Industrial

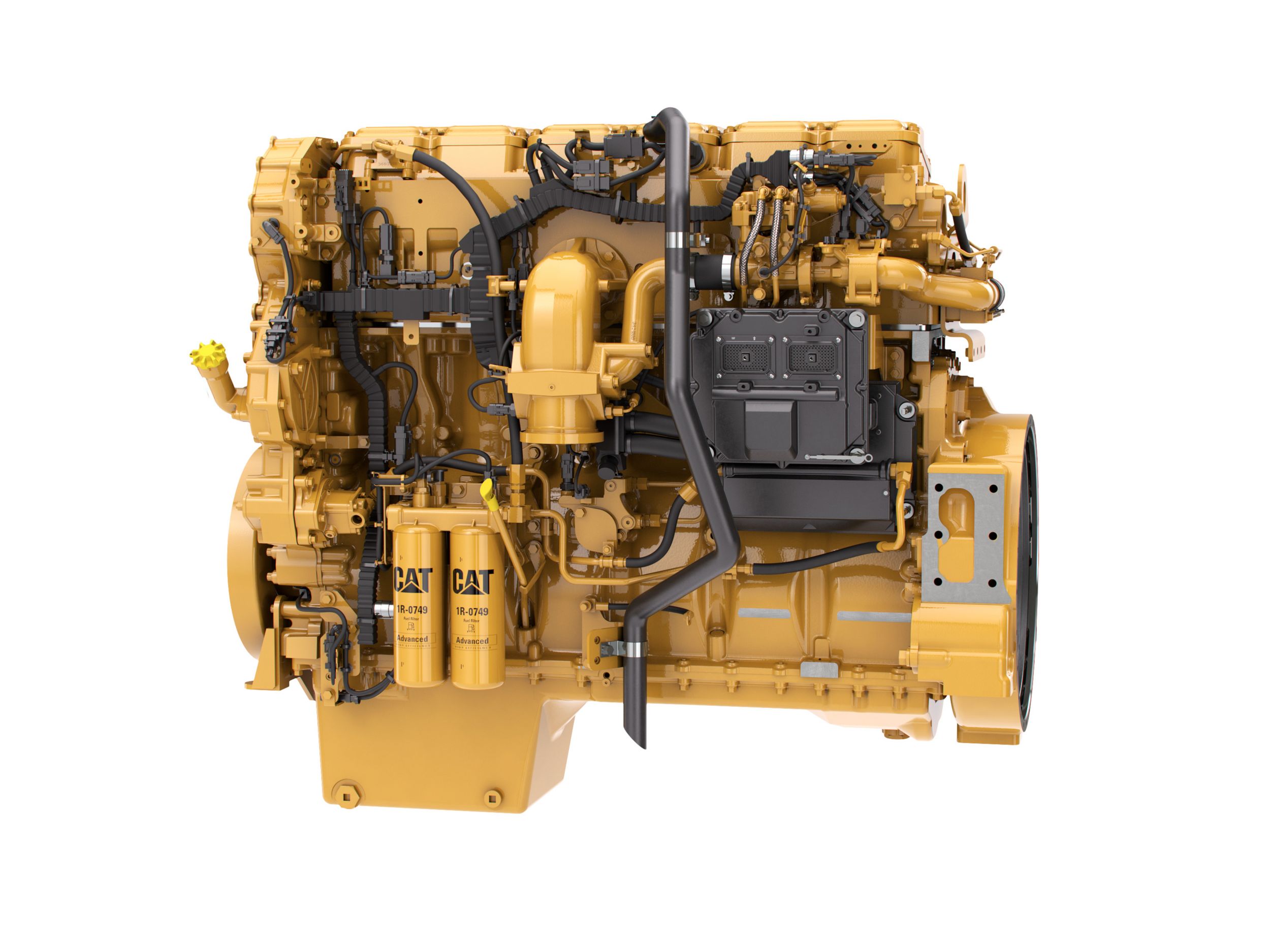

Industrial Diesel Engines

Cat engines with Tier 4 technology meet tough emissions standards and deliver the performance and efficiency you expect from Caterpillar.

