6060

6060 Hydraulic Mining Shovel

DESCRIPTION

The Cat® 6060 Hydraulic Mining Shovel is the industry’s most popular hydraulic shovel in its size class. And for good reason. With its rated payload of 61 tonnes (67 tons), the Cat 6060 was the first shovel in the mining industry tailor-made for mines using 240-ton (218-tonne) haul trucks, providing an efficient truck-shovel system solution to meet production capacity in these environments. Today's 6060 remains the ideal shovel for these applications, with improvements and enhancements in durability and reliability to deliver the uptime you demand. And its powerful engine and efficient hydraulic system allow higher working speeds for fast cycle times. The result is higher productivity and lower overall owning and operating costs.The Cat® 6060 Hydraulic Mining Shovel is the industry’s most popular hydraulic shovel in its size class. And for good reason. With its rated payload of 61 tonnes (67 tons), the Cat 6060 was the first shovel in the mining industry tailor-made for mines using 240-ton (218-tonne) haul trucks, providing an efficient truck-shovel system solution to meet production capacity in these environments. Today's 6060 remains the ideal shovel for these applications, with improvements and enhancements in durability and reliability to deliver the uptime you demand. And its powerful engine and efficient hydraulic system allow higher working speeds for fast cycle times. The result is higher productivity and lower overall owning and operating costs.SAFETY

- Excellent visibility thanks to cab position that provides clear view to the digging and loading areas, floor window that provides a view to the tracks, LED lighting, and optional camera monitoring system.

- Emergency egress ladder with a self-closing door located in direct proximity to the cab.

- Safer access with 45-degree powered access stairway that features emergency lowering via a nitrogen accumulator, which ensures it remains operational even when engines shut off.

- Safer electrical and/or mechanical maintenance thanks to lockable starter and battery isolation switch cabinet.

- Safer service with improved sealing between engines and hydraulic pumps, improved routing and separation of hydraulic lines and electric cables.

OPERATOR CAB

- Improved operator comfort with Cat Next Gen heated and cooled seat and integrated joysticks.

- First-in-class and patented 3-seat design, including elevated full-size trainer’s seat and laptop work desk.

- New and improved air conditioning system.

- Reduced noise and temperature control thanks to superior insulation.

- Productivity-boosting Operator Assist – Enhanced Motion Control, which reduces fatigue and helps inexperienced operators more confidently load material.

RELIABILITY & DURABILITY

- Improved structures, including increased weight, strengthened superstructure and increased thickness in several locations.

- 33% longer service life for new and enlarged slew ring.

- New undercarriage with long-life components, frame and electronics.

- New crawler frame and Cat undercarriage with HD rollers, HD idlers, HD track, and track tensioning.

- New and improved engine design that improves reliability and extends gallons consumed before first overhaul by 10%, which also contributes to longer engine life.

PRODUCTIVITY & PERFORMANCE

- Up to 15% greater efficiency through Hydraulic Optimization, which dynamically assigns individual pumps or groups of pumps to deliver the exact flow and pressure that each hydraulic function requires.

- Faster cycle times and improved energy efficiency delivered by closed-loop swing system, which also generates less heat.

- Greater operator control thanks to five circuit hydraulics that allow for two cylinder motions, two travel motions, and swing to be controlled simultaneously.

- Easier and faster face shovel operation with unique TriPower face shovel design, which generates superior mechanical leverage and control.

- Increased productivity and greater uptime with the twin engine concept, which enables up to 65% of full production with a single engine.

BUCKETS & GET

- Buckets and ground engaging tools (GET) designed to maximize durability and productivity and ideally matched to your shovel and application.

- Integrated to work as part of a machine system — helping you achieve high productivity and the lowest cost per ton.

- Variety of sizes and material densities for the ideal match to your shovel and application.

- Deliver optimal payload when combined with Cat GET and wear components.

- Wear packages that protect your investment, including special liner material and lip shroud, wing shrouds and heel shrouds.

CONNECTIVITY & TECHNOLOGY

- Greater connectivity with improved Product Link™ Elite system, which increases the availability of data provided by the 6060.

- Additional performance and reliability advantages through integration of proven and validated Cat electronics.

- Intuitive, informative onboard electronics that help operators be more productive.

- Enhanced diagnostic capabilities and troubleshooting functions with factory-installed Monitoring and Diagnostic System.

- Connectivity features and the integration of Cat MineStar™ Health offerings enable a proactive approach to maintenance.

SERVICEABILITY

- More room in the service compartment, plus easy access to slew gearboxes, rotary distributor, oil cooler and more.

- Clear arrangement of components on the superstructure for easy access and serviceability.

- Hose assemblies that can be built locally using all Cat material.

