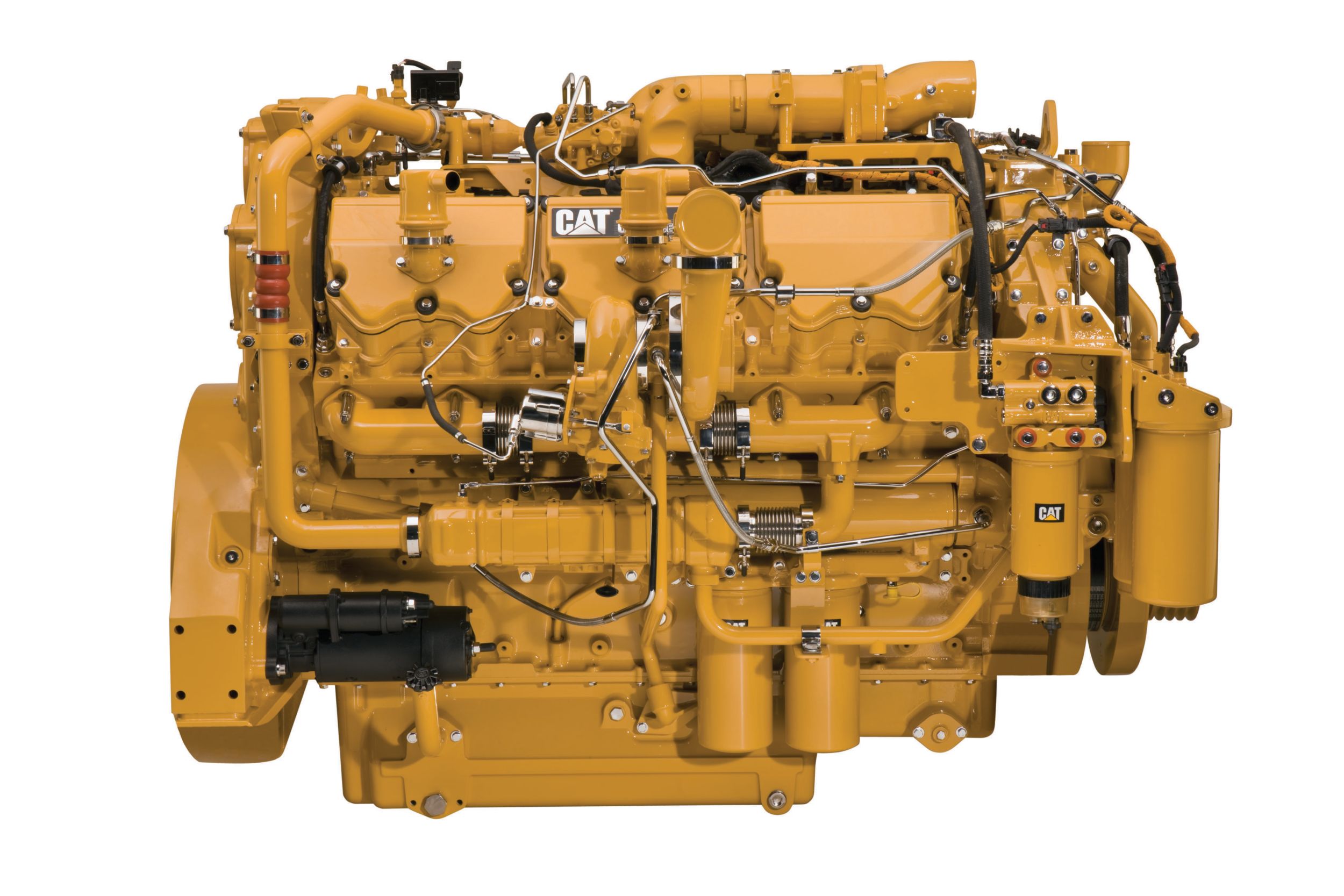

Cat C32 ACERT engines are the ideal solution for your demanding operations in the oilfield. Decades of field operation and intense research and development allow Cat C32 ACERT engines to deliver excellent performance with low operating costs and emissions. Equipment powered by C32 ACERT engines include well stimulation pumping, pump skids, nitrogen units, acidizing units, blenders, and hydraulic power units. Cat engines are backed by the worldwide network of Cat dealers ready to support your operation with technical support, service, parts, and warranty. Cat C32 ACERT Industrial Diesel Engine. Ratings: 597-1119 bkW (800-1500 bhp) @ 1800-2100 rpm meet U.S. EPA Tier 2 equivalent and China Stage III emission standards. They are available using U.S. EPA Flexibility, and for other regulated and non-regulated areas.Custom Packaging

For any petroleum application, trust Caterpillar to meet your project needs with custom factory generator sets and mechanical packages. Cat engines, generators, controls, radiators, and transmissions can be custom designed and matched in collaboration with our local dealers to create unique solutions. Custom packages are globally supported and are covered by a one year warranty after startup.

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time

Testing

Every engine is full-load tested to ensure proper engine performance.

Product Support Offered Through Global Cat Dealer

More than 2,200 dealer outlets Cat factory-trained dealer technicians service every aspect of your petroleum engine Cat parts and labor warranty Preventive maintenance agreements available for repairbefore-failure options S•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine: - Internal engine component condition - Presence of unwanted fluids - Presence of combustion by-products - Site-specific oil change interval

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Over 80 Years of Engine Manufacturing Experience

Ownership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.

Web Site

For all your petroleum power requirements, visit www.cat.com/oilandgas.