Model

Maximum Power

Emissions

Maximum Torque

Maximum Power

130 HP / 97 kWEmissions

U.S. EPA Tier 2 Equivalent, EU Stage II EquivalentMaximum Torque

369 lb-ft @ 1400 rpm / 500 Nm @ 1400 rpmCompare Models

Maximum Power

465 HP / 347 kWEmissions

Non-CertifiedMaximum Torque

1602 lb-ft @ 1350 rpm / 2172 Nm @ 1350 rpmCompare Models

Maximum Power

1000 HP / 746 kWEmissions

Non-CertifiedMaximum Torque

3144 lb-ft @ 1450 rpm / 4263 Nm @ 1450 rpmCompare Models

Maximum Power

1100 HP / 820 kWEmissions

Non-CertifiedMaximum Torque

3211 lb-ft @ 1450 rpm / 4353 Nm @ 1450 rpmCompare Models

Maximum Power

1500 HP / 1119 kWEmissions

Non-CertifiedMaximum Torque

4580 lb-ft @ 1400 rpm / 6210 Nm @ 1400 rpmCompare Models

Maximum Power

1650 HP / 1231 kWEmissions

Non-CertifiedMaximum Torque

5296 lb-ft @ 1450 rpm / 7180 Nm @ 1450 rpmCompare Models

Maximum Power

1500 HP / 1120 kWEmissions

U.S. EPA Tier 2 EquivalentMaximum Torque

5259 lb-ft @ 1500 rpm / 7130 Nm @ 1500 rpmCompare Models

Maximum Power

2000 HP / 1492 kWEmissions

Non-CertifiedMaximum Torque

6189 lb-ft @ 1400 rpm / 8391 Nm @ 1400 rpmCompare Models

Maximum Power

2100 HP / 1506 kWEmissions

U.S. EPA Tier 2 Nonroad Equivalent Emission Standards (Not Currently EPA Certified)Maximum Torque