- Access to Cat Electronic Technician, which helps dealer service personnel more easily diagnose and prevent issues.

- Reduced maintenance downtime thanks to exchange intervals for engine oil and engine filters that have been increased from 500 to 1,000 hours

SUSTAINABILITY

- Reduced fuel burn thanks to 10% improvement in hydraulic efficiency.

- Reduced emissions with engines that satisfy Tier 4 standards and eliminate the need for Diesel Exhaust Fluid (DEF) — saving time and cost during maintenance.

- Less heat and improved efficiency with the closed-loop swing circuit.

- Reduced owning and operating costs thanks to increased commonality of systems and components, plus a reduction in unique part numbers.

- Preservation of raw materials, energy conservation and reduced emissions through the Cat Reman program, which returns end-of-life components to like-new condition.

- Standard Equipment

- Optional Equipment

- Specs

- Docs

Standard Equipment

- 2 x Cat 3512E engines

- Cat Powertrain

- Aftertreatment System (used in highly regulated countries only): -Diesel Oxidation Catalysts (DOCs) -Non-DEF solution

- Air-to-Air After Cooling (ATAAC)

- Turbocharger

- Hydraulically driven radiator fan

- Electronically controlled fan speed

- Micro processed engine management

- Heavy-duty air filters

- Two-stage fuel filter with series filtration

- High-capacity water seperator

- Starting aid -- automatic ether

- Exhaust manifold and turbo heat shields

- Dual 24 V electric starters per engine

- Automatic engine idle shut down

- Automatic fuel priming

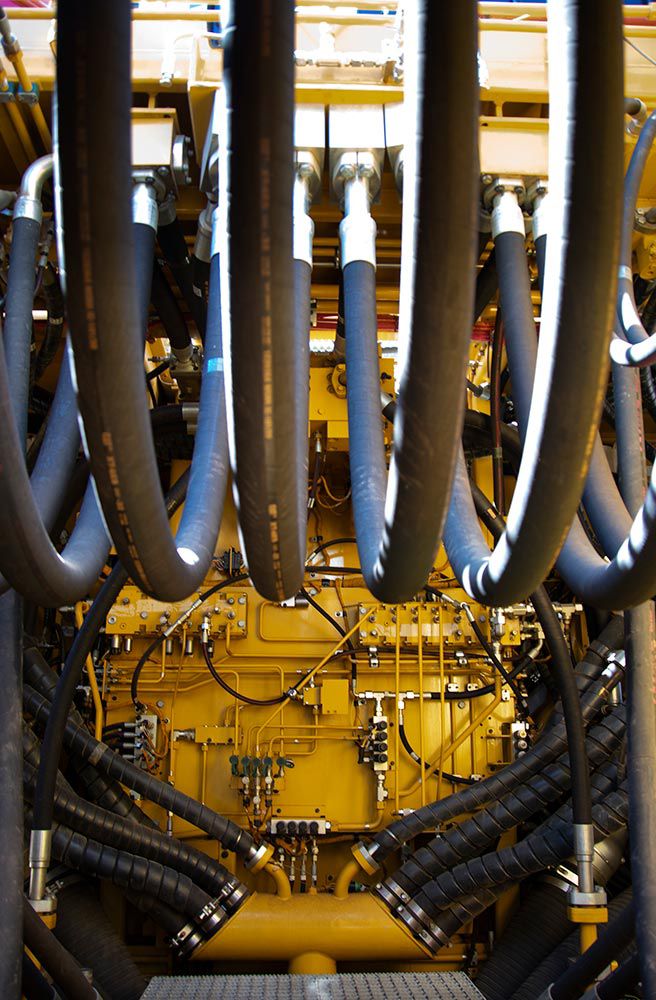

- Hydraulics

- Hydraulic Optimization

- Operator Assist: Enhanced Motion Control

- Cat Hydraulic Hose assemblies

- Pump managing system with: -Electronic load limit control -Flow on demand -Automatic zero flow regulation -Automatic engine rpm reduction -Reduced oil flow at high hydraulic oil or engine temperature

- Pressure cut-off for main pumps

- Cooling of pump transmission gear oil

- Closed loop swing circuit

- Pressure testing points

- Full-flow high-pressure filters (100 μm), main pumps

- High pressure filters (100 μm), closed swing circuit

- Full-flow filters (10 μm), return circuit

- Pressure filters swing charge circuit (40 μm)

- Pressure filters pilot circuit (6 μm)

- Transmission oil filters (40 μm)

- Boom float valve (FS and BH)

- Stick float valve (FS)

- Electrical System

- 6 Maintenance-free batteries

- Lockable battery isolator switch

- Lockable starter isolator switch

- 13 LED high-brightness working flood lights

- 17 LED service lights

- 2 acoustic travel alarms -forward and reverse (power module, oil cooler module)

