Electric Power

Diesel Generator Sets

From 6 to 5,720 ekW (7.5 to 7,150 kVA) of power potential, our diesel-fueled generator sets are built to world-class standards, for high efficiency, low fuel consumption and global emissions compliance. Our commercial and industrial generator sets come in a range of options to match your power needs, making selecting and installing simple. Discover power designed for your demands.

Minimum Rating

680 kVAMaximum Rating

680 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

680 kVAMaximum Rating

900 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

635 ekWMaximum Rating

800 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

680 kVAMaximum Rating

680 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

680 kVAMaximum Rating

680 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1000 kVAMaximum Rating

1400 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1000 kVAMaximum Rating

1400 kVAEmissions/Fuel Strategy

Low fuel, Low EmissionsMinimum Rating

890 ekWMaximum Rating

1250 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

890 ekWMaximum Rating

1250 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1360 kVAMaximum Rating

1600 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

1600 kVAMaximum Rating

1875 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

1500 kVAMaximum Rating

1500 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1360 kVAMaximum Rating

1625 kVAEmissions/Fuel Strategy

Low Fuel , Low EmissionsMinimum Rating

1600 kVAMaximum Rating

1875 kVAEmissions/Fuel Strategy

Low Fuel , Low EmissionsMinimum Rating

1230 ekWMaximum Rating

1500 ekWEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

1230 kWMaximum Rating

1500 kWEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

1600 ekWMaximum Rating

1750 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 2Minimum Rating

1230 ekWMaximum Rating

1500 ekWEmissions/Fuel Strategy

U.S. EPA CertifiedMinimum Rating

1600 kVAMaximum Rating

2000 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1600 kVAMaximum Rating

2000 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1450 ekWMaximum Rating

1750 ekWEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

1450 ekWMaximum Rating

1750 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1750 kVAMaximum Rating

2250 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

2000 kVAMaximum Rating

2500 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

2000 kVAMaximum Rating

2500 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

2000 kVAMaximum Rating

2250 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1750 kVAMaximum Rating

2250 kVAEmissions/Fuel Strategy

Low fuel, Low EmissionsMinimum Rating

1640 ekWMaximum Rating

2250 ekWEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

1640 ekWMaximum Rating

2250 ekWEmissions/Fuel Strategy

Low fuel, Low EmissionsMinimum Rating

1750 kVAMaximum Rating

2275 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1640 ekWMaximum Rating

1825 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

2500 kVAMaximum Rating

2750 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

2500 kVAMaximum Rating

2750 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1650 ekWMaximum Rating

2500 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 2Minimum Rating

1825 ekWMaximum Rating

2500 ekWEmissions/Fuel Strategy

U.S. EPA CertifiedMinimum Rating

2750 kVA (2850 kVA without fan)Maximum Rating

3000 kVA (3100 kVA without fan)Emissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