7563 lb-ft @ 1300 rpm / 10254 Nm @ 1300 rpmCompare Models

Maximum Power

2100 HP / 1566 kWEmissions

U.S. EPA Tier 4 Final, EU Stage VMaximum Torque

8275 lb-ft @ 1200 rpm / 11220 Nm @ 1200 rpmCompare Models

Maximum Power

2481 HP / 1850 kWEmissions

Non-CertifiedMaximum Torque

13424 lb-ft @ 820 rpm / 18200 Nm @ 820 rpmCompare Models

Maximum Power

3300 HP / 2460 kWEmissions

Non-CertifiedMaximum Torque

18219 lb-ft @ 820 rpm / 24700 Nm @ 820 rpmCompare Models

Maximum Power

4962 HP / 3700 kWEmissions

Non-CertifiedMaximum Torque

30848 lb-ft @ 800 rpm / 41822 Nm @ 800 rpmCompare Models

Maximum Power

6598 HP / 4920 kWEmissions

Non-CertifiedMaximum Torque

35692 lb-ft @ 820 rpm / 48390 Nm @ 820 rpmCompare Models

Maximum Power

13.7 HP / 10.2 kWEmissions

U.S. EPA Tier 4 Interim EquivalentMaximum Torque

22 lb-ft @ 2600 rpm / 29.7 Nm @ 2600 rpmCompare Models

Maximum Power

13.7 HP / 10.2 kWEmissions

U.S. EPA Tier 4 Final, EU Stage VMaximum Torque

22 lb-ft @ 2600 rpm / 29.7 Nm @ 2600 rpmCompare Models

Maximum Power

17.8 HP / 13.3 kWEmissions

U.S. EPA Tier 4 Final, EU Stage VMaximum Torque

32 lb-ft @ 1400 rpm / 44 Nm @ 1400 rpmCompare Models

Maximum Power

20.5 HP / 15.3 kWEmissions

U.S. EPA Tier 4 Interim EquivalentMaximum Torque

37.1 lb-ft @ 2400 rpm / 50.4 Nm @ 2400 rpmCompare Models

Maximum Power

28.2 HP / 21 kWEmissions

U.S. EPA Tier 4 Interim EquivalentMaximum Torque

49.4 lb-ft @ 2400 rpm / 67 Nm @ 2400 rpmCompare Models

Maximum Power

24 HP / 18.4 kWEmissions

U.S. EPA Tier 4 Final, EU Stage VMaximum Torque

63 lb-ft @ 1600 rpm / 86 Nm @ 1600 rpmCompare Models

Maximum Power

28.2 HP / 21 kWEmissions

China Nonroad Stage IVMaximum Torque

63.4 lb/ft / 86 N·mCompare Models

Maximum Power

40.2 HP / 30 kWEmissions

U.S. EPA Tier 4 Interim EquivalentMaximum Torque

83 lb-ft @ 1800 rpm / 112 Nm @ 1800 rpmCompare Models

Maximum Power

24.6 HP / 18.4 kWEmissions

U.S. EPA Tier 4 FinalMaximum Torque

63.4 lb-ft @ 1300 rpm / 86 Nm @ 1300 rpmCompare Models

Maximum Power

48 HP / 36 kWEmissions

EU Stage V, U.S. EPA Tier 4 FinalMaximum Torque

122 lb-ft @ 1600 rpm / 166 Nm @ 1600 rpmCompare Models

Maximum Power

25.3 HP / 18.9 kWEmissions

China Nonroad Stage IVMaximum Torque

72.2 lb-ft @ 1600 rpm / 97.9 Nm @ 1600 rpmCompare Models

Maximum Power

451 HP / 336 kWEmissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA, U.S. EPA Tier 3Maximum Torque

1516 lb-ft @ 1400 rpm / 2056 Nm @ 1400 rpmCompare Models

Maximum Power

536 HP / 400 kWEmissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA, U.S. EPA Tier 3Maximum Torque

1735 lb-ft @ 1400 rpm / 2353 Nm @ 1400 rpmCompare Models

Maximum Power

577 HP / 430 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIVMaximum Torque

1943 lb-ft @ 1400 rpm / 2634 Nm @ 1400 rpmCompare Models

Maximum Power

577 HP / 430 kWEmissions

China Nonroad IVMaximum Torque

1943 lb-ft @ 1400 rpm / 2634 Nm @ 1400 rpmCompare Models

Maximum Power

580 HP / 433 kWEmissions

U.S. EPA Tier 4 FinalMaximum Torque

1958 lb-ft @ 1400 rpm / 2655 Nm @ 1400 rpmCompare Models

Maximum Power

595 HP / 444 kWEmissions

China Nonroad III, U.S. EPA Tier 3 Equivalent, EU Stage IIIA EquivalentMaximum Torque

2004 lb-ft @ 1400 rpm / 2717 Nm @ 1400 rpmCompare Models

Maximum Power

580 HP / 433 kWEmissions

China Nonroad Stage IVMaximum Torque

1958 lb-ft @ 1600 rpm / 2655 Nm @ 1600 rpmCompare Models

Maximum Power

800 HP / 597 kWEmissions

China Nonroad III, U.S. EPA Tier 3 equivalent or U.S. EPA Tier 2 equivalent, EU Stage IIIA equivalent, or Non-certifiedMaximum Torque

2696 lb-ft @ 1400 rpm / 3655 Nm @ 1400 rpmCompare Models

Maximum Power

800 HP / 597 kWEmissions

EU Stage VMaximum Torque

2736 lb-ft @ 1500 rpm / 3710 Nm @ 1500 rpmCompare Models

Maximum Power

630 HP / 470 kWEmissions

China Nonroad Stage IVMaximum Torque

2178 lb-ft @ 1300 rpm / 2953 Nm @ 1200 rpmCompare Models

Maximum Power

74 HP / 55 kWEmissions

U.S. EPA & CARB Tier 4 Final, EU Stage VMaximum Torque

199 lb-ft @ 1600 rpm / 270 Nm @ 1600 rpmCompare Models

Maximum Power

66 HP / 49.2 kWEmissions

U.S. EPA Tier 4 Interim EquivalentMaximum Torque

153 lb-ft @ 1800 rpm / 208 Nm @ 1800 rpmCompare Models

Maximum Power

74 HP / 55 kWEmissions

China Nonroad Stage IVMaximum Torque

199 lb-ft @ 1600 rpm / 270 Nm @ 1600 rpmCompare Models

Maximum Power

74 HP / 55 kWEmissions

U.S. EPA & CARB Tier 4 Final, EU Stage VMaximum Torque

280 lb-ft @ 1360 rpm / 380 Nm @ 1360 rpmCompare Models

Maximum Power

74 HP / 55 kWEmissions

UN ECE R96 Stage IIIA, Brazil MAR-1Maximum Torque

221 lb-ft @ 1600 rpm / 300 Nm @ 1600 rpmCompare Models

Maximum Power

1150 HP / 858 kWEmissions

U.S. EPA Tier 2 EquivalentMaximum Torque

3876 lb-ft @ 1400 rpm / 5255 Nm @ 1400 rpmCompare Models

Maximum Power

1050 HP / 783 kWEmissions

U.S. EPA Tier 4 FinalMaximum Torque

3448 lb-ft @ 1200 rpm / 4674 Nm @ 1200 rpmCompare Models

Maximum Power

134 HP / 100 kWEmissions

U.S. EPA & CARB Tier 4 Final, EU Stage VMaximum Torque

406 lb-ft @ 1500 rpm / 550 Nm @ 1500 rpmCompare Models

Maximum Power

121 HP / 90 kWEmissions

UN ECE R96 Stage IIIA, Brazil MAR-1Maximum Torque

369 lb-ft @ 1500 rpm / 500 Nm @ 1500 rpmCompare Models

Maximum Power

134 HP / 100 kWEmissions

U.S. EPA & CARB Tier 4 Final, EU Stage VMaximum Torque

391 lb-ft @ 1500 rpm / 530 Nm @ 1500 rpmCompare Models

Maximum Power

121 HP / 90 kWEmissions

UN ECE R96 Stage IIIA, Brazil MAR-1Maximum Torque

369 lb-ft @ 1500 rpm / 500 Nm @ 1500 rpmCompare Models

Maximum Power

1200 HP / 895 kWEmissions

U.S. EPA Tier 4 FinalMaximum Torque

4056 lb-ft @ 1200 rpm / 5499 Nm @ 1200 rpmCompare Models

Maximum Power

1350 HP / 1007 kWEmissions

U.S. EPA Tier 2 EquivalentMaximum Torque

4548 lb-ft @ 1400 rpm / 6166 Nm @ 1400 rpmCompare Models

Maximum Power

111.3 HP / 83 kWEmissions

UN ECE R96 Stage IIIAMaximum Torque

308 lb-ft @ 1400 rpm / 418 Nm @ 1400 rpmCompare Models

Maximum Power

200 HP / 150 kWEmissions

U.S. EPA & CARB Tier 4 Final, EU Stage VMaximum Torque

609 lb-ft @ 1400 rpm / 825 Nm @ 1400 rpmCompare Models

Maximum Power

142 HP / 106 kWEmissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIAMaximum Torque

411.2 lb-ft @ 1400 rpm / 558 Nm @ 1400 rpmCompare Models

Maximum Power

300 HP / 224 kWEmissions

China Stage II, U.S. EPA Tier 3 Equivalent, EU Stage IIIA EquivalentCompare Models

Maximum Power

320 HP / 240 kWEmissions

U.S. EPA & CARB Tier 4 Final, EU Stage VMaximum Torque

935 lb-ft @ 1400 rpm / 1268 Nm @ 1400 rpmCompare Models

Maximum Power

217 HP / 162 kWEmissions

China Nonroad Stage III, UN ECE R96 Stage IIIAMaximum Torque

663 lb-ft @ 1400 rpm / 900 Nm @ 1400 rpmCompare Models

Maximum Power

275 HP / 205 kWEmissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIAMaximum Torque

774 lb-ft @ 1400 rpm / 1050 Nm @ 1400 rpmCompare Models

Maximum Power

275 HP / 205 kWEmissions

China Nonroad Stage IVMaximum Torque

927 lb-ft @ 1400 rpm / 1257 Nm @ 1400 rpmCompare Models

Maximum Power

416 HP / 310 kWEmissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIAMaximum Torque

1335 lb-ft @ 1400 rpm / 1810 Nm @ 1400 rpmCompare Models

Maximum Power

456 HP / 340 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIVMaximum Torque

1540 lb-ft @ 1400 rpm / 2088 Nm @ 1400 rpmCompare Models

Maximum Power

456 HP / 340 kWEmissions

China Nonroad Stage IVMaximum Torque

1540 lb-ft @ 1400 rpm / 2088 Nm @ 1400 rpmCompare Models

Industrial Diesel Power Units

Cat Industrial Power Units are ready made for irrigation, industrial, mining and other pump applications. Our integrated power units are designed to meet applicable emission standards.

Model

Maximum Power

Emissions

Rated Speed

Maximum Power

2100 HP / 1566 kWEmissions

U.S. EPA Tier 2 Nonroad equivalent emission standards (not currently EPA certified)Rated Speed

1750 rpmCompare Models

Maximum Power

48 HP / 36 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 (Tier 4 Final)Rated Speed

2800 rpmCompare Models

Maximum Power

451 HP / 336 kWEmissions

Brazil MAR-1, UN R96 Stage IIIA, U.S. EPA Tier 3Rated Speed

1800-2100 rpmCompare Models

Maximum Power

536 HP / 400 kWEmissions

Brazil MAR-1, UN R96 Stage IIIA, U.S. EPA Tier 3Rated Speed

1800-2100Compare Models

Maximum Power

577 HP / 430 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIVRated Speed

1800-2100 rpmCompare Models

Maximum Power

690 HP / 515 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIVRated Speed

1800-2100 rpmCompare Models

Maximum Power

540 HP / 403 kWEmissions

China Stage II, U.S. EPA Tier 3 Equivalent, EU Stage IIIA EquivalentRated Speed

1800-2100 rpmCompare Models

Maximum Power

580 HP / 433 kWEmissions

U.S. EPA Tier 4 Final, EU Stage V, Japan 2014 (Tier 4 Final), Korea Stage V, China Nonroad IVRated Speed

1800-2100 rpmCompare Models

Maximum Power

630 HP / 470 kWEmissions

China Stage II, U.S. EPA Tier 3 Equivalent, EU Stage IIIA Equivalent or Non-CertifiedRated Speed

1800-2100Compare Models

Maximum Power

630 HP / 470 kWEmissions

U.S. EPA Tier 4 Final, EU Stage V, China Nonroad Stage IVRated Speed

1800-2000 rpmCompare Models

Maximum Power

800 HP / 597 kWEmissions

China Stage III, U.S. EPA Tier 2 Equivalent, EU Stage IIIA Equivalent or Non-CertifiedRated Speed

1800Compare Models

Maximum Power

800 HP / 597 kWEmissions

U.S. EPA Tier 4 Final, EU Stage VRated Speed

1800Compare Models

Maximum Power

74 HP / 55 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 (Tier 4 Final)Rated Speed

2800 rpmCompare Models

Maximum Power

74 HP / 55 kWEmissions

EU Stage V/U.S. EPA Tier 4 Final/ Japan 2014 (Tier 4 Final)Rated Speed

2200-2400 rpmCompare Models

Maximum Power

950 HP / 709 kWEmissions

U.S. EPA Tier 4 Final, EU Stage VRated Speed

1800 rpmCompare Models

Maximum Power

134 HP / 100 kWEmissions

EU Stage V/U.S. EPA Tier 4 Final/ Japan 2014 (Tier 4 Final)Rated Speed

2000-2200 rpmCompare Models

Maximum Power

1000 HP / 746 kWEmissions

U.S. EPA Tier 4 Final and EU Stage VRated Speed

1800 rpmCompare Models

Maximum Power

108.6 HP / 81 kWEmissions

UN ECE R96 Stage IIIARated Speed

2200 rpmCompare Models

Maximum Power

129.4 HP / 96.5 kWEmissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIARated Speed

2200 rpmCompare Models

Maximum Power

188 HP / 140 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Japan 2014 (Tier 4 Final)Rated Speed

2000 - 2200 rpmCompare Models

Maximum Power

275 HP / 205 kWEmissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIARated Speed

116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpmCompare Models

Maximum Power

302 HP / 225 kWEmissions

U.S. EPA Tier 4 Final, EU Stage V, Japan 2014 (Tier 4 Final)Rated Speed

1800-2200 rpmCompare Models

Maximum Power

416 HP / 310 kWEmissions

Brazil MAR-1, UN R96 Stage IIIARated Speed

1800-2200 rpmCompare Models

Maximum Power

456 HP / 340 kWEmissions

EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014 (Tier 4 Final) and China Nonroad IVRated Speed

1800-2200 rpmCompare Models

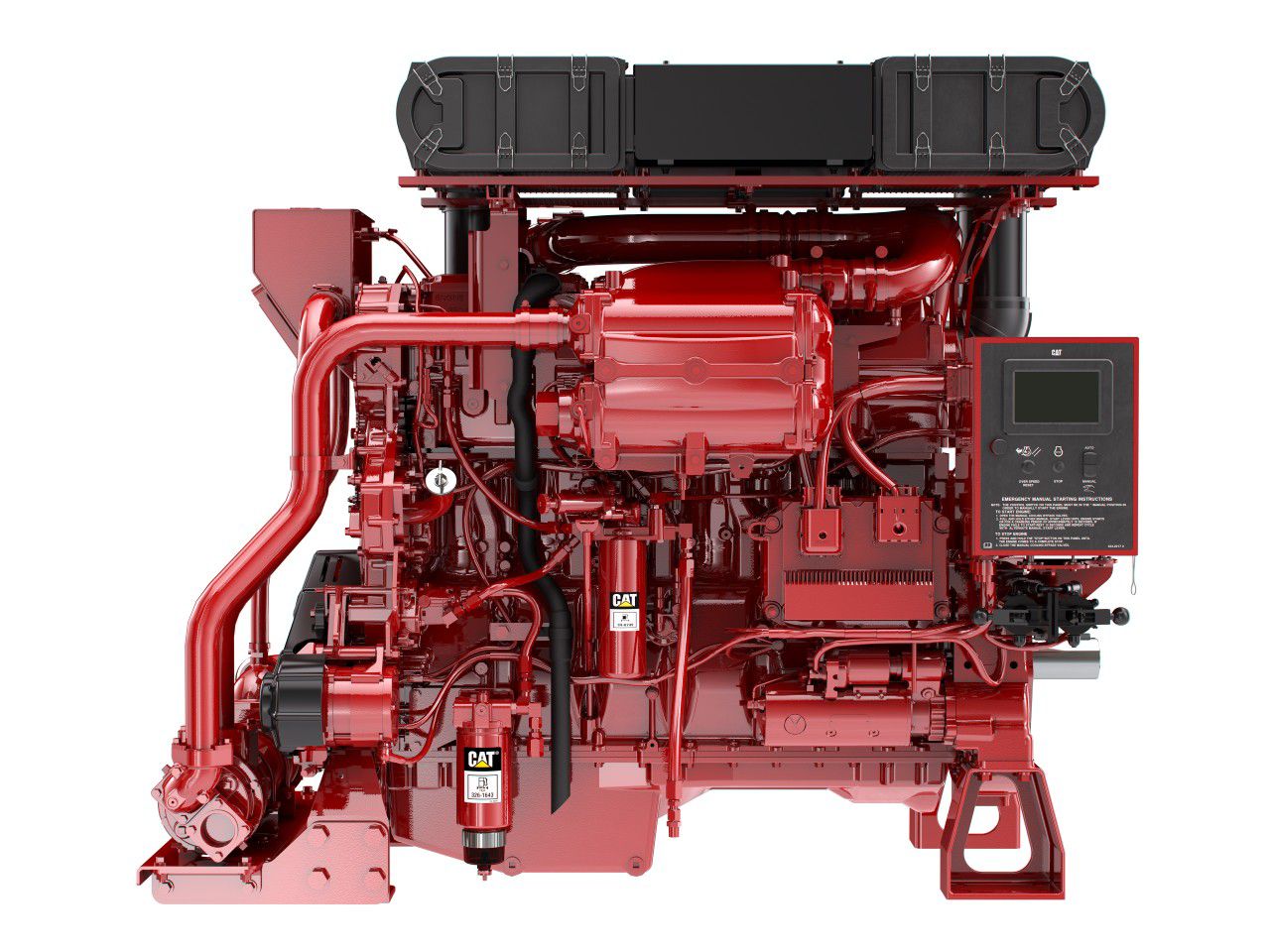

Diesel Fire Pumps

Cat® fire pump engines have a reputation for reliable starts and long efficient service.

Model

Maximum Power

Emissions

Rated Speed

Maximum Power

482 HP / 359 kWEmissions

Non-Certified. Available for global non-regulated areas. FM Approved, UL ListedRated Speed

1750-2300 rpmCompare Models

Maximum Power

1065 HP / 794 kWEmissions

Non-Certified. Available for global non-regulated areas. Not FM Approved, Not UL ListedRated Speed

1460-1750 rpmCompare Models

Maximum Power

1600 HP / 1193 kWEmissions

Non-Certified. Available for global non-regulated areas. Not FM Approved. Not UL ListedRated Speed

1460-1750 rpmCompare Models

Maximum Power

1985 HP / 1480 kWEmissions

Non-Certified. Available for global non-regulated areas. Not FM Approved. Not UL ListedRated Speed

1460-1750 rpmCompare Models

Maximum Power

800 HP / 597 kWEmissions

U.S. EPA Tier 3, Tier 2 or Non-certified emission standards for stationary emergency fire pump engines. FM Approved, UL ListedRated Speed

1500-2100 rpmCompare Models