- 2 electric horns (1 cab module, 1 oil cooler module)

- Undercarriage

- HD tracks with cast double-grouser track pads

- 1400 mm (4'7") wide track pads

- HD fixed axle carrier and load rollers

- HD fixed axle idlers

- Automatic hydraulic retarder valve

- Hinged travel motor covers

- Hardened running surfaces of sprockets, idlers, rollers, pad links, teeth contact areas

- Fully hydraulic self-adjusting track tensioning system with piston accumulators

- Automatic Lubrication System

- Rectangular grease container (fill via service station)

- Lubricated pinion in swing ring

- Grease filters (200 μm)

- Operator Environment

- Single hydraulically driven HVAC system

- In-floor window with removable grate

- Pneumatically cushioned and multiadjustable comfort seat with: -Heating and cooling -Lumbar support -2-point safety belt -Head and arm rests -Safety switch for automatic motion shutdown

- Independently adjustable seat consoles with integrated joysticks

- Electronic-Hydraulic Servo Control

- Elevated full-size trainer seat with 2-point safety belt and laptop desk

- Additional fold-away auxiliary seat with 2-point safety belt

- Three cup holders

- FM/AM radio with USB and AUX input

- Parallel intermittent wiper/washer

- Roller blinds

- Monitoring system with 254 mm (10 in) color touchscreen

- 45° stairway from engine bay to operator cab

- Powered 45° access stairway

- Heated mirror on LH side

- Camera monitoring system (Right and rear cameras, 2 lights, and additional display)

- Level indicators for length and crosswise inclination

- Document Storage

- Front Attachment

- Service access holes from both sides in boom and stick (FS and BH)

- Boom and stick thermally stress relieved after welding

- Catwalks with rails at boom (FS and BH)

- Wear Package (as per bucket selection)

- Cat Technology

- Cat Product Link™ Elite (Cellular)

- Cat MineStar™ Solutions Ready

- Service and Maintenance

- Engine oil exchange interval -- 500 hours

- Hydraulic oil change interval -10,000 hours

- Scheduled Oil Sampling (S·O·SSM) ports

- Retractable ground level service station with quick couplings for: -Diesel fuel -Engine coolant -left/right engines -Pump transmission gear oil -left/right engines -Engine oil -left/right engines -Engine oil extension tanks -Hydraulic oil -Grease -Swing transmission gear oil

- Cat battery charging connector

- Indicator lights

- Cat Electronic Technician service port

- Dirt wiper at swivel

- Safety and Security

- Emergency stop switches: 2 in cab, 5 in engine module, 1 at ground level service station, 1 pull rope accessible from ground level

- Operator Protective Guard (Top Guard)

- All-round safety glass

- Emergency egress ladder

- Maintenance

- ISO or ANSI decals

Optional Equipment

- GENERAL

- Custom paint

- SUPERSTRUCTURE

- Oil change interval extension for engine oil up to 500 hours, with optional extension to 1,000 hours

- Rectangular grease container, 710 L (188 gal), filled via service station

- Various cold-weather options for temperatures below -10°; 400 V, 50 Hz and 208 V, 60 Hz

- CAB

- Dual hydraulically driven HVAC system for redundancy

- Cab heating

- Camera monitoring system with two cameras, two lights, and additional display

- UNDERCARRIAGE

- Track pad width 1400 mm (4 ft 7 in)

- Belly plate for undercarriage protection

- Additional optional equipment available on request.

Specs

Overview

Long Name:

6060 Hydraulic Mining Shovel

Name:

6060

Brand:

Cat

Status:

Current

General

Engine Output - SAE J1995

3015 hp / 2248 kW

Bucket Payload

67 ton (US) / 61 t

Operating Weight

660 ton (US) / 599 t

Note

Specifications shown above apply to Face Shovel configuration. Backhoe and Frontless configurations are also available.

Engine

Engine Model

2 x Cat 3512E

Diesel Engines

Rated Speed

1,800 min-1 (1,800 rpm)

Diesel Engine - Lesser Regulated

Gross Power - SAE J1995

3025 hp / 2256 kW

Net Power - ISO 9249

2990 hp / 2229 kW

Net Power - SAE J1349

2821 hp / 2103 kW

Emissions

Optimized for fuel consumption.

Diesel Engine - Highly Regulated

Gross Power - SAE J1995

3015 hp / 2248 kW

Net Power - SAE J1349

2810 hp / 2095 kW

Net Power - ISO 9249

2979 hp / 2221 kW

Emissions

Meets U.S. EPA Tier 4 Final emission requirements. These engines participate in the U.S. EPA averaging, banking, and trading provisions.