3000 kVAMaximum Rating

3500 kVAEmissions/Fuel Strategy

Tier 2 Equivalent - 1800 rpmMinimum Rating

2725 kVAMaximum Rating

3500 kVAEmissions/Fuel Strategy

U.S. EPA Cert. Tier 2 / Low NOxMinimum Rating

2500 ekWMaximum Rating

2750 ekWEmissions/Fuel Strategy

Tier 2, Low NOxMinimum Rating

2725 ekWMaximum Rating

3000 ekWEmissions/Fuel Strategy

Tier 2Minimum Rating

1775 kVAMaximum Rating

2688 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1650 ekWMaximum Rating

2000 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

2363 kVAMaximum Rating

3575 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1830 ekWMaximum Rating

2660 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

4400 kVAMaximum Rating

4850 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

3300 ekWMaximum Rating

4000 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

4700 kVAMaximum Rating

7520 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

3350 ekWMaximum Rating

5320 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

9.5 kVAMaximum Rating

9.5 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

7.5 kVAMaximum Rating

7.5 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

6.8 kVAMaximum Rating

9.5 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

8.0 ekWMaximum Rating

8.8 ekWEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

11 kVAMaximum Rating

11 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

13.5 kVAMaximum Rating

13.5 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

10.0 kVAMaximum Rating

13.5 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

12.0 ekWMaximum Rating

13.2 ekWEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

400 kVAMaximum Rating

400 kVAEmissions/Fuel Strategy

India CPCB/MoEFMinimum Rating

350 kVAMaximum Rating

450 kVAEmissions/Fuel Strategy

Low Fuel, R96/EUIIIaMinimum Rating

350 kVAMaximum Rating

450 kVAEmissions/Fuel Strategy

Low Fuel, R96/EUIIIaMinimum Rating

320 ekWMaximum Rating

400 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

320 ekWMaximum Rating

400 ekWEmissions/Fuel Strategy

EPA Stationary Emerg UseMinimum Rating

400 kVAMaximum Rating

400 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

450 kVAMaximum Rating

450 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

500 kVAMaximum Rating

500 kVAEmissions/Fuel Strategy

India CPCB/MoEFMinimum Rating

365 kVAMaximum Rating

550 kVAEmissions/Fuel Strategy

Tier 2 or Tier 3Minimum Rating

365 kVAMaximum Rating

550 kVAEmissions/Fuel Strategy

Low Fuel, Tier 2 or 3Minimum Rating

400 ekWMaximum Rating

500 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

320 ekWMaximum Rating

500 ekWEmissions/Fuel Strategy

Low Fuel, Tier 2, Tier 3, EU Stage IIIAMinimum Rating

500 kVAMaximum Rating

500 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

550 kVAMaximum Rating

550 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

2500 kVAMaximum Rating

3100 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

2500 ekWMaximum Rating

3365 ekWEmissions/Fuel Strategy

Low Fuel, Tier 2Minimum Rating

2500 ekWMaximum Rating

3100 ekWEmissions/Fuel Strategy

U.S. EPA Certified Tier 4Minimum Rating

3150 kVAMaximum Rating

4000 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

3150 ekWMaximum Rating

4000 ekWEmissions/Fuel Strategy

Low Fuel, Tier 2Minimum Rating

550 kVAMaximum Rating

715 kVAEmissions/Fuel Strategy

Low Fuel, China Nonroad III Emis StdsMinimum Rating

706 kVAMaximum Rating

850 kVAEmissions/Fuel Strategy

Low FuelMinimum Rating

550 kVAMaximum Rating

