Marine Products

For All of Your Sea Adventures

Providing Top Quality Marine Products Since 1956

Here at Hawthorne Cat, we understand how important our sea-faring industries are. From fishing and recreation to commercial, research, government, and defense needs, we've been providing marine products since 1956. From marine engines to gen sets and power solutions, we've set out to ensure you can serve your customer with available products and services. Our engineering team will help you work through any project utilizing Cat’s entire product line, ensuring a solution that meets or exceeds all your requirements. If you are looking for a comprehensive array of marine products, contact one of our Cat dealers in San Diego, Hawaii, American Samoa, Guam, or Saipan today.

NEW MARINE SALES

After-Treatment Solutions

Cat Certified Marine Dealer

Customer Value Agreements (CVA)

A thorough inspection for wear and tear and uneven distribution

Engine Monitoring & Display Systems

Extended Service Coverage

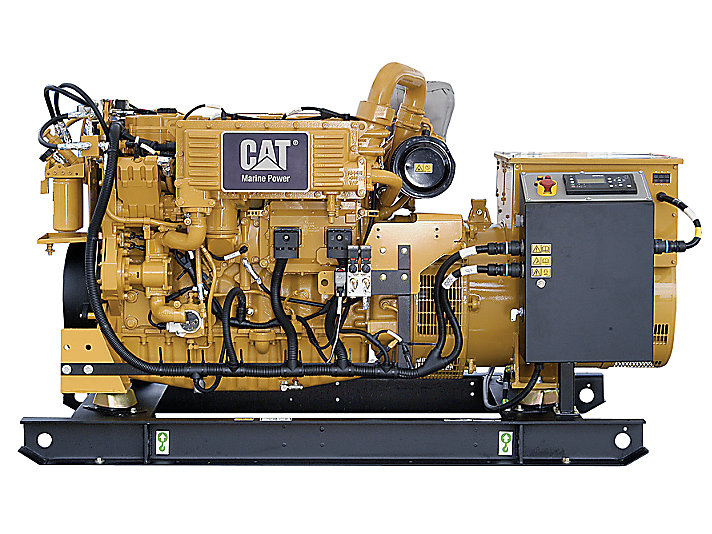

Generator Sets

Integrated Vessel Monitoring, Safety, and Control Systems

Marine Controls

Marine Power Generation

Start-Up/Commissioning

Marine Power Solutions Guide

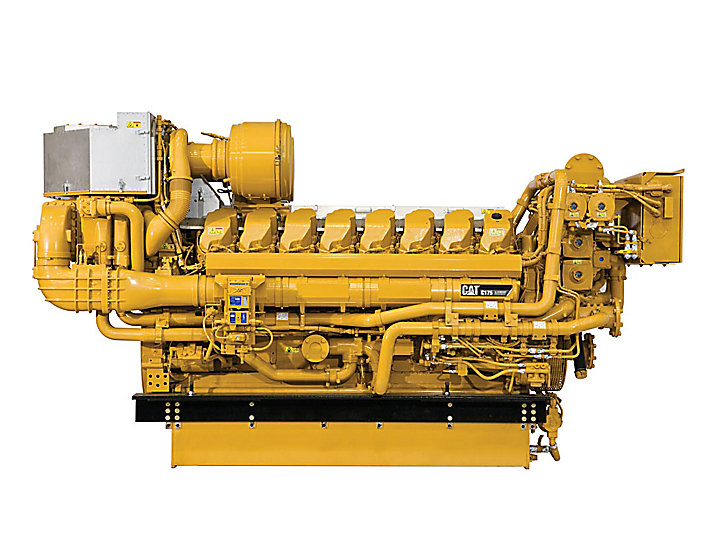

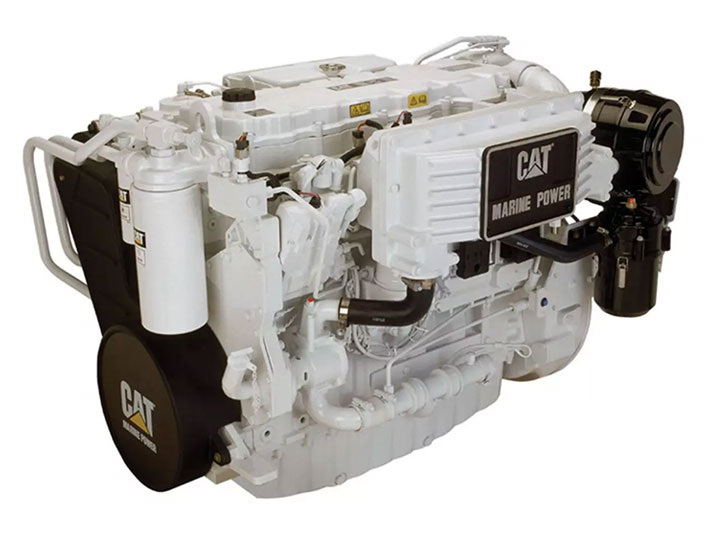

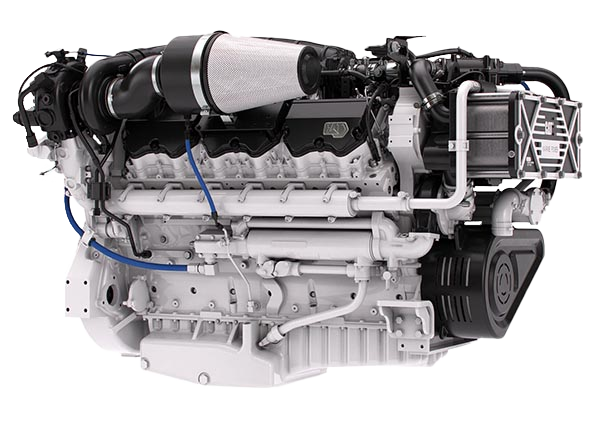

No matter the marine power solution you’re business is looking for, Hawthorne Power Systems has what you need. Cat Marine’s Power Solutions Selections Guide is your go to for all things marine power. This annual publication includes Cat, MaK, and EMD products renowned not only for their reliability, durability, and efficiency, but also for their designs and innovations.

Browse specifications for various models including propulsion and auxiliary engines, generator sets, and more. With this guide you can find the engine type, engine dry weight, water displacement, and more for each unit, as well as current product features.

Current product offerings in the Marine Power Solutions Guide include:

- After treatment solutions

- Complete generator sets