Diesel Engines

Number of Cylinders - Each Engine

12

Bore

6.69 in / 170 mm

Stroke

8.46 in / 215 mm

Displacement

3574 in³ / 58.6 l

Aspiration

Turbocharged and charge air-cooled

Components (1)

Non-DEF Aftertreatment system with Diesel Oxidation Catalysts (DOCs)

Components (2)

High-capacity water separator

Components (3)

Two-stage fuel filter with series filtration

Components (4)

Heavy-duty air filters

Components (5)

Microprocessed engine management

Components (6)

Hydraulically driven radiator fan with electronically controlled fan speed

Components (7)

Exhaust manifold and turbo heat shields

Electrical System

System Voltage

24 V

Batteries in Series/Parallel Installation

6 x 210 Ah; 12 V each; 630 Ah 24 V in total

Components (1)

6 maintenance-free batteries

Components (2)

Lockable battery isolator switch

Components (3)

Lockable starter isolator switch

Components (4)

13 LED high-brightness working flood lights

Components (5)

17 LED service lights

Components (6)

2 electric horns (1 cab module; 1 oil cooler module)

Operating Weights

6060 FS - Standard Track Pads

4.58 ft / 1400 mm

6060 FS - Operating Weight

1320110 lb / 598800 kg

6060 FS - Ground Pressure

26.6 N/cm2 (38.5 psi)

Backhoe - Standard Track Pads

4.58 ft / 1400 mm

Backhoe - Operating Weight

1323860 lb / 600500 kg

Backhoe - Ground Pressure

26.7 N/cm2 (38.7 psi)

Note

Operating weights include: base machine, front attachment, standard track pads, standard rock bucket, 100% fuel and lubricants.

Service Refill Capacities

Fuel Tank

3136 gal (US) / 11870 l

Hydraulic Tank

1876 gal (US) / 7100 l

Hydraulic System - Including Tank

2483 gal (US) / 9400 l

Engine Oil

86.6 gal (US) / 328 l

Cooling System

211.4 gal (US) / 800 l

Swing Drive

42.4 gal (US) / 160 l

Grease Tank

188 gal (US) / 710 l

Hydraulic System with Pump Managing System

Main Pumps - Diesel Version

8 variable swash plate pumps

Main Pumps - Maximum Oil Flow - Diesel Version

8 x 650 L/min (8 x 172 gal/min)

Maximum Pressure - Attachment

4640 psi / 320 bar

Maximum Pressure - Travel

5220 psi / 360 bar

Swing Pumps - Diesel Version

4 reversible swash plate pumps

Swing Pumps - Maximum Oil Flow - Diesel Version

4 x 352 L/min (4 x 93 gal/min)

Maximum Pressure - Swing Pumps

5075 psi / 350 bar

Hydraulic Oil Cooling

Oil Flow of Cooling Pumps

4 x 488 L/min (4 x 129 gal/min)

Components

4 cooling fans

Diameter - Fan

46 in / 1170 mm

Features (1)

Cooling system fully independent of all main circuits, i.e. controlled cooling capacity is available whenever engine is running

Features (2)

Fan speed and flow of oil to the coolers are thermostatically controlled

Features (3)

Extremely high cooling efficiency to ensure optimum oil temperature

Features (4)

Gear-type cooling pumps supplying high-volume, low-pressure oil to fans and aluminum coolers

Swing System

Swing Drive

4 compact planetary transmissions with axial piston motors

Parking Brakes

Wet multiple disc brake, spring loaded/hydraulically released

Maximum Swing Speed

3.8 r/min / 3.8 r/min

Swing Ring

Triple-race roller bearing with sealed internal gearing

Features (1)

Dirt wipers at swing ring to prevent build-up of debris between swing ring and carbody

Features (2)

Closed-loop swing circuit with torque control

Features (3)

Hydraulic braking of the swing motion by counteracting control

Features (4)

All raceways and the internal gearing of swing ring, supplied by automatic central lubrication system

Undercarriage

Travel Speed - 1st Stage - Maximum

0.68 mile/h / 1.1 km/h

Travel Speed - 2nd Stage - Maximum

0.99 mile/h / 1.6 km/h

Maximum Tractive Force

661160 lb / 2942 kN

Gradeability - Travel Drives - Maximum

39 % / 39 %

Track Pads - Each Side

42

Bottom Rollers - Each Side

7

Support Rollers - Each Side

2 plus a skid plate in between

Travel Drives - Each Side

1 planetary transmission with 2 two-stage axial piston motors

Components (1)

HD tracks with cast double-grouser track pad

Components (2)

HD fixed axle rollers and idlers

Components (3)

Hardened running surfaces of sprockets, idlers, rollers, pad links, and teeth contact areas