715 kVAEmissions/Fuel Strategy

Low Fuel, EU Stage IIIAMinimum Rating

600 kVAMaximum Rating

600 kVAEmissions/Fuel Strategy

India CPCB/MoEFMinimum Rating

455 ekWMaximum Rating

600 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

455 ekWMaximum Rating

600 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 2Minimum Rating

500 ekWMaximum Rating

600 ekWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

500 ekWMaximum Rating

750 ekWEmissions/Fuel Strategy

U.S. EPA CertifiedMinimum Rating

455 ekWMaximum Rating

500 ekWEmissions/Fuel Strategy

U.S. EPA Tier 4 FinalMinimum Rating

605 kVAMaximum Rating

605 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

660 kVAMaximum Rating

660 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

715 kVAMaximum Rating

715 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

780 kVAMaximum Rating

780 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

850 kVAMaximum Rating

850 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

16 kVAMaximum Rating

16 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

18 kVAMaximum Rating

18 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

22 kVAMaximum Rating

22 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

13.0 kVAMaximum Rating

22.0 kVAEmissions/Fuel Strategy

R96/EUIIIa EquivalentMinimum Rating

15.5 ekWMaximum Rating

20.0 ekWEmissions/Fuel Strategy

R96/EUIIIa EquivalentEmissions/Fuel Strategy

US EPA TIER 4I (EPA 40 CFR Part 1039 Interim Tier 4)Emissions/Fuel Strategy

US EPA TIER 4I (EPA 40 CFR Part 1039 Interim Tier 4)Emissions/Fuel Strategy

US EPA TIER 4I (EPA 40 CFR Part 1039 Interim Tier 4)Minimum Rating

635 ekWMaximum Rating

800 ekWEmissions/Fuel Strategy

Low Fuel, Tier 2 Nonroad EquivalentMinimum Rating

3300 ekW (60Hz), 4400 kVA (50Hz)Maximum Rating

3640 ekW (60Hz), 4850 kVA (50Hz)Emissions/Fuel Strategy

EPA Tier 4 Final, IMO Tier 2Minimum Rating

4400 ekW (60Hz), 5875 kVA (50Hz)Maximum Rating

4840 ekW (60Hz), 6500 kVA (50Hz)Emissions/Fuel Strategy

EPA Tier 4 Final, IMO Tier 2Minimum Rating

1650 ekW (60Hz), 2200 kVA (50Hz)Maximum Rating

1820 ekW (60Hz), 2425 kVA (50Hz)Emissions/Fuel Strategy

IMO Tier 2Minimum Rating

2200 ekW (60Hz), 2938 kVA (50Hz)Maximum Rating

2420 ekW (60Hz), 3250 kVA (50Hz)Emissions/Fuel Strategy

EPA Tier 4 Final, IMO Tier 2Minimum Rating

24.0 kVAMaximum Rating

65.0 kVAEmissions/Fuel Strategy

EU Stage II R96/EUIIIaMinimum Rating

27.0 ekWMaximum Rating

60.0 ekWEmissions/Fuel Strategy

EU Stage II & R96/EUIIIaMinimum Rating

45 ekWMaximum Rating

45 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

26 kVAMaximum Rating

26 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

33 kVAMaximum Rating

33 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

50.0 kVAMaximum Rating

50.0 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

50 ekWMaximum Rating

50 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

45.0 kVAMaximum Rating

49.2 kVAEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

40 ekWMaximum Rating

45 ekWEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

65 kVAMaximum Rating

65 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

60.0 kVAMaximum Rating

75.0 kVAEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

55.0 ekWMaximum Rating

60 ekWEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

910 kVAMaximum Rating

1500 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

1010 kVAMaximum Rating

1250 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

830 ekWMaximum Rating

1250 ekWEmissions/Fuel Strategy