- Standard Equipment

- Optional Equipment

- Specs

- Docs

Standard Equipment

- Air Inlet System

- Connections configured for ATAAC (Air-to-Air-Aftercooled) or remote heat exchanger

- Control System

- ADEM A4 electronic control module

- Electronic governing, PTO speed control

- Customer programmable ratings

- Cold mode start strategy

- Automatic altitude compensation

- Automatic fuel temperature compensation

- Programmable low and high idle, and top engine speed limit

- Electronic diagnostics and fault logging

- Engine monitoring system

- SAE J1939 broadcast (diagnostic and engine status)

- Cooling System

- Gear-driven centrifugal jacket water pump — RH

- Integrated thermostat and housing

- Engine oil cooler

- Optional installed transmission oil cooler

- Exhaust System

- Exhaust manifold — dry

- Two vertical exhaust outlets (front and rear)

- Fuel System

- MEUI

- Fuel priming pump

- Fuel transfer pump

- Primary and secondary fuel filter — RH configured for remote mounting (installed RH on shipping plate)

- Flywheels and Flywheel Housing

- SAE No. 0 or SAE No. 1 flywheel iron housing

- SAE No. 0 or SAE No. 1 flywheel

- Optional transmission adapter

- Lube System

- Crankcase breather

- Oil filter — RH standard, optional LH or remote mount service

- Oil level gauge — RH standard, optional LH or dual service

- Oil filler — RH standard, optional LH or dual service

- Shallow oil pan, rear sump

- Mounting System

- Trunnion front support

- Vertical and horizontal pads on rear flywheel housing

- Protection System

- 24V electronic

- Engine overspeed with optional air shut-offs with indicators

- Low engine oil pressure

- Fuel filter restriction

- Fuel temperature

- High engine coolant temperature

- Low engine coolant temperature

- General

- Vibration damper and optional guard

- Lifting eyes

- Optional customer wiring connector

- Service tool connector

- Paint — Cat yellow

Optional Equipment

- Air Inlet System

- Air cleaner

- Air inlet adapters

- Turbocharger outlet adapters

- Air lines

- Charging System

- Battery chargers

- Charging alternators

- Alternator mounting

- Circuit breakers and mountings

- Cooling System

- Dry charge coolant conditioners

- Thermostat housing

- Coolant level sensor

- Radiator

- Blower fans

- Suction fans

- Fan adapters

- Fan drives

- Emissions

- IMO certifications

- Exhaust System

- Elbows

- Mufflers

- Fuel Systems

- Electric fuel priming pump

- Instrumentation

- Customer management device

- Interconnect harness

- Gauges and instrument panels

- Lube System

- Oil pans

- Oil service side

- Oil level gauge

- Oil filters

- Lubricating oils

- Mounting System

- Structural steel base

- Engine support — front

- Engine support — rear

- Power Take-Offs

- Auxiliary drive

- Damper pulley

- Hydraulics gear pumps

- Protection System

- Mechanical shutoffs

- Solenoid shutoffs

- Starting System

- Electric starting motors - 12V, 24V

- Battery sets - 24V

- Battery cable

- Battery rack

- Starting aids

- Transmission Arrangement

- Transmissions water lines

- Transmissions cooler

Specs

Overview

General Specifications

Emissions

General Specifications

Dimensions

Capacity for Liquids

SEE HOW C32 ACERT™ (Dry Manifold) COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

- Brand

- Caterpillar

- Status

- Current

- Maximum Rating

- 1007 BHP / 1350 bkW

- Emissions

- EPA and CARB Non-Road Mobile Tier 2, IMO Tier II, China Stage III

- Displacement

- 1960.5 in³ / 32.1 l

- Aspiration

- Turbocharged - Aftercooled

- Flywheel and Flywheel Housing

- SAE No. 0 or SAE No. 1

- Flywheel Teeth

- 136

- Stroke

- 6.4 in / 162 mm

- Bore

- 5.7 in / 145 mm

- Length

- 76.18 in / 1934.9 mm

- Width

- 56.34 in / 1431 mm

- Height

- 54.66 in / 1388.3 mm

- Weight

- 5040 lb / 2286 kg

- Brand

- Caterpillar

- Status

- Current

- Maximum Rating

- 950 BHP / 708 bkW

- Emissions

- U.S. EPA Tier 4 Final

- Displacement

- 1648 in³ / 27 l

- Aspiration

- Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

- SAE No. 0

- Flywheel Teeth

- 136

- Stroke

- 6 in / 152.4 mm

- Bore

- 5.4 in / 137.7 mm

- Length

- 85 in / 2159 mm

- Width

- 49 in / 1253 mm

- Height

- 63 in / 1594 mm

- Weight

- 6151 lb / 2790 kg

- Brand

- Caterpillar

- Status

- Current

- Maximum Rating

- 1110 BHP / 828 bkW

- Emissions

- U.S. Non-Road Tier 2 CARB, IMO Tier II, EPA Marine Tier 2

- Displacement

- 1960 in³ / 32.1 l

- Aspiration

- Turbocharged-Aftercooled

- Flywheel and Flywheel Housing

- SAE No. 0 or SAE No. 1

- Flywheel Teeth

- 136

- Stroke

- 6.4 in / 162 mm

- Bore

- 5.7 in / 145 mm

- Length

- 76.18 in / 1934.9 mm

- Width

- 56.34 in / 1431 mm

- Height

- 54.66 in / 1388.3 mm

- Weight

- 6950 lb / 3152 kg