Components (4)

Acoustic travel alarm (forward and reverse)

Components (5)

Fully hydraulic, self-adjusting track tensioning system with piston accumulator

Components (6)

Automatic hydraulic retarder valve to prevent over-speed on downhill travel

Operator's Cab

Operator's Eye Level - Approximately

24.91 ft / 7.6 m

Internal Dimensions of Cab - Length

7.33 ft / 2230 mm

Internal Dimensions of Cab - Width

5.33 ft / 1625 mm

Internal Dimensions of Cab - Height

6.75 ft / 2070 mm

Components (1)

Single hydraulically driven HVAC System, with dual system option

Components (2)

In-floor window with removable grate

Components (3)

Pneumatically cushioned and multi-adjustable comfort seat with heating, cooling, and lumbar support

Components (4)

Independently adjustable seat consoles with integrated joysticks

Components (5)

Operator Protective Guard (Top Guard) (ISO 10262:1998)

Components (6)

Elevated full-size trainer seat with safety belt and laptop desk

Components (7)

Additional fold-away auxiliary seat with safety belt

Components (8)

Operator Presence switch

Components (9)

Monitoring system with 254 mm (10 in) touch screen

Components (10)

Powered 45 degree access stairway

Components (11)

Emergency egress ladder

Components (12)

FM/AM radio with USB and AUX input

Components (13)

Roller blinds on 3 front windows

Components (14)

3 cup holders

Components (15)

Cat Electronic Technician service port

Automatic Lubrication System

Capacity - Grease Container

188 gal (US) / 710 l

Type (1)

Dual-circuit system with hydraulically driven heavy-duty pumps and electronic time relay control to adjust the pause/lube times

Type (2)

System failures displayed by monitoring system

Type (3)

Grease filters (200 µm) between service station and container as well as directly behind grease pump

Type (4)

Main lube system connections include: pivot points of attachment, bucket and cylinders, raceways of swing roller bearing, and 2 greasing pinions for the internal gearing of swing ring

Attachments

Shovel attachment with unique TriPower kinematics ensuring the following main features: (1)

Automatic roll-back limiter to prevent material spillage; Kinematic assistance to hydraulic forces

Shovel attachment with unique TriPower kinematics ensuring the following main features: (2)

Horizontal Automatic constant-angle bucket guidance; Vertical Automatic constant-angle bucket guidance

Shovel attachment with unique TriPower kinematics ensuring the following main features: (3)

Constant boom momentum throughout the entire lift arc; Crowd force assistance

All buckets (FS and BH) are equipped with a wear package consisting of: (1)

Special liner material covering main wear areas inside and outside of bucket and lip shrouds between teeth

All buckets (FS and BH) are equipped with a wear package consisting of: (2)

Wing shrouds on side walls and heel shrouds at bottom edges

Type (1)

Catwalks with rails at booms (FS and BH)

Type (2)

Guards for shovel cylinders (FS)

Type (3)

Pressure-free lowering of boom (FS and BH) and stick (FS) by means of a float valve

Type (4)

Service access holes from both sides of boom (FS and BH) and stick (FS)

Type (5)

Welding procedures allow for internal counter-welding (double prep weld) wherever possible

Type (6)

Booms and sticks are stress-relieved after welding

Type (7)

Booms and sticks are torsion-resistant, welded box design of high-tensile steel with massive steel castings at pivot areas

Type (8)

Special wear packages for highly abrasive materials available upon request

Digging Forces

Maximum Crowd Force

494410 lb / 2200 kN

Maximum Breakout Force

388780 lb / 1730 kN

Working Ranges

Maximum Digging Height

51.17 ft / 15.6 m

Maximum Digging Reach

54.17 ft / 16.5 m

Maximum Digging Depth

9.17 ft / 2.8 m

Standard Bucket Capacity

Face Shovel (heaped 2:1)

44.5 yd³ / 34 m³

Backhoe Attachment (BH) - Digging Forces

Stick Digging Force - ISO

295740 lb / 1316 kN

Bucket Digging Force - ISO

274840 lb / 1223 kN

Backhoe Attachment (BH) - Working Range

Maximum Digging Height

52.83 ft / 16.1 m

Maximum Digging Reach

62.33 ft / 19 m

Maximum Digging Depth

29.17 ft / 8.9 m

Standard Bucket Capacity

Backhoe (heaped 1:1)

44.5 yd³ / 34 m³

Retractable Service Station

Installation

Retractable service station installed underneath the engine module and easily accessible from ground.

Equipped With (1)

Quick couplings for: Diesel fuel, Engine coolant - left/right engine, Pump transmission gear oil - left/right engine, Engine oil - left/right engine, Hydraulic oil tank, and grease container

Equipped With (2)

Cat jump-start socket

Equipped With (3)

Indicator lights

SEE HOW 6060 COMPARES AGAINST FREQUENTLY COMPARED PRODUCTS.