Low Fuel, Tier 2 Nonroad StdsMinimum Rating

910 kVAMaximum Rating

910 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

910 kVAMaximum Rating

910 kVAEmissions/Fuel Strategy

Low Fuel, Low EmissionsMinimum Rating

50 kVAMaximum Rating

110 kVAEmissions/Fuel Strategy

EU Stage II & R96/EUIIIaMinimum Rating

36 ekWMaximum Rating

60 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

36 ekWMaximum Rating

100 ekWEmissions/Fuel Strategy

Non Regulated, EU Stage IIMinimum Rating

72 ekWMaximum Rating

100 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

80.0 kVAMaximum Rating

88.0 kVAEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

72.0 ekWMaximum Rating

80.0 ekWEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

110.0 kVAMaximum Rating

110.0 kVAEmissions/Fuel Strategy

EU Stage II R96Minimum Rating

100.0 kVAMaximum Rating

110.0 kVAEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

90.4 ekWMaximum Rating

100.0 ekWEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

88 kVAMaximum Rating

88 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

135 kVAMaximum Rating

220 kVAEmissions/Fuel Strategy

Non Regulated, EU Stage IIIAMinimum Rating

120 ekWMaximum Rating

175 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

114 ekWMaximum Rating

200 ekWEmissions/Fuel Strategy

Tier 3Minimum Rating

165 kVAMaximum Rating

165 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

135.0 kVAMaximum Rating

149.0 kVAEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

120.0 ekWMaximum Rating

120.0 ekWEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

180.0 kVAMaximum Rating

200.0 kVAEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

157.0 ekWMaximum Rating

174.0 ekWEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

200 kVAMaximum Rating

220 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

230 kVAMaximum Rating

330 kVAEmissions/Fuel Strategy

EU Stage IIIAMinimum Rating

180 ekWMaximum Rating

300 ekWEmissions/Fuel Strategy

EU Stage IIIA, Low FuelMinimum Rating

180 ekWMaximum Rating

300 ekWEmissions/Fuel Strategy

Low Fuel, Tier 3Minimum Rating

275 kVAMaximum Rating

275 kVAEmissions/Fuel Strategy

Non-CertifiedMinimum Rating

300 kVAMaximum Rating

300 kVAEmissions/Fuel Strategy

Non-CertifiedMinimum Rating

330 kVAMaximum Rating

330 kVAEmissions/Fuel Strategy

Non-CertifiedMinimum Rating

100 ekWMaximum Rating

100 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

1000 ekWMaximum Rating

1000 ekWEmissions/Fuel Strategy

U.S. EPA Tier 2Minimum Rating

125 ekWMaximum Rating

125 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

1250 ekWMaximum Rating

1250 ekWEmissions/Fuel Strategy

U.S. EPA Tier 2Minimum Rating

150 ekWMaximum Rating

150 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

175 ekWMaximum Rating

175 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

200 ekWMaximum Rating

200 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

250 ekWMaximum Rating

250 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

300 ekWMaximum Rating

300 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

350 ekWMaximum Rating

350 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

40 ekWMaximum Rating

40 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3, SCAQMD CompliantMinimum Rating

400 ekWMaximum Rating

400 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

450 ekWMaximum Rating

450 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

50 ekWMaximum Rating

50 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3, SCAQMD CompliantMinimum Rating