- Complete fuel gas handling systems

- Complete integrated vessel monitoring, safety, and control systems

- Diesel and dual fuel engines as propulsion and auxiliary engines

- Propeller and azimuth propulsion systems to ensure your vessel’s maneuverability and control

WHY CHOOSE OUR MARINE SOLUTIONS

Caterpillar has been in the marine industry for over 80 years. We've been a pioneer in ensuring your water vehicle has everything it needs to keep on running and serving your customers well. Whether you are catching fish for local restaurants or you are defending our nation's waterways, we've got your needs covered. We offer a complete range of conventional and electronic propulsion solutions spanning across commercial and leisure applications. Our marine products are well-known for their reliability, durability, and efficiency. But that's not all. Caterpillar marine products take the case for design performance and manufacturing innovation. In sum, if you are looking for the perfect marine solution, look no further than Hawthorne Cat. Contact one of our Cat dealers in San Diego, Hawaii, American Samoa, Guam, or Saipan today.

CHOOSE HAWTHORNE CAT TODAY

When considering which marine company to choose for all of your marine product needs, you have a lot of options. However, none have the capabilities that Caterpillar offers. With over 100 years of experience and over 500 Caterpillar dealer locations, we are dedicated to your success. By offering a comprehensive service, you don't have to waste time dilly-dallying with other companies. We can help you with your marine products, services, and parts. Our marine Cat engines meet all standards of emissions worldwide. Whether you are looking for recreational or commercial marine needs, you can rest assured you'll keep on moving. Contact one of our dealer locations to get started today!

Marine Industries »

SAN DIEGO - MARINE POWER

Mike Stumpo

Marine Product Support Sales Representative

[email protected]

Amir Mahmoud

Defense Sales Manager

[email protected]

Bryan De Wit

General Service Manager - Power Systems

[email protected]