Hydraulic Mining Shovels

6060

- Brand

- Cat

- Status

- Current

- Engine Output - SAE J1995

- 3015 hp / 2248 kW

- Bucket Payload

- 67 ton (US) / 61 t

- Operating Weight

- 660 ton (US) / 599 t

- Note

- Operating weights include: base machine, front attachment, standard track pads, standard rock bucket, 100% fuel and lubricants.

- Emissions

- Meets U.S. EPA Tier 4 Final emission requirements. These engines participate in the U.S. EPA averaging, banking, and trading provisions.

- Number of Cylinders - Each Engine

- 12

- Bore

- 6.69 in / 170 mm

- Stroke

- 8.46 in / 215 mm

- Displacement

- 3574 in³ / 58.6 l

- Aspiration

- Turbocharged and charge air-cooled

- Components (1)

- Single hydraulically driven HVAC System, with dual system option

- Components (2)

- In-floor window with removable grate

- Components (3)

- Pneumatically cushioned and multi-adjustable comfort seat with heating, cooling, and lumbar support

- Components (4)

- Independently adjustable seat consoles with integrated joysticks

- Components (5)

- Operator Protective Guard (Top Guard) (ISO 10262:1998)

- Components (6)

- Elevated full-size trainer seat with safety belt and laptop desk

- Components (7)

- Additional fold-away auxiliary seat with safety belt

- System Voltage

- 24 V

- Batteries in Series/Parallel Installation

- 6 x 210 Ah; 12 V each; 630 Ah 24 V in total

- Swing Drive

- 4 compact planetary transmissions with axial piston motors

- Main Pumps - Maximum Oil Flow - Diesel Version

- 8 x 650 L/min (8 x 172 gal/min)

- Maximum Pressure - Attachment

- 4640 psi / 320 bar

- Maximum Pressure - Travel

- 5220 psi / 360 bar

- Swing Pumps - Maximum Oil Flow - Diesel Version

- 4 x 352 L/min (4 x 93 gal/min)

- Maximum Pressure - Swing Pumps

- 5075 psi / 350 bar

- Diameter - Fan

- 46 in / 1170 mm

- Swing Ring

- Triple-race roller bearing with sealed internal gearing

- Travel Speed - 1st Stage - Maximum

- 0.68 mile/h / 1.1 km/h

- Travel Speed - 2nd Stage - Maximum

- 0.99 mile/h / 1.6 km/h

- Maximum Tractive Force

- 661160 lb / 2942 kN

- Track Pads - Each Side

- 42

- Bottom Rollers - Each Side

- 7

- Support Rollers - Each Side

- 2 plus a skid plate in between

- Travel Drives - Each Side

- 1 planetary transmission with 2 two-stage axial piston motors

- Operator's Eye Level - Approximately

- 24.91 ft / 7.6 m

- Internal Dimensions of Cab - Length

- 7.33 ft / 2230 mm

- Internal Dimensions of Cab - Width

- 5.33 ft / 1625 mm

- Internal Dimensions of Cab - Height

- 6.75 ft / 2070 mm

- Components (8)

- Operator Presence switch

- Components (9)

- Monitoring system with 254 mm (10 in) touch screen

- Components (10)

- Powered 45 degree access stairway

- Components (11)

- Emergency egress ladder

- Components (12)

- FM/AM radio with USB and AUX input

- Components (13)

- Roller blinds on 3 front windows

- Capacity - Grease Container

- 188 gal (US) / 710 l

- Type (1)

- Catwalks with rails at booms (FS and BH)

- Type (2)

- Guards for shovel cylinders (FS)

- Type (3)

- Pressure-free lowering of boom (FS and BH) and stick (FS) by means of a float valve

- Type (4)

- Service access holes from both sides of boom (FS and BH) and stick (FS)

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (1)

- Automatic roll-back limiter to prevent material spillage; Kinematic assistance to hydraulic forces

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (2)

- Horizontal Automatic constant-angle bucket guidance; Vertical Automatic constant-angle bucket guidance

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (3)

- Constant boom momentum throughout the entire lift arc; Crowd force assistance

- All buckets (FS and BH) are equipped with a wear package consisting of: (1)

- Special liner material covering main wear areas inside and outside of bucket and lip shrouds between teeth

- All buckets (FS and BH) are equipped with a wear package consisting of: (2)

- Wing shrouds on side walls and heel shrouds at bottom edges

- Type (5)

- Welding procedures allow for internal counter-welding (double prep weld) wherever possible

- Type (6)

- Booms and sticks are stress-relieved after welding

Selected Model

Hydraulic Mining Shovels

6040

- Brand

- Cat

- Status

- Current

- Engine Output - SAE J1995

- 2079 hp / 1550 kW

- Bucket Payload

- 43.7 ton (US) / 39.6 t

- Operating Weight

- 446 ton (US) / 404.6 t

- Note

- 1600 mm track pads available as option

- Emissions

- Meets U.S. EPA Tier 4 Final and EU Stage V emission standards

- Number of Cylinders - Each Engine

- 12

- Bore

- 5.71 in / 145 mm

- Stroke

- 6.38 in / 162 mm

- Displacement

- 1959 in³ / 32.1 l

- Aspiration

- Turbocharged and air-to-air aftercooled

- Components (1)

- Switch in seat cushion to automatically neutralize the hydraulic controls when operator leaves the seat

- Components (2)

- Pneumatically cushioned and multi-adjustable comfort seat with lumbar support, seat heating, safety belt, head- and armrests

- Components (3)

- Roller blinds at all windows

- Components (4)

- Windshield with parallel intermittent wiper/washer

- Components (5)

- All-round safety glass, armored windshield and sliding side window

- Components (6)

- Operator Protective Guard (Top Guard)

- Components (7)

- Single HVAC with option for Dual HVAC

- System Voltage

- 24V

- Batteries in Series/Parallel Installation

- 6 x 210 Ah - 12 V each; 630 Ah - 24 V in total

- Swing Drive

- 3 compact planetary transmissions with axial piston motors

- Main Pumps - Maximum Oil Flow - Diesel Version

- 4 x 724 L/min (4 x 191 gal/min)

- Maximum Pressure - Attachment

- 4350 psi / 300 bar

- Maximum Pressure - Travel

- 5080 psi / 350 bar

- Swing Pumps - Maximum Oil Flow - Diesel Version

- 4 x 321 L/min (4 x 85 gal/min)

- Maximum Pressure - Swing Pumps

- 5080 psi / 350 bar

- Diameter - Fan

- 2 × 1524 mm (2 × 60 in)

- Swing Ring

- Triple-race roller bearing with sealed internal gearing

- Travel Speed - 1st Stage - Maximum

- 0.93 mile/h / 1.5 km/h

- Travel Speed - 2nd Stage - Maximum

- 1.55 mile/h / 2.5 km/h

- Maximum Tractive Force

- 471260 lb / 2097 kN

- Track Pads - Each Side

- 42

- Bottom Rollers - Each Side

- 7

- Support Rollers - Each Side

- 2 plus a skid plate in between

- Travel Drives - Each Side

- 1 planetary transmission with 2 two-stage axial piston motors

- Operator's Eye Level - Approximately

- 22.31 ft / 6.8 m

- Internal Dimensions of Cab - Length

- 7.22 ft / 2200 mm

- Internal Dimensions of Cab - Width

- 5.25 ft / 1600 mm

- Internal Dimensions of Cab - Height

- 7.05 ft / 2150 mm

- Components (8)

- Joystick controls integrated in independently adjustable seat consoles

- Components (9)

- Fold-away auxiliary seat with safety belt

- Components (10)

- External sun shields at side and rear windows

- Components (11)

- Sliding emergency ladder (kick-down type) with ladder cage

- Components (12)

- Machine access via retractable access stairway, stairway angle approximately 45 degrees, hydraulically operated

- Components (13)

- Robust instrument panel including large colored BCS screen with transflective technology

- Capacity - Grease Container

- 188 gal (US) / 710 l

- Type (1)

- Inspection hole in monoboom BH

- Type (2)

- Pressure-free lowering of boom (FS and BH) and stick (FS) by means of a float valve

- Type (3)

- Special wear packages for highly abrasive materials on request

- Type (4)

- Catwalks with rails at boom (FS and BH)

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (1)

- - Automatic roll-back limiter to prevent material spillage - Kinematic assistance to hydraulic forces

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (2)

- - Horizontal automatic constant-angle bucket guidance - Vertical automatic constant-angle bucket guidance

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (3)

- - Constant boom momentum throughout the whole lift arc - Crowd force assistance

- All buckets (FS and BH) are equipped with a wear package consisting of: (1)

- - Special liner material covering main wear areas inside and outside of bucket - Lip shrouds between teeth

- All buckets (FS and BH) are equipped with a wear package consisting of: (2)

- - Wing shrouds on side walls - Heel shrouds at bottom edges

- Type (5)

- Welding procedures allow for internal counter-welding (double prep weld) wherever possible

- Type (6)

- Boom and sticks are stress-relieved after welding

Hydraulic Mining Shovels

6030

- Brand

- Caterpillar

- Status

- Current

- Engine Output - SAE J1995

- 1649 hp / 1230 kW

- Bucket Payload

- 33 ton (US) / 30 t

- Operating Weight

- 324 ton (US) / 294 t

- Note

- Other track pads available on request. Operating weights include: base machine, front attachment, standard track pads, standard rock bucket, and 100% fuel and lubricants.

- Emissions

- Meets U.S. EPA Tier 4 Final and EU Stage V emission standards

- Number of Cylinders - Each Engine

- 12

- Bore

- 5.42 in / 137.7 mm

- Stroke

- 6 in / 152.4 mm

- Displacement

- 1648 in³ / 27 l

- Aspiration

- Turbocharged and air-to-air aftercooled

- Components (1)

- Under roof mounted heating ventilating and air conditioning system

- Components (2)

- External sun shields at side and rear windows

- Components (3)

- Robust instrument panel including large colored BCS screen with transflective technology

- Components (4)

- Board Control System (BCS) electronic monitoring and data logging system for vital signs and service data of engines, hydraulic system and lubrication system

- Components (5)

- Hydraulically operated 45 degree access stairway

- Components (6)

- Emergency egress ladder with ladder cage

- Components (7)

- Switch in seat cushion to automatically neutralize the hydraulic controls when operator leaves the seat

- System Voltage

- 24V

- Batteries in Series/Parallel Installation

- 4 x 210 Ah at 12V each; 420 Ah with 24V in total

- Swing Drive

- 2 compact planetary transmissions with axial piston motors

- Main Pumps - Maximum Oil Flow - Diesel Version

- 4 x 552 L/min (4 x 146 gal/min)

- Maximum Pressure - Attachment

- 4495 psi / 310 bar

- Maximum Pressure - Travel

- 5220 psi / 360 bar

- Swing Pumps - Maximum Oil Flow - Diesel Version

- 4 x 197 L/min (4 x 52 gal/min)

- Maximum Pressure - Swing Pumps

- 5076 psi / 350 bar

- Diameter - Fan

- 48 in / 1220 mm

- Swing Ring

- Triple-race roller bearing with sealed internal gearing

- Travel Speed - 1st Stage - Maximum

- 0.87 mile/h / 1.4 km/h

- Travel Speed - 2nd Stage - Maximum

- 1.68 mile/h / 2.7 km/h

- Maximum Tractive Force

- 360144 ft·lbf / 1602 kN

- Track Pads - Each Side

- 44

- Bottom Rollers - Each Side

- 7

- Support Rollers - Each Side

- 2 plus a skid plate in between

- Travel Drives - Each Side

- 1 planetary transmission with 2 two-stage axial piston motors

- Operator's Eye Level - Approximately

- 21.33 ft / 6.5 m

- Internal Dimensions of Cab - Length

- 7.22 ft / 2200 mm

- Internal Dimensions of Cab - Width

- 5.25 ft / 1600 mm

- Internal Dimensions of Cab - Height

- 7.05 ft / 2150 mm

- Components (8)

- Pneumatically cushioned and multi-adjustable comfort seat with lumbar support, seat heating, safety belt, head- and armrests

- Components (9)

- Roller blinds at all windows

- Components (10)

- Windshield with parallel intermittent wiper/washer

- Components (11)

- All-round safety glass, armored windshield and sliding side window

- Components (12)

- Operator Protective Guards (ISO 10262:1998 Level II

- Components (13)

- Joystick controls integrated in independently adjustable seat consoles

- Capacity - Grease Container

- 119 gal (US) / 450 l

- Type (1)

- Catwalks with rails at booms

- Type (2)

- Special wear packages for highly abrasive materials on request

- Type (3)

- Pressure-free lowering of boom (FS and BH) and stick (FS) by means of a float valve

- Type (4)

- Welding procedures allow for internal counter-welding (double prep weld) wherever possible

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (1)

- Automatic roll-back limiter to prevent material spillage and kinematic assistance to hydraulic forces

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (2)

- Horizontal automatic constant-angle bucket guidance and vertical automatic constant-angle bucket guidance

- Shovel attachment with unique TriPower kinematics ensuring the following main features: (3)

- Constant boom momentum throughout the whole lift arc and crowd force assistance

- All buckets (FS and BH) are equipped with a wear package consisting of: (1)

- Special liner material covering main wear areas inside and outside of bucket and lip shrouds between teeth

- All buckets (FS and BH) are equipped with a wear package consisting of: (2)

- Wing shrouds on side walls and heel shrouds at bottom edges

- Type (5)

- Booms and sticks are stress-relieved after welding

- Type (6)

- Booms and sticks are torsion-resistant, welded box design of high-tensile steel with solid steel castings at pivot areas