500 ekWMaximum Rating

500 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

550 ekWMaximum Rating

550 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

60 ekWMaximum Rating

60 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

600 ekWMaximum Rating

600 ekWEmissions/Fuel Strategy

EPA Stationary EmergencyMinimum Rating

80 ekWMaximum Rating

80 ekWEmissions/Fuel Strategy

U.S. EPA Cert., Tier 3Minimum Rating

1000 eKWMaximum Rating

1000 eKWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

110 kVAMaximum Rating

110 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

100 ekWMaximum Rating

100 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

1100 kVAMaximum Rating

1100 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1250 kVAMaximum Rating

1250 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1250 eKWMaximum Rating

1250 eKWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

1400 kVAMaximum Rating

1400 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

150 kVAMaximum Rating

150 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

132 ekWMaximum Rating

132 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

1500 kVAMaximum Rating

1500 kVAEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

163.9 kVAMaximum Rating

163.9 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

150 ekWMaximum Rating

150 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

200 kVAMaximum Rating

200 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

175 ekWMaximum Rating

175 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

217 kVAMaximum Rating

217 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

33.0 kVAMaximum Rating

33.0 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

30.0 ekWMaximum Rating

30.0 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

350 ekWMaximum Rating

350 ekWEmissions/Fuel Strategy

Low Fuel, R96/EUIIIaMinimum Rating

400 kVAMaximum Rating

400 kVAEmissions/Fuel Strategy

Non-Certified EmissionsMinimum Rating

400 ekWMaximum Rating

400 ekWEmissions/Fuel Strategy

Low Fuel, R96/EUIIIaMinimum Rating

450 kVAMaximum Rating

450 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

450 ekWMaximum Rating

450 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

50.0 kVAMaximum Rating

50.0 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

500 kVAMaximum Rating

500 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

500 ekWMaximum Rating

500 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

55.0 kVAMaximum Rating

55.0 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

550 kVAMaximum Rating

550 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

550 ekWMaximum Rating

550 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

600 ekWMaximum Rating

600 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

605 kVAMaximum Rating

605 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

65.0 kVAMaximum Rating

65.0 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

60 ekWMaximum Rating

60 ekWEmissions/Fuel Strategy

Non RegulatedMinimum Rating

660 kVAMaximum Rating

660 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

715 kVAMaximum Rating

715 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

800 eKWMaximum Rating

800 eKWEmissions/Fuel Strategy

Low Fuel ConsumptionMinimum Rating

88 kVAMaximum Rating

88 kVAEmissions/Fuel Strategy

Non RegulatedMinimum Rating

80 ekWMaximum Rating

80 ekWEmissions/Fuel Strategy

Non Regulated

Gas Generator Sets

Ranging from 100 to 4,500 ekW (100 to 4,500 kVA) in a single unit, our gas generator sets are easy to select, permit and install. Our industrial and commercial gas generator sets are proven for reliable operation with a wide range of gaseous fuels including natural gas, biogas from landfills and digesters, coal gas, propane and alternative fuels. We build durable, low life-cycle cost power systems that we integrate with controls, exhaust systems, fuel train, combined cooling heat & power skids and switchgear.

Voltage

120/208, 120/240, 277/480, 346/600 VACFrequency

60 HzVoltage

120/208, 120/240, 277/480, 346/600 VACFrequency

60 Hz

Mobile Generator Sets

The lifeblood of your business is reliable electric power. Mobile generators ensure that you'll never be without it. Connect a unit to your building. Take one to a remote location. Connect multiple units in parallel. Our natural gas and diesel mobile generators were engineered for easy transporting and fast installation

Rating Prime

910 ekW (1136 kVA)Frequency

60 HzVoltage

120 - 600VRating Prime

100 ekW (125 kVA)Frequency

60 HzVoltage

120 - 600VRating Prime

1825 ekW (2280 kVA)Frequency

60 HzVoltage

480/277 VRating Prime

182 ekW (228 kVA)Frequency

60 HzVoltage

120 - 600VRating Prime

264 eKW (330 kVA)Frequency

50/60 HzVoltage

120 - 600VRating Prime

27 ekW (35 kVA)Frequency

60 HzVoltage

120 - 600VRating Prime

340 ekW (425 kVA)Frequency

50/60 HzVoltage

120 - 600VRating Prime

455 ekW (568 kVA)Frequency

60 HzVoltage

120 - 600VRating Prime

47.5 ekW (60 kVA)Frequency

60 HzVoltage

120 - 600V

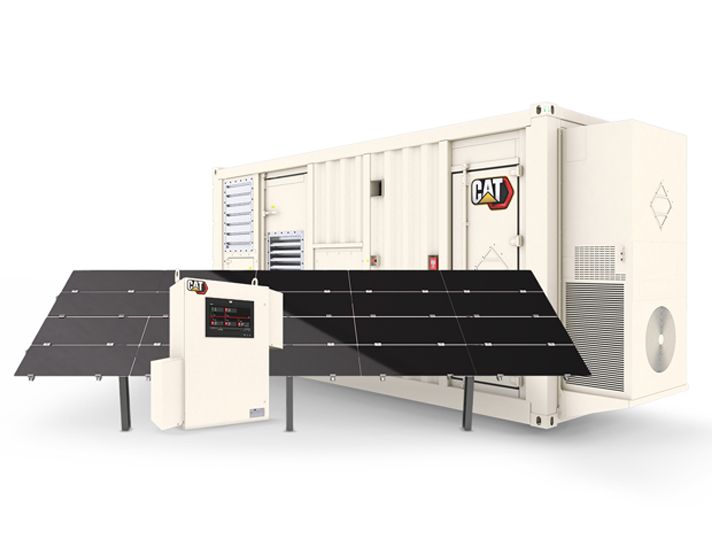

Battery Energy Storage Systems

Cat® Microgrids provide cost effective power for on- and off-grid communities and commercial or industrial installations. By combining renewable energy, from our photovoltaic solar modules and advanced energy storage solutions, with traditional generation, from utilities or generator sets, we can develop an energy system specifically designed for your needs. The Cat Microgrid combines all sources into a single, controllable entity to optimize the flow of energy so it can be produced at the lowest total costs.

Application

Energy Storage SystemModule Type

Integral part of Power Grid Stabilization and Energy Time Shift modulesRated Power

1000 kVA (1000kW 1PF)Application

Reserve Power CapacityModule Type

Energy StorageApplication

Peak ShavingModule Type

Energy Time ShiftApplication

Transient AssistModule Type

Grid stabilizationApplication

Transient AssistModule Type

Heavy Duty mobile Grid Stabilization

Switchgear and Paralleling Controls

Caterpillar offers switchgear suitable for applications ranging from single standby/load management to multi-unit utility paralleling installations.

Configuration

Application-specific switchgear with control logic designed to meet any customer's sequence of operations. Examples are 3+ Utilities, CHP applications, complex load shed schemes, etcModes of Operation

All modes of paralleling generator sets to each other and to other sources (utility, alternative fuels, wind, etc) can be supported. Caterpillar generation and control experts can design and program the most complex power schemes to meet your critical power needsApplication

LV and MV ( 208V - 38 kV) 50 / 60 HzConfiguration

Configurable PLC based switchgear capable of controlling and monitoring multiple generator sets, tie and load breakers in conjunction with downstream transfer switches for standby or emergency applicationsModes of Operation

Multi-unit Island and multi-unit standby mode with optional redundant controls and components.Application

LV and MV (208V - 38 kV)Configuration

IP4XModes of Operation

Switchgear integration options for multi generator and utility synchronising, load sharing, Peak Lopping/Shaving, AMF, Changeover, Load bank connection, Protection relay etc.Application

LV 380…480 VAC, 50 Hz, 3-Phase.Configuration

Configurable PLC based switchgear capable of controlling and monitoring multiple generator sets, tie, utility and load breakers for utility paralleling applicationsModes of Operation

Emergency Standby, Utility Import/Export, Peak shaving, and base load operations with redundant controls and components. Closed transition to/from generator powerApplication

LV and MV ( 208V - 38 kVConfiguration

Remote monitoring and control for up to 8 generator sets via high-speed network. Enables paralleling a group of EMCP 4.4 equipped generator sets to a single utility source.Modes of Operation

Emergency standby, island, utility parallelingApplication

LV and MV (208V - 38 kV)Configuration

Remote modular paralleling control system (Master Control Panel for the first 2 generator sets and optional tie breaker, separate add-on control panels for up to 8 additional generator sets, utility paralleling control, and distribution control)Modes of Operation

Emergency Standby with redundant master control, Utility paralleling, peak shaving, and closed transition to/from Generator Power (with optional utility control panel)Application

LV and MV (208V-27kV)

ATS ATC Breaker / Contactor

The ATC line of Automatic Transfer Switches are available in breaker or contactor based switches in sizes ranging from 30A through 5000A.

Rating Range

100 to 1200ATransfer Type

Bypass IsolationSwitch Type

Contactor BasedRating Range

40-1600ATransfer Type

Open / Closed TransitionSwitch Type

Contactor BasedRating Range

30-1000ATransfer Type

Open transitionSwitch Type

Molded CaseRating Range

200 to 5000ATransfer Type

Open TransitionSwitch Type

Power BreakerRating Range

200-5000ATransfer Type

Bypass isolation, Closed transitionSwitch Type

Power BreakerRating Range

30-5000ATransfer Type

Open / Closed / DelayedSwitch Type

Molded Case and Power BreakerRating Range

120 to 600V, single phase and three phase @ 50/60 HzTransfer Type

Switch application dependentSwitch Type

Switch application dependentRating Range

120 to 600V, single phase and three phase @ 50/60 HzTransfer Type

Switch application dependentSwitch Type

Switch application dependent

ATS MX Contactor

The MX line of Automatic Transfer Switches are contactor based switches in sizes ranging from 30A through 